Turbine with variable inlet nozzle geometry

A technology for turbines and turbine impellers, applied in the field of turbochargers and variable turbochargers, which can solve problems such as difficult guarantees and increased nozzle ring loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

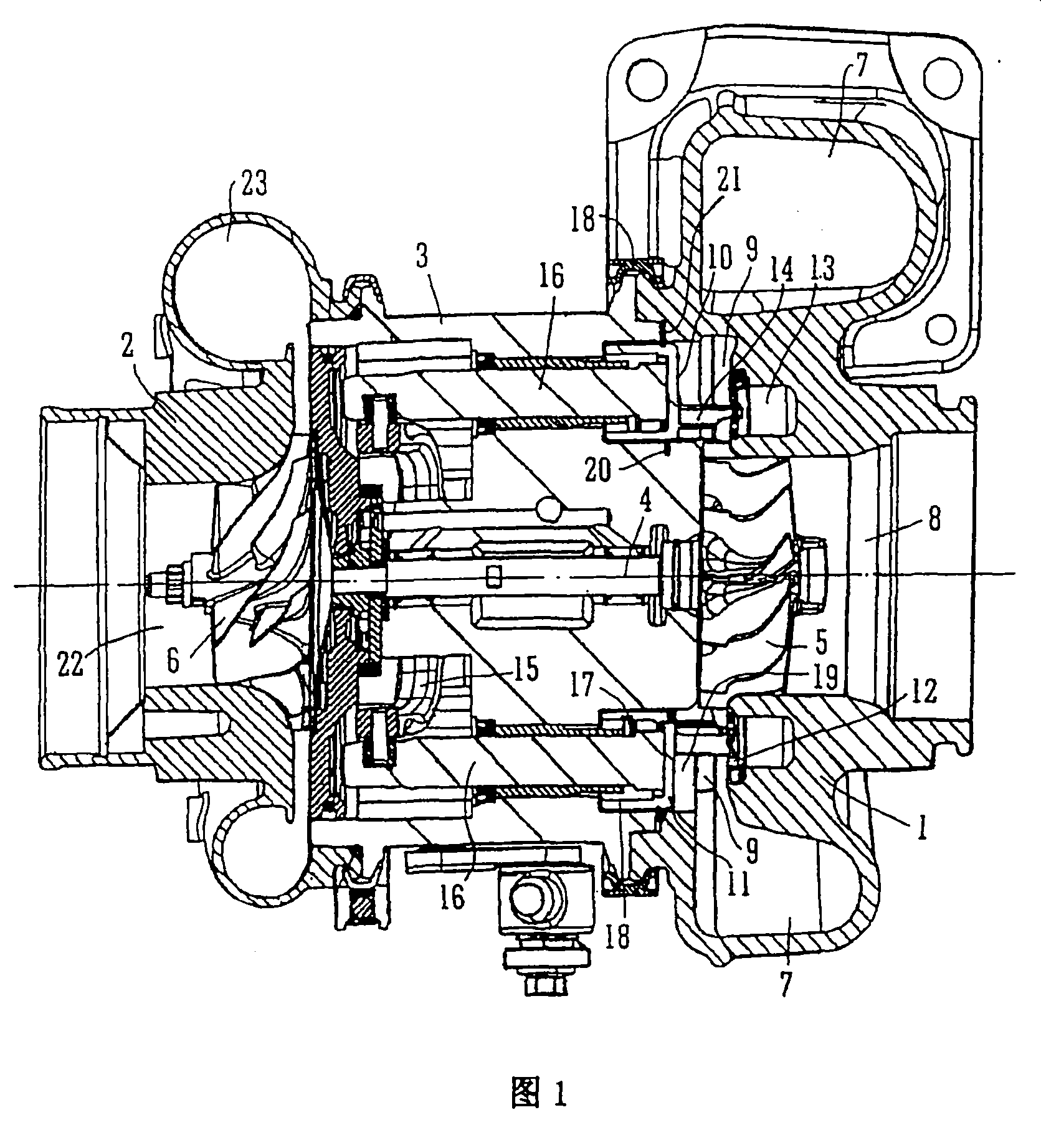

[0065] refer to figure 1 , the variable turbocharger shown includes a variable turbine housing 1 and a compressor housing 2 connected to each other through a central bearing housing 3 . A turbocharger shaft 4 extends from the turbine housing 1 to the compressor housing 2 through the bearing housing 3 . The turbine wheel 5 is mounted on one end of the shaft 4 for rotation in the turbine housing 1 and the compressor wheel 6 is mounted on the other end of the shaft 4 for rotation in the compressor housing 2 . The shaft 4 rotates about a turbocharger axis 4a on a bearing assembly in a bearing housing.

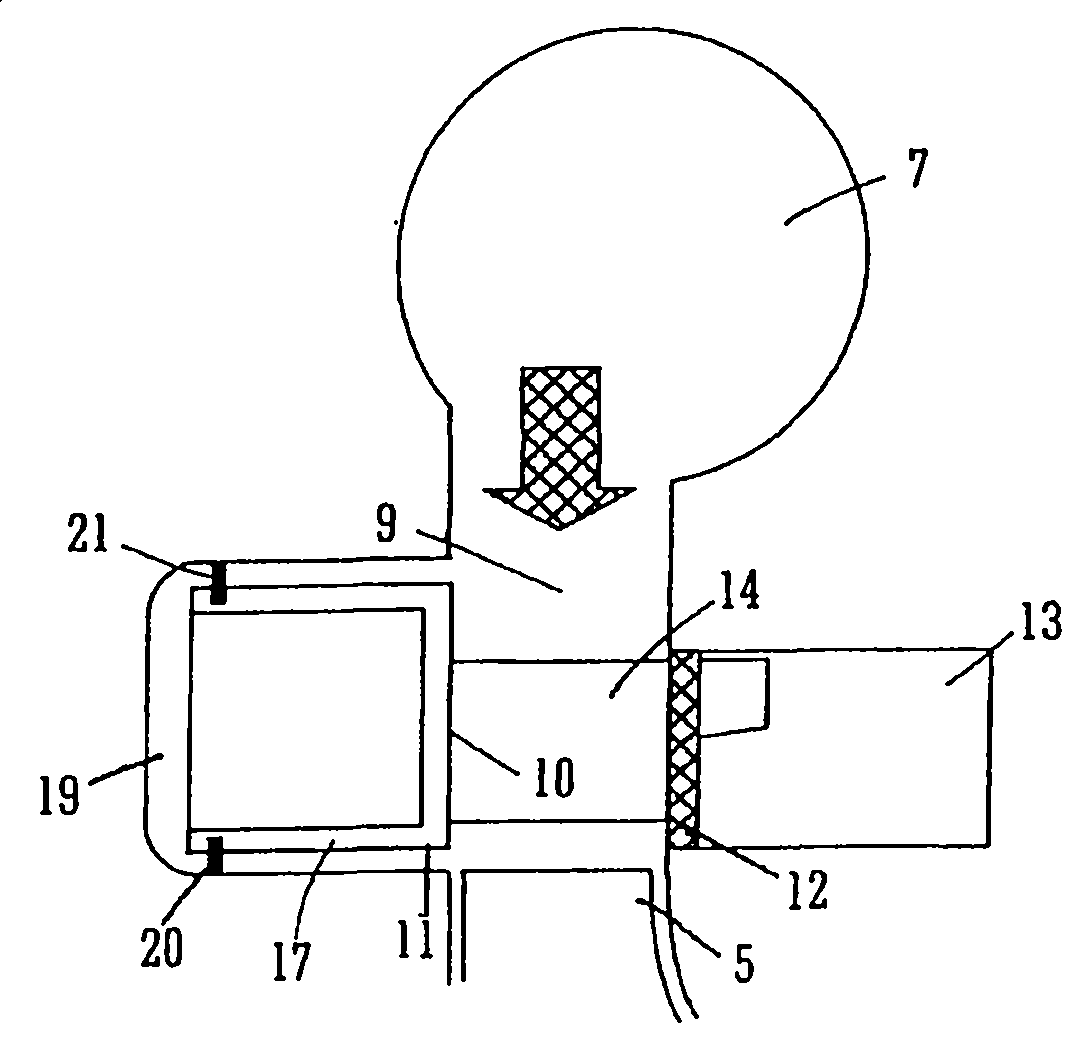

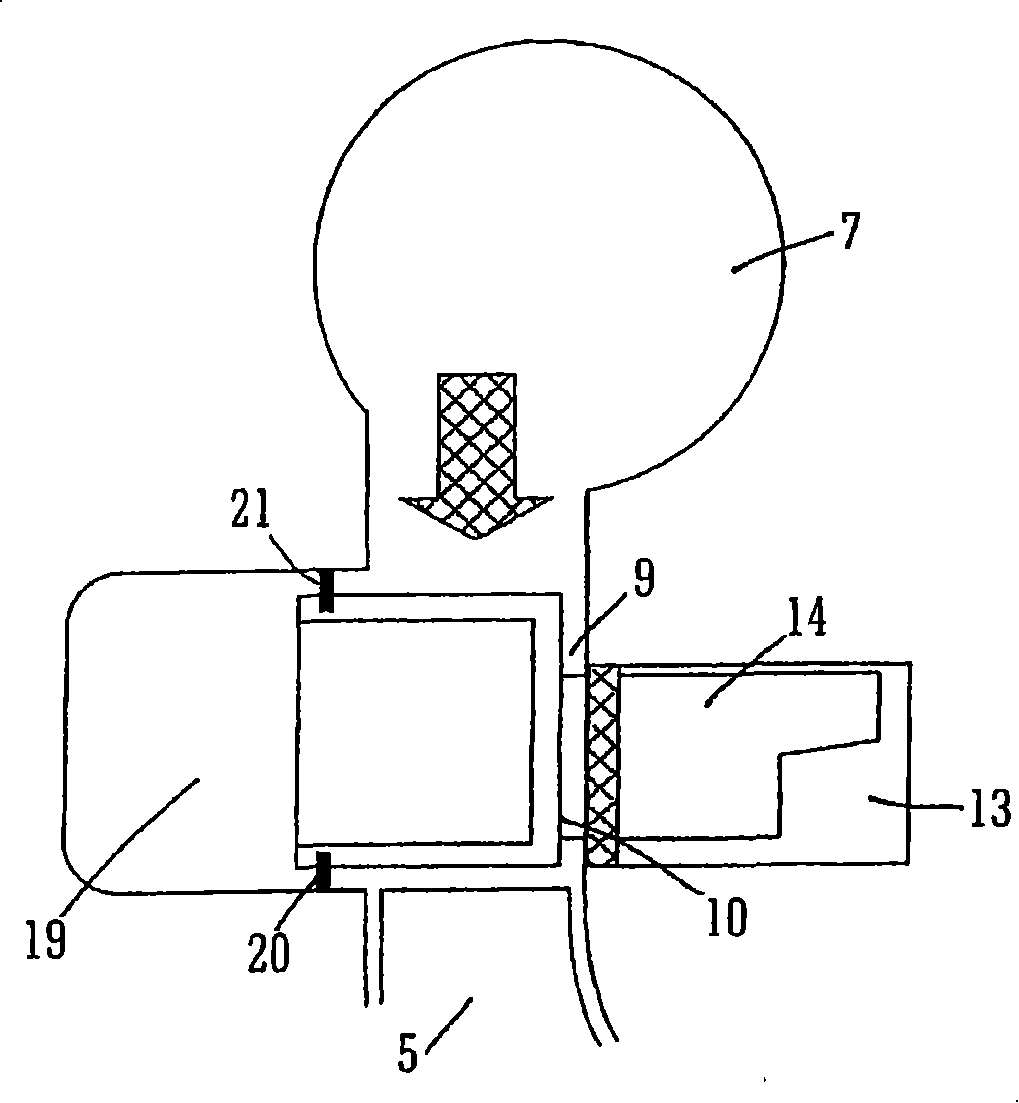

[0066] The turbine housing 1 defines an intake chamber 7 (typically scroll-shaped) into which gas is delivered from an internal combustion engine (not shown). Exhaust gas flows from the inlet chamber 7 to the axial outlet channel 8 via the annular inlet channel 9 and the turbine wheel 5 . The inlet channel 9 is delimited on one side by a radial wall surface 10 of a movable annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com