Production method of reactive epoxy carboxylate compound, resin composition containing the compound, and cured product thereof

A technology of epoxy carboxylate and resin composition, which is applied in the photoplate-making process of pattern surface, photosensitive material and coating of optical mechanical equipment, etc., which can solve the problems of reduced reliability and achieve storage stability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-4

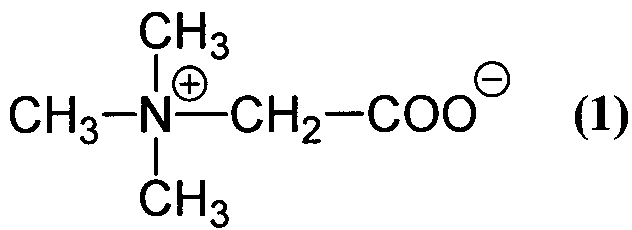

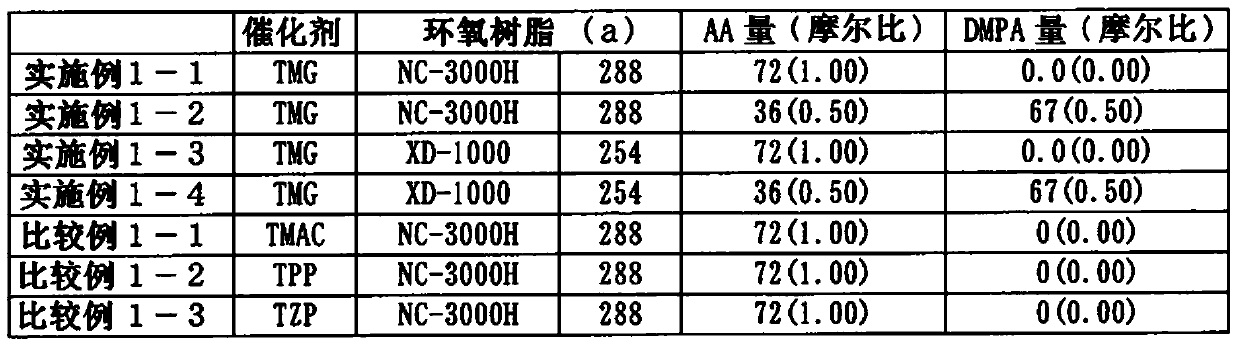

[0125] Embodiment 1-1~1-4: The manufacture of reactive epoxy carboxylate compound (A)

[0126] NC-3000H (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 288 g / equivalent), XD-1000 (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 254 g / equivalent) were added as epoxy resin (a) in the amount listed in Table 1 equivalent), the acrylic acid (abbreviated as AA, Mw=72) of the amount recorded in Table 1 as the compound (b), the dimethylol propionic acid (DMPA, Mw=134 for short) as the compound (c) of the amount recorded in Table 1 ). Add 3 g of trimethylglycine (TMG) as a catalyst, and propylene glycol monomethyl ether monoacetate as a solvent so that the solid content reaches 80% by mass of the reaction solution, and react at 100° C. for 24 hours to obtain a reactive epoxy carboxylic acid Ester compound (A) or reactive epoxy carboxylate compound (A') solution. The next reaction was carried out with the solid content acid value (AV: mgKOH / g) being 5 mgKOH / g or l...

Embodiment 2-1~2-4

[0131] Embodiment 2-1~2-4: Preparation of reactive polycarboxylic acid compound (B)

[0132] In the reactive epoxy carboxylate compound (A) solution obtained in Examples 1-1 to 1-4, add tetrahydrophthalic anhydride (abbreviated as THPA) as polybasic acid anhydride (d) in Table 2 , and propylene glycol monomethyl ether monoacetate as a solvent to make the solid content 65% by mass, and after heating to 100°C, carry out an acid addition reaction to obtain a reactive polycarboxylic acid compound (B) or a reactive polycarboxylic acid Compound (B') solution. Table 1 describes the solid content acid value (AV: mgKOH / g).

