Artificial marble having various designs and process for preparing the same

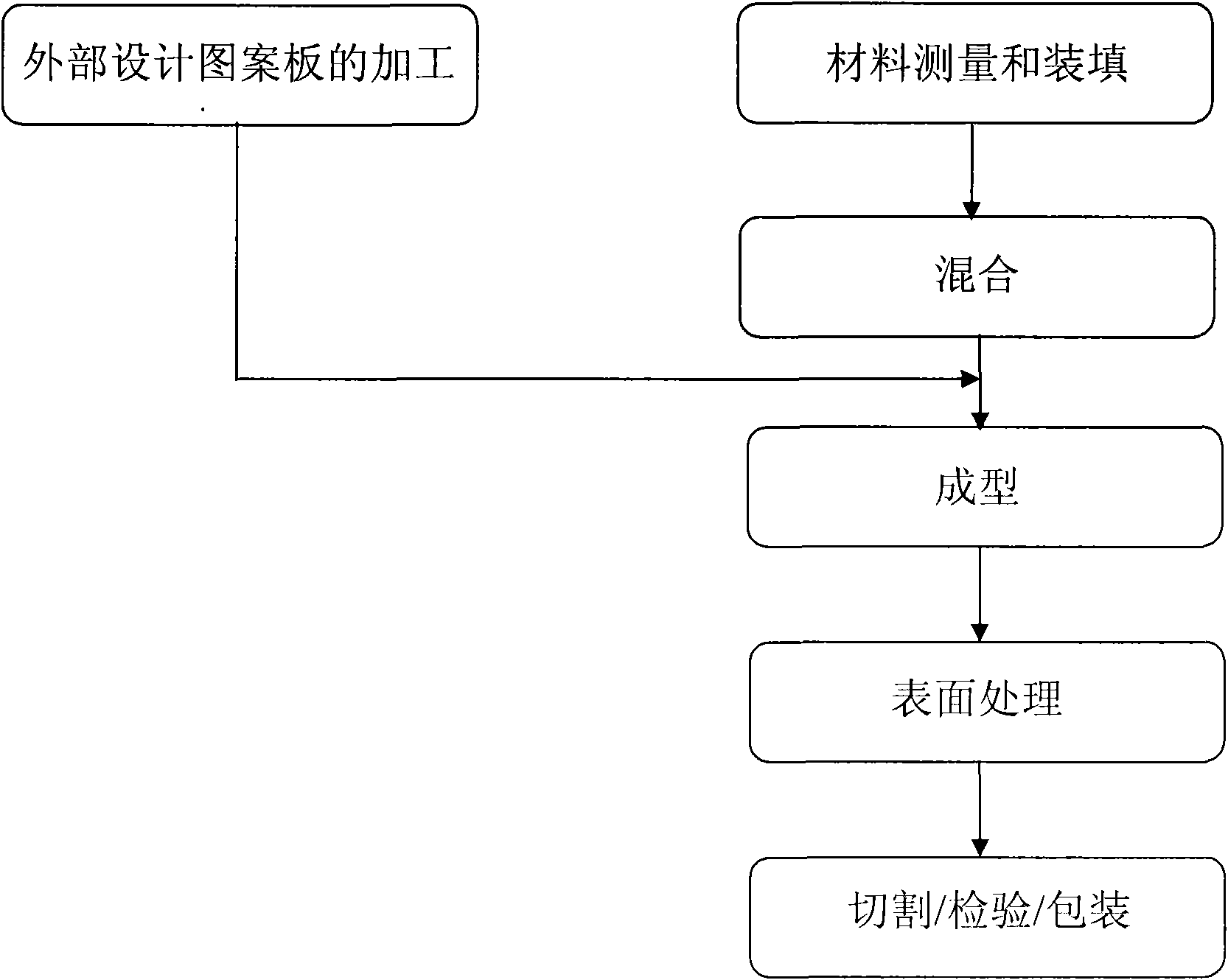

An artificial marble and pattern technology, applied in the direction of imitating natural patterns, special patterns, household appliances, etc., can solve problems such as the limitations of external design patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

