Two stage oxidation process for production of aromatic dicarboxylic acids

A technology of benzenedicarboxylic acid and oxidation catalyst, which is applied in the field of oxidation and can solve the problems of high equipment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

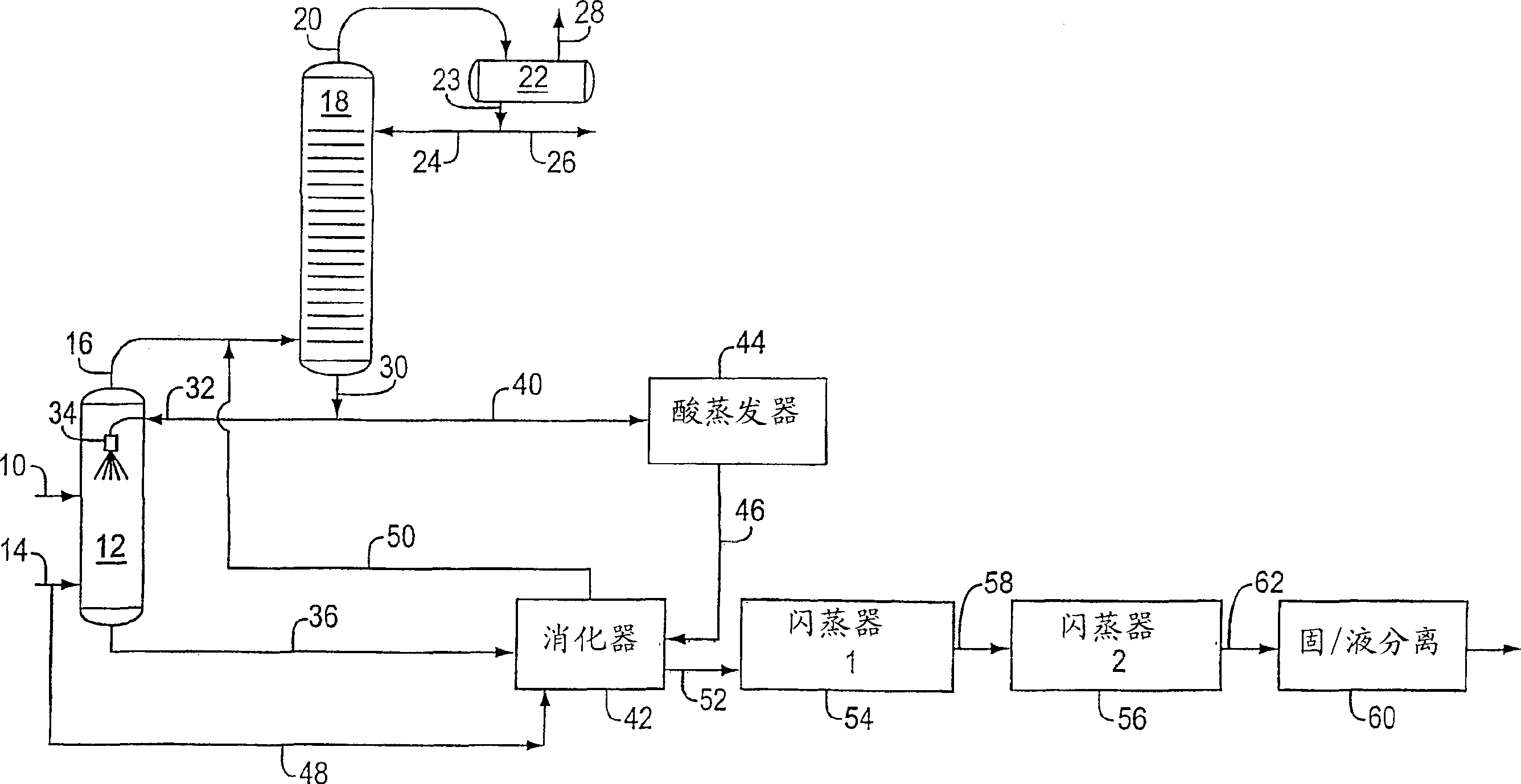

[0033] Our method is further illustrated by the following examples, where parts by weight are parts by weight. P-xylene and acetic acid in which the Co / Mn / Br catalyst system is dissolved are fed to the side of a first oxidation reactor 18 via conduit 10, air is fed to the bottom of this reactor via conduit 14, and the acetic acid containing dissolved catalyst is fed to the side of the first oxidation reactor 18. Speed is 3.1 parts per minute, p-xylene is fed into reactor 12 through conduit 10 at a rate of 0.45 parts per minute, the latter is a cylindrical pressure vessel with a height: diameter ratio of 13.3, and air is fed at a rate of 2.0 parts per minute. Velocity is added through conduit 14 . The gas / liquid oxidation reaction mixture was filled to approximately 85% of the reactor volume, the temperature of the vigorously mixed reaction mixture was 160°C, the pressure was controlled at 6.2 bar absolute (90 psig), and the product in the oxidizer was 30% by weight in aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com