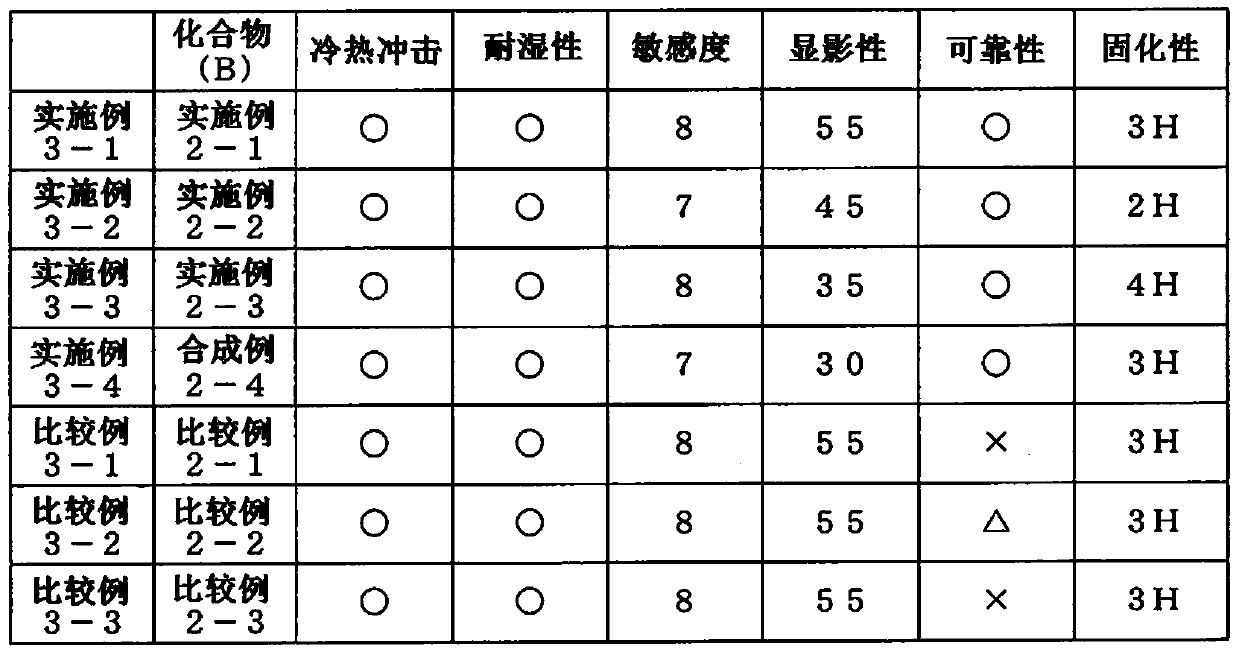

Embodiment 3 and comparative example 3

[0137] Example 3 and Comparative Example 3: Preparation of dry film resist composition

[0138] Add the reactive polycarboxylic acid compound (B) obtained in Example 2 or 54.44 g of the reactive polycarboxylic acid compound obtained in Comparative Example 2, and HX-220 (trade name: Nippon Ka Yakuza Co., Ltd. diacrylate monomer) 3.54 g, 4.72 g of Irugakyua-907 (manufactured by Ciba Seika Chemical Co., Ltd.) as a photopolymerization initiator (D), and 0.47 g of Kayakuer DETX-S (manufactured by Nippon Kayaku Co., Ltd.) , 14.83 g of GTR-1800 (manufactured by Nippon Kayaku Co., Ltd.) as a curing component, 1.05 g of melamine as a thermosetting catalyst, and 20.95 g of methyl ethyl ketone as a concentration adjustment solvent were kneaded by a bead mill to make It is uniformly dispersed to obtain a resist resin composition.

[0139] The obtained composition is uniformly coated on a polyethylene terephthalate film as a support film by a roll coating method, and after passing through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com