an optical cable assembly

A technology of optical cable components and optical fibers, applied in the field of optical cable components, can solve the problems that signals cannot be transmitted from one optical fiber ribbon to another optical fiber ribbon, crossing in up and down directions cannot be realized, signal crossing is inevitable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

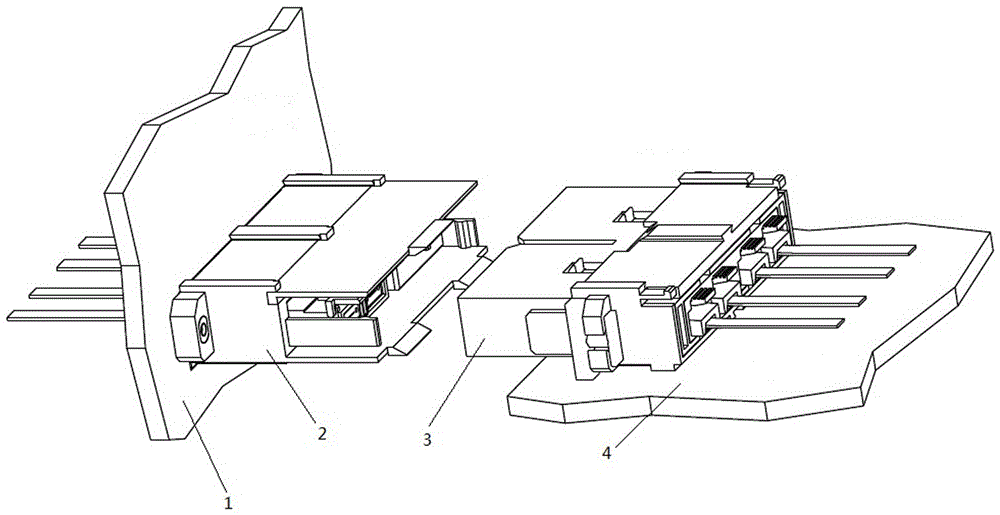

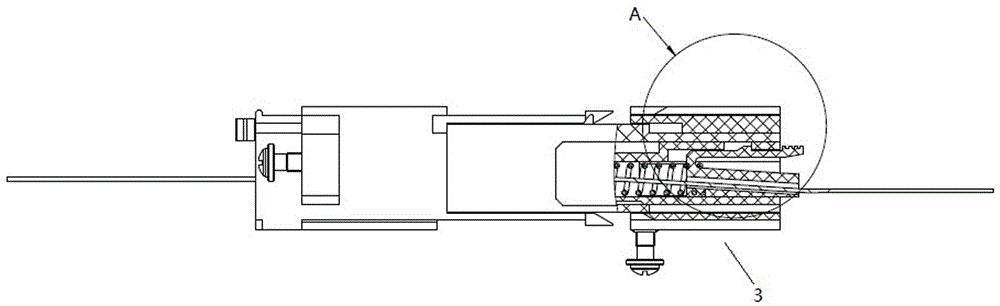

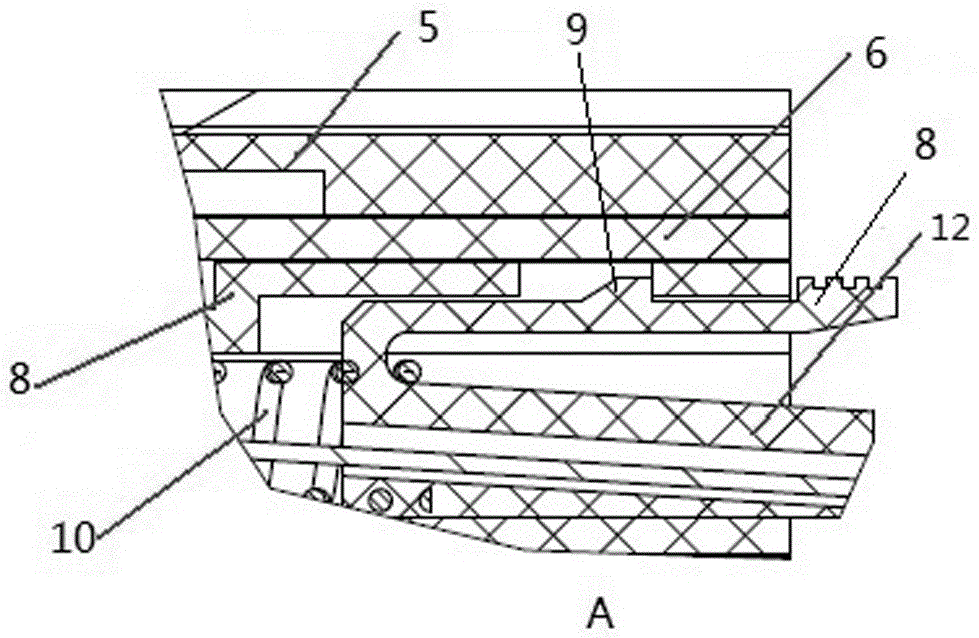

[0026] Examples of fiber optic cable assemblies are Figure 1~15 As shown: the optical cable assembly includes an optical fiber connector and an optical fiber backplane. In this embodiment, the optical fiber connector is a sub-board plug installed on a sub-board in a corresponding cabinet during use. The sub-board plug 3 includes a plug housing and a plug housing The body includes a plug part housing 8, a locking housing 6 and a floating housing 5, wherein the front end of the plug part housing is a plug end, the plug part housing is made of insulating material, and the plug part housing is provided with contacts unit, the contact unit includes a pin body 11 and a limit seat 12 arranged front and rear. In this embodiment, the limit seat is a two-body limit seat, and the pin body includes MT pins. 8. The elastic arm 8 is provided with a locking protrusion 9, and the plug part housing 8 is provided with a card slot that cooperates with the locking protrusion 9, and a first sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com