Manufacturing method of a cross-linked foam

A manufacturing method and foam technology, applied to home appliances, other home appliances, footwear, etc., can solve problems such as staining, reduced productivity, and high difficulty, and achieve the effects of reducing manufacturing costs, high production rates, and preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

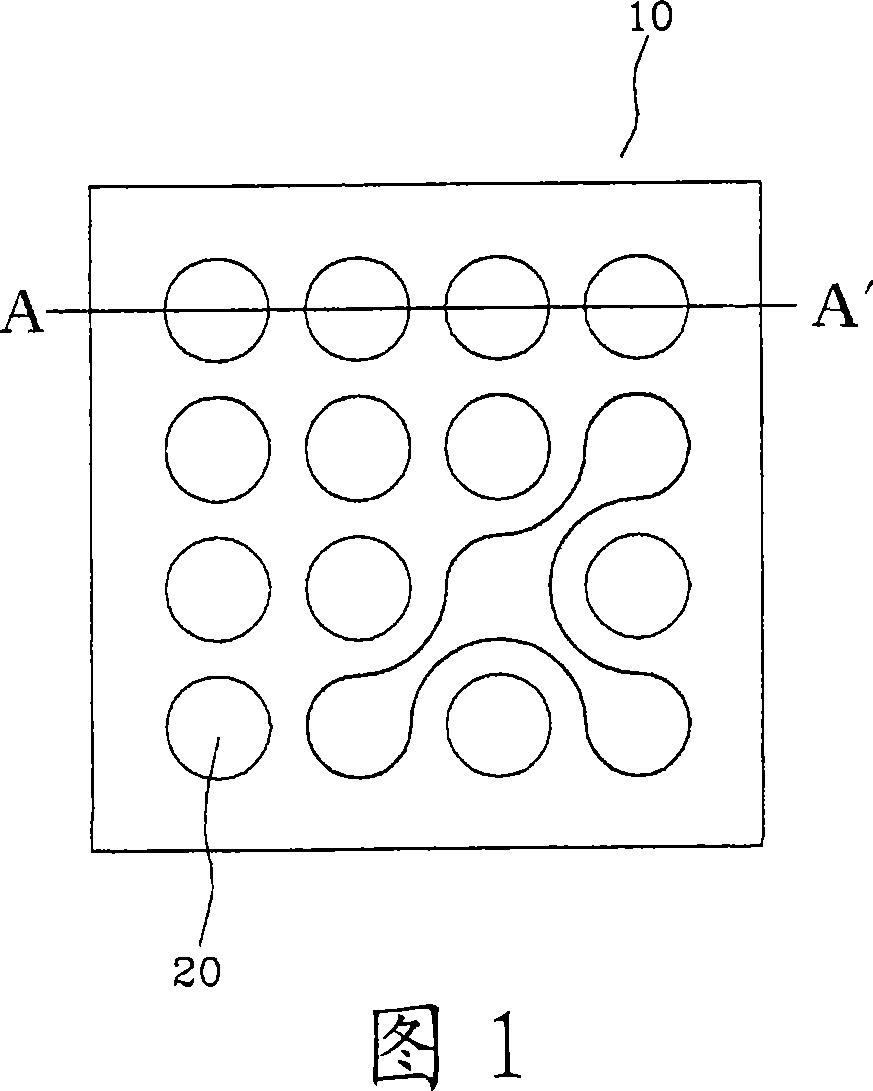

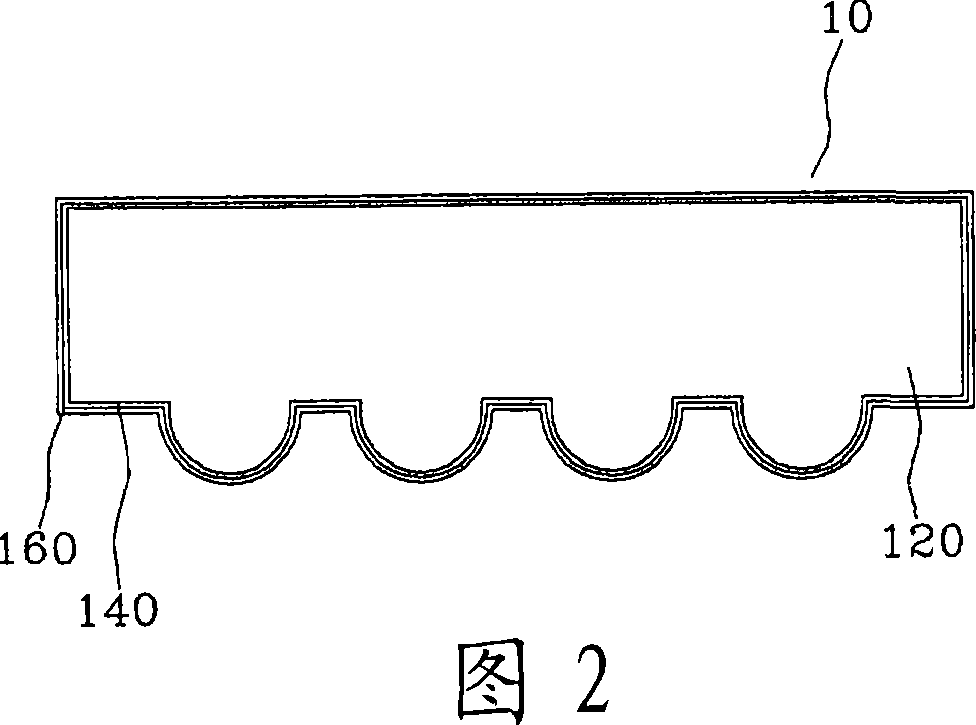

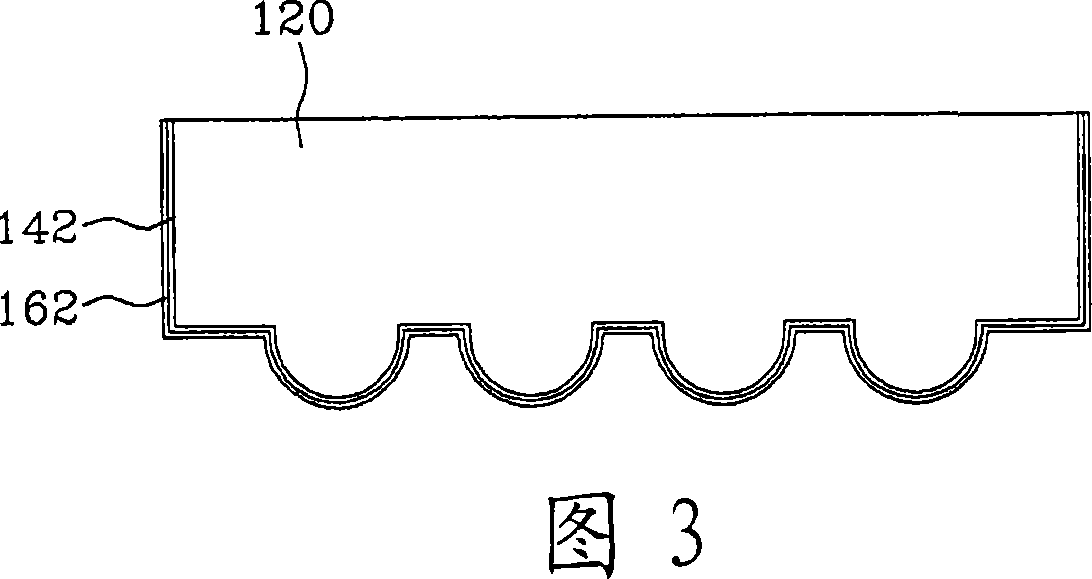

[0058] Reference will now be made in detail to the preferred embodiments of the invention which are illustrated in the accompanying drawings.

[0059] The present invention mainly includes the step of processing the foam material, the step of arranging the processed foam material in a molding mold, and the step of cross-linking and foaming the arranged foam material. The present invention may also include the steps of exposing specific portions of the foam and reshaping the foam.

[0060] In the step of processing the foamable material, the foamable material for the foam body to become the final foam body and the foamable material for the skin covering the surface of the final foam are formed in a state where cross-linking and foaming are suppressed. have a specific shape. At this time, the foamable material for the skin contains a pigment and has a film shape. In the step of arranging the processed foamable material, the processed foamable material is correctly placed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com