Packaging film forming device

A forming device and packaging film technology, applied in the field of packaging equipment, can solve the problems of poor forming effect and achieve good forming effect and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

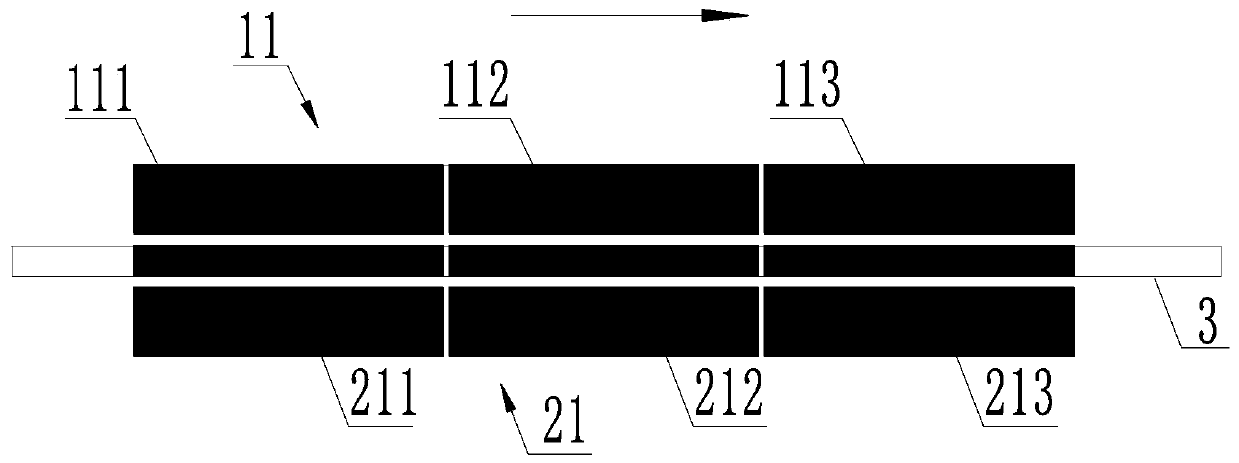

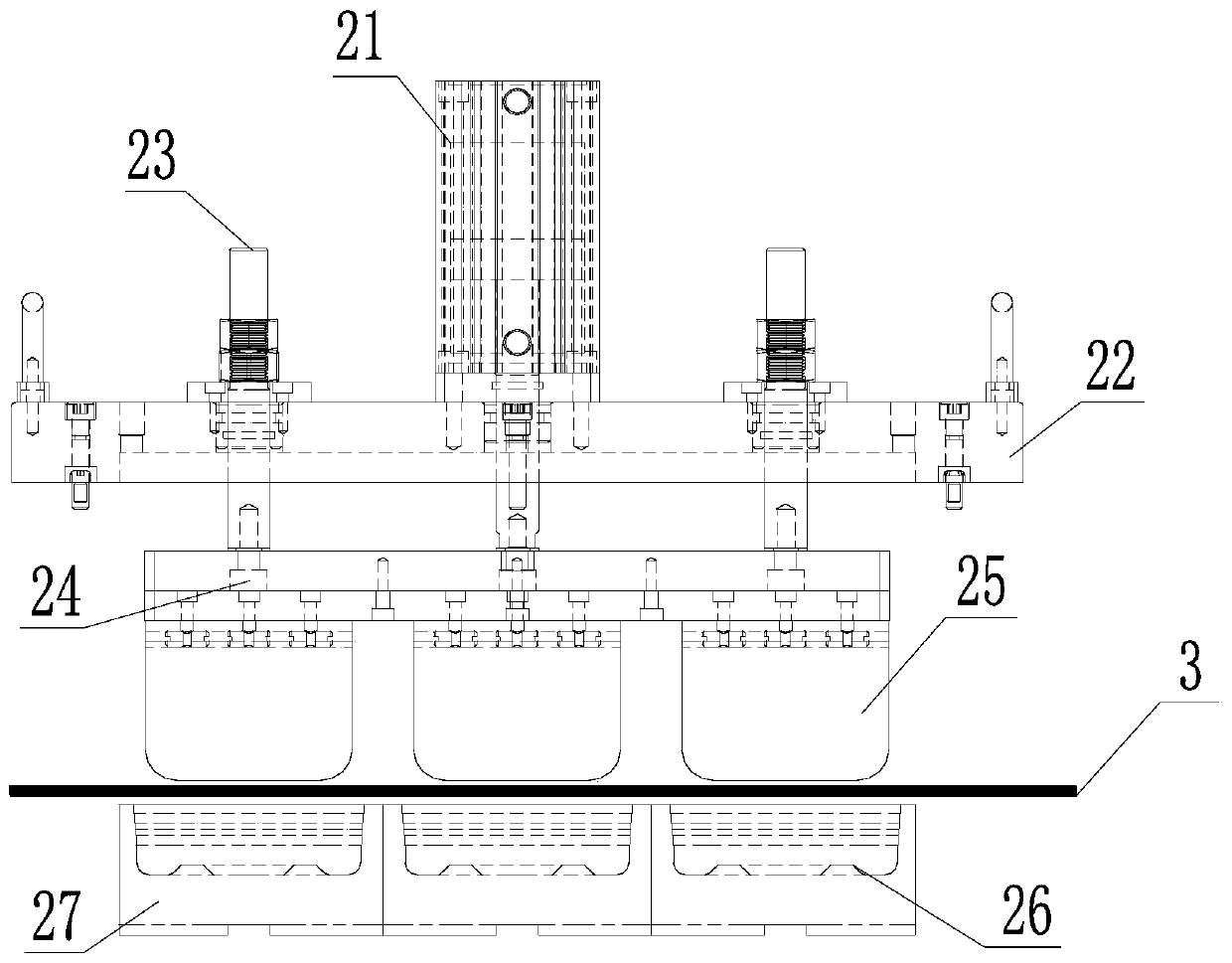

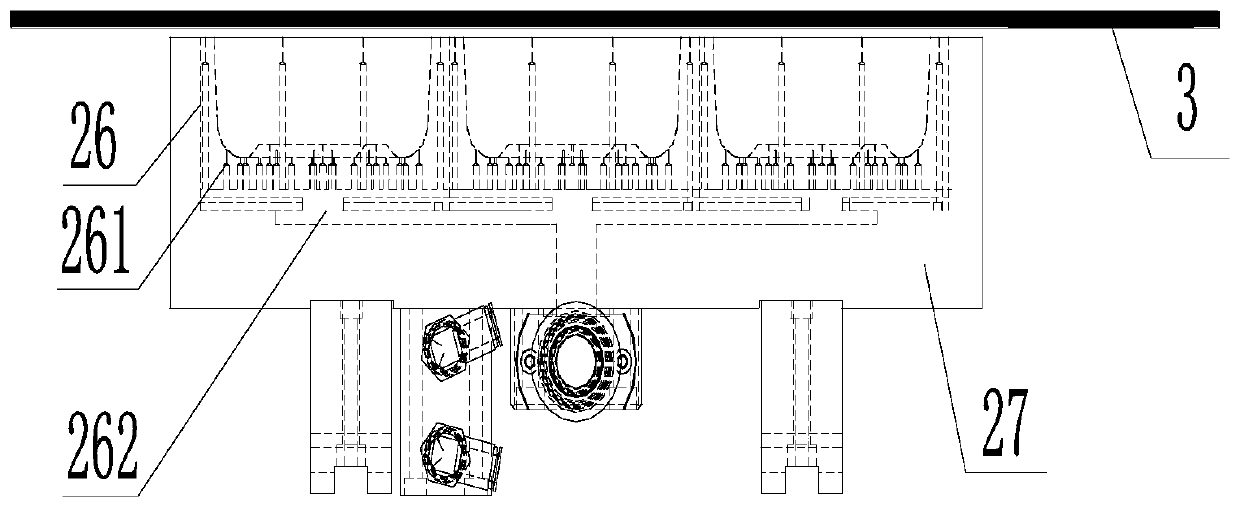

[0020] Such as figure 1 and figure 2 As shown, a packaging film forming device includes three heating mechanisms 1 arranged on the heating station and a forming mechanism 2 arranged adjacent to the three heating mechanisms 1 on the forming station, the heating station and the forming The workstations are adjacent.

[0021] Heating Mechanism 1

[0022] Such as figure 1 As shown, the heating mechanism 1 includes an upper heating chamber 11 and a lower heating chamber 12 which respectively heat the upper and lower sides of the packaging film. , the lower heating chamber 12 can move vertically up and down. When the lower heating chamber moves upward and contacts with the upper heating chamber, the upper and lower heating chambers form a closed space, and the packaging film clamped between them is up and down. Heating on both sides, here the above heating chamber is taken as an example to introduce.

[0023] The upper heating chamber 11 includes first to third heating plates ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap