Concrete double-case subsection beam construction method

A construction method and technology of segmental beams, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high stress on the upper edge of the beam body and impact on the safety of the beam body, so as to ensure safety and operability Strong, Simple Effects

Active Publication Date: 2010-11-24

CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The restoring force during the unloading process of the bridge building machine may cause a large tensile stress on the upper edge of the beam body, thus affecting the safety of the beam body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

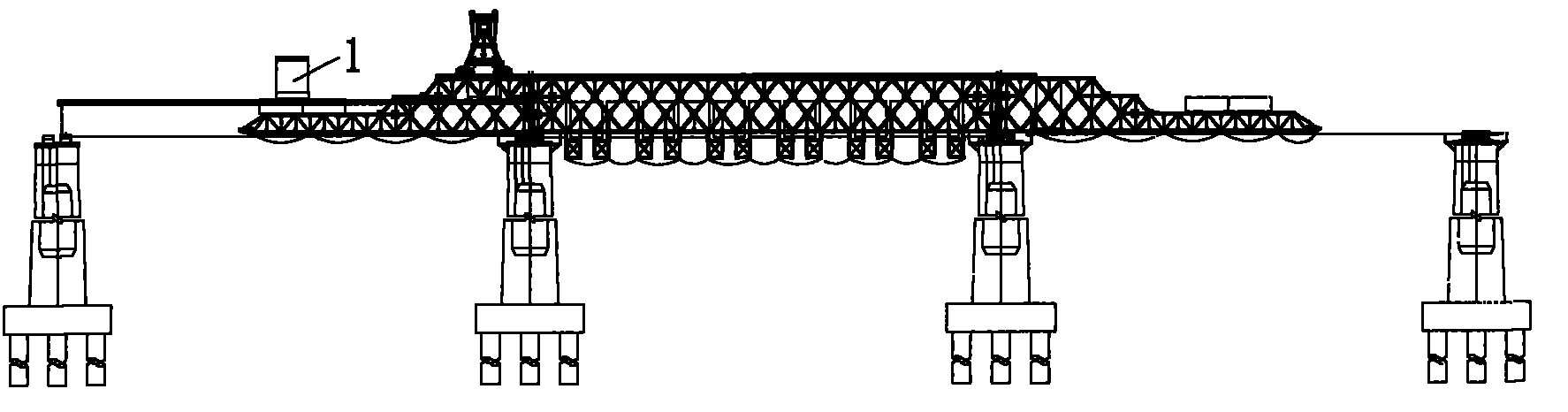

The invention discloses a construction method of a concrete double-box segment girder, more particularly relates to the construction of the bridge segment girder, comprising the following steps: 1) the segment girder is hoisted to position and an oil-jacked support is installed; 2) a wet seam bracket and an internal template as well as an external template are installed, and wet seam concrete is cast; 3) after the wet seam concrete reaches the requirement of design strength, the internal template and the external template are removed and F6 and F5 are stretched; 4) the thickness of the mat ofthe oil-jacked support of the midspan segment girder is reduced by 30mm, and other oil-jacked supports are unloaded according to the parabola of degree 4; 5) after F4 to F1 are stretched, the limitation of a bridge fabrication machine to the girder body is released; 6) steel strands B5 to B1 are stretched; 7) a diaphragm plate is cast and a transversal prestress bundle is stretched; and 8) the bridge fabrication machine is hauled through a hole to carry out the construction of a lower hole girder. The method adopts stepped stretching and sorted unloading to reduce the action of the restoring force of the bridge fabrication machine on the girder body, thus avoiding the occurrence of larger pulling stress of the upper limb stress of the girder body, having simple method and strong operability, and not only being suitable for the prestress stretching of a double-wire simple supporting box girder, but also effectively guaranteeing the safety of the box girder structure.

Description

A construction method of concrete double-box segmental beam technical field The invention relates to the construction of bridge segmental beams, in particular to a construction method for concrete double-box segmental beams. Background technique The 64m Baima River Bridge on the Wenzhou-Fuzhou Railway Passenger Dedicated Line is a typical double-line simply supported box girder bridge. It is designed as a double-width single-box single-chamber section with a beam height of 5m. It is connected by 60cm wide cast-in-place wet joints. There are 12 wet joints in the whole beam, and the weight of the double-width concrete beam is 3200t; After being reviewed by experts, it was changed to a double-line erection scheme, and the construction method of "prefabricated segmental hoisting + in-situ cast-in-place wet joints + prestressed tensioned beams" was adopted. MZ3200t bridge-building machine was used for construction of this beam. Since segmental girder installation, wet joint po...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01D21/00

Inventor 秦顺全刘幸福陶建山卫启阳龚辉忠刘爱林李顺清朱武华李雄活

Owner CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com