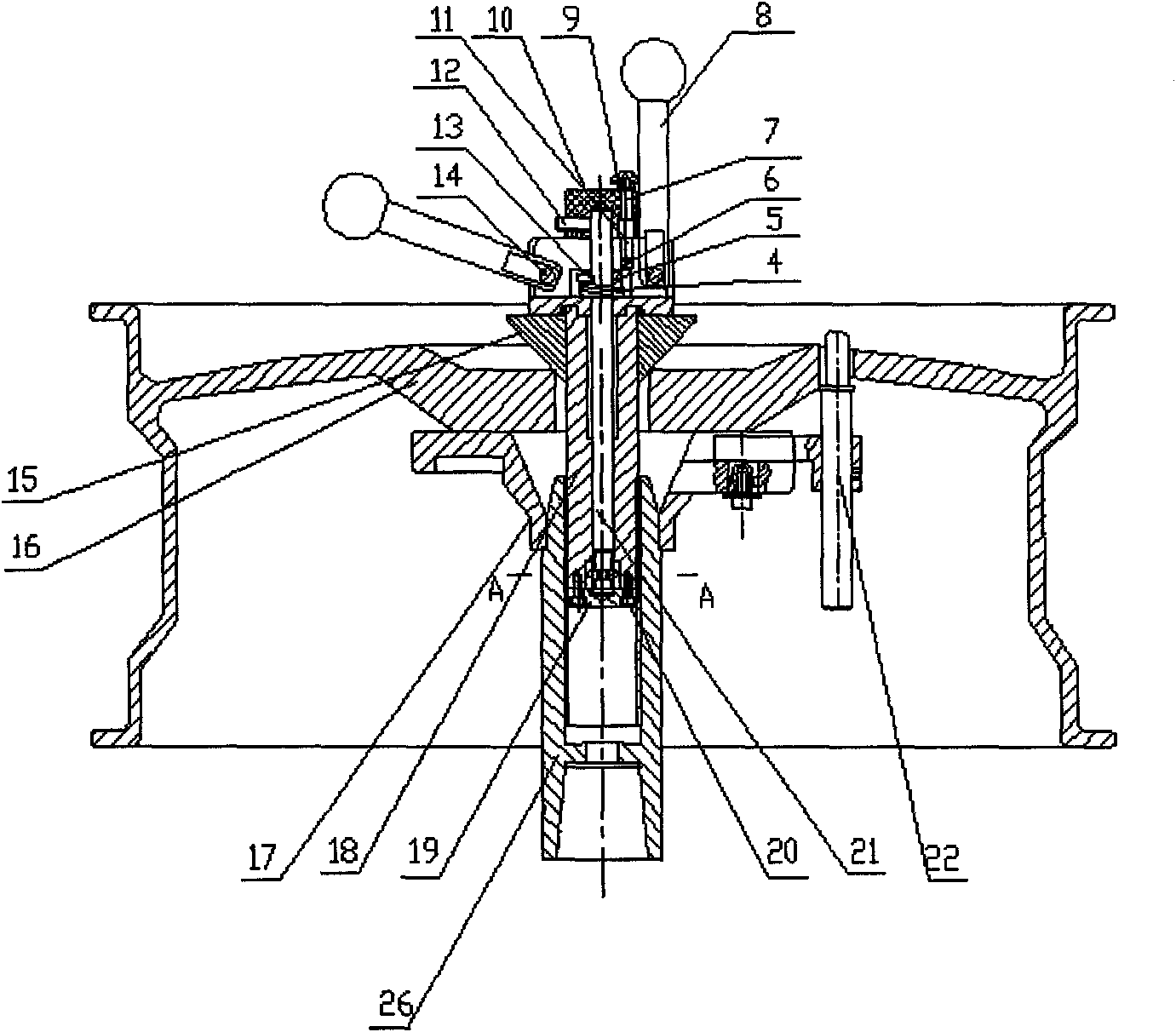

Quick-locking device

A locking device and fast technology, applied in tire installation, transportation and packaging, wheel assembly and disassembly equipment, etc., can solve problems affecting tire disassembly, low operation efficiency, large rotation range, etc., to achieve accurate operation process and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

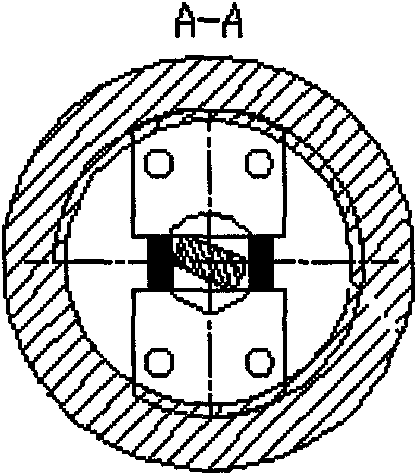

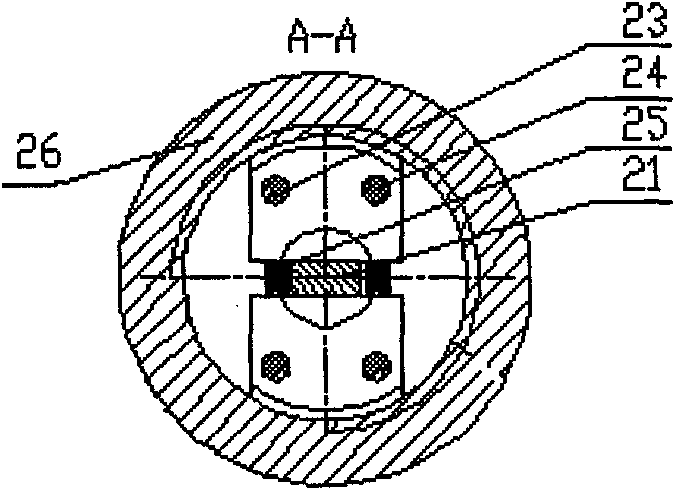

[0012] The main shaft sleeve 1 of the quick locking device and the main equipment are fixed by bolts; the connecting shaft 2 is integrated with the main reduction box and connected with the locking device 3; the locking device 3 is placed in the pallet assembly 17, and the pallet assembly is fixed on the connection On the shaft 2; the torsion spring 4 is hung on the set screw 13, and the lock pin 11 is arranged on the spring 6; the sleeve 5 is fixed on the rotating pin 21 by the set screw; the pressing cap 9 is locked and fixed on the unlocking pin 7, so that the lock pin 11 breaks away from the hole originally contained in the knob 10, and the torsion spring 4 drives the rotating pin 21 to rotate, and at this moment the T-shaped threaded block 23 opens. The handle 8 is fixed on the locking device 3 through the handle pin 14, the tray assembly 17 is welded to the T-shaped threaded sleeve 26, and is welded to the locking sleeve assembly 18 at the same time, the T-shaped threaded...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap