A photoelastic instrument auxiliary installer

A technology of photoelasticity and installation device, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of lens and gyroscope round head falling off, etc. The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

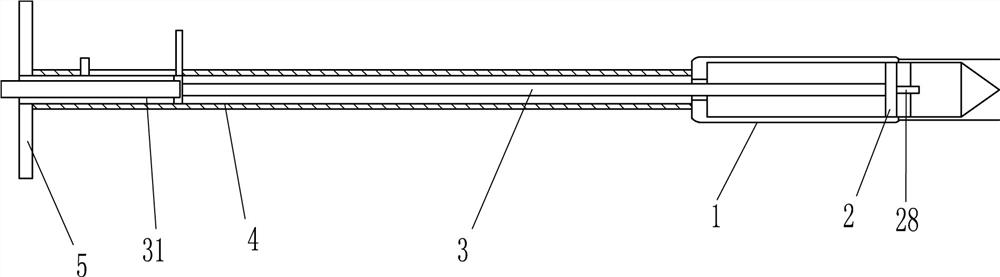

[0021] Refer to attached figure 1 , attached figure 2 And attached image 3 , a photoelastic instrument auxiliary installer, including a cylindrical sleeve 1, a clamping device 2, a push rod 3, a hexagonal rotating rod 31, a sleeve 4 and an annular push plate 5, and the cylindrical sleeve 1 passes through a chute slider The sliding type is provided with a clamping device 2, and the clamping device 2 is used to fix the photoelastic instrument. The cylindrical sleeve 1 is provided with a sleeve 4, and the sliding type is provided with a push rod 3 inside the sleeve 4, and the push rod 3 is connected with the clamp. Tightening device 2 is connected, and sleeve pipe 4 other end is provided with annular push plate 5, has hexagonal groove on push rod 3, and hexagonal turning rod 31 snaps in the hexagonal groove, and hexagonal turning rod 31 passes through annular pushing plate 5.

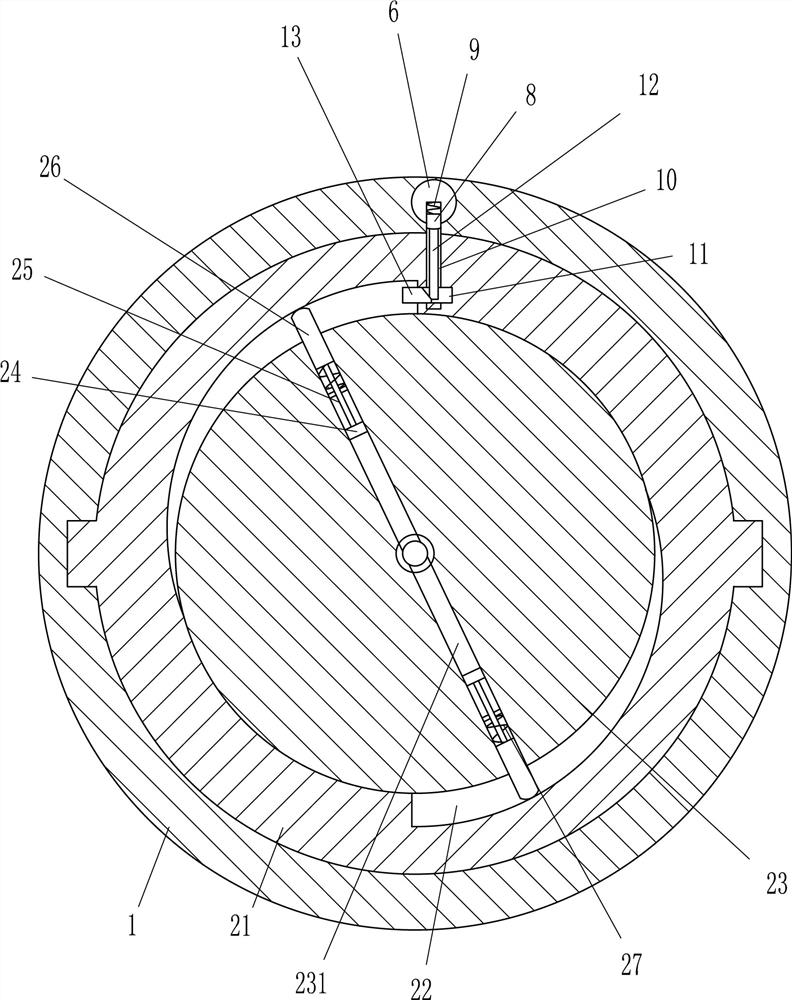

[0022] The clamping device 2 includes a cylindrical slide 21, a cylindrical block 23, a cylindrical...

Embodiment 2

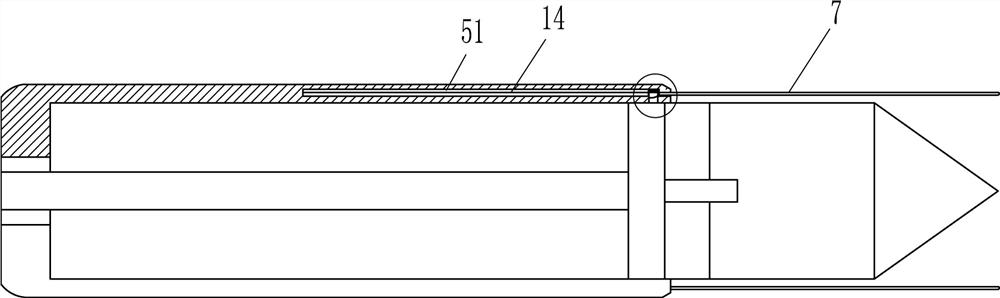

[0025] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 And attached Image 6, on the basis of Embodiment 1, it also includes a sliding block 6, a thimble 7, a second wedge 8, a third elastic member 9, a second push rod 12, a third wedge 13 and an elastic cord 14, and a cylindrical sleeve 1 is symmetrically opened with a word groove 51, and a sliding block 6 is arranged in the word groove 51, and a thimble 7 is arranged on the sliding block 6, and a mounting groove is opened on the side of the sliding block 6 near the cylindrical sliding tube 21, and the installation A second wedge-shaped block 8 is provided slidingly in the groove, and a third elastic member 9 is arranged between the second wedge-shaped block 8 and the installation groove. The third elastic member 9 is a compression spring. The through hole 10 and the tank body 11, the through hole 10 communicates with the tank body 11, the tank body 11 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com