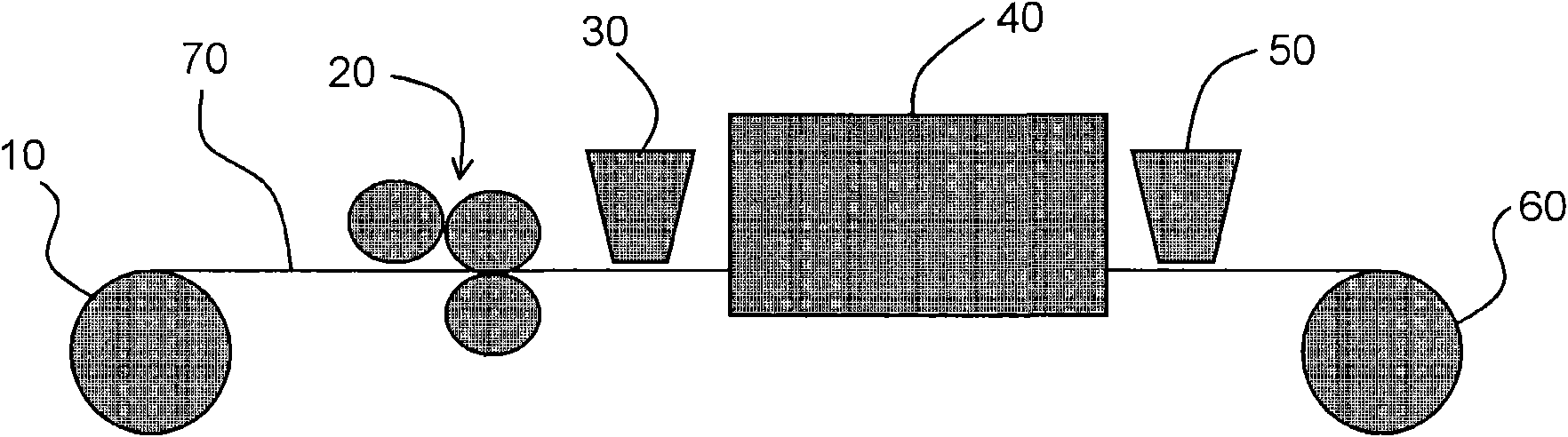

Method used

Image

Examples

Embodiment 1

[0040] A cement-based artificial marble was prepared by using colored glass chips and natural marble chips.

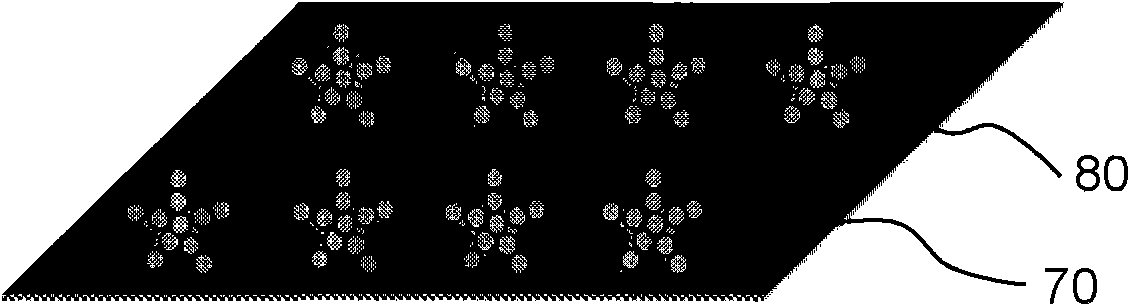

[0041] First, after placing the pre-designed star-shaped screen on the PET film, PVC sol was poured on the screen. Then, the screen was rolled up with a rubber roller so that the PVC sol was transferred onto the PET film to have a star pattern.

[0042]Subsequently, after sprinkling colored glass chips having a diameter of 3 mm to 6 mm on the PET film, the PET film was shaken to remove those redundant colored glass chips scattered on specific portions of the PET film where no PVC sol was applied. Then, the PET film was baked in an oven at a temperature of 180° C. for about 5 minutes to gel the PVC sol. After completion of the gelation of the PVC sol, non-adhered fragments of colored glass were removed again by shaking the PET film.

[0043] The obtained PET sheet was put into a mold having a length of 450 mm, a width of 450 mm, and a thickness of 30 mm, with the stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com