Light guide plate and backlight module group

A technology of backlight module and light guide plate, applied in the field of light guide plate and edge light type backlight module, can solve the problem of uneven brightness at the edge of the visible area of 10 of the backlight module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The invention relates to a backlight module and a light guide plate included in the backlight module; in particular, a backlight module using light emitting diodes and a light guide plate included in the backlight module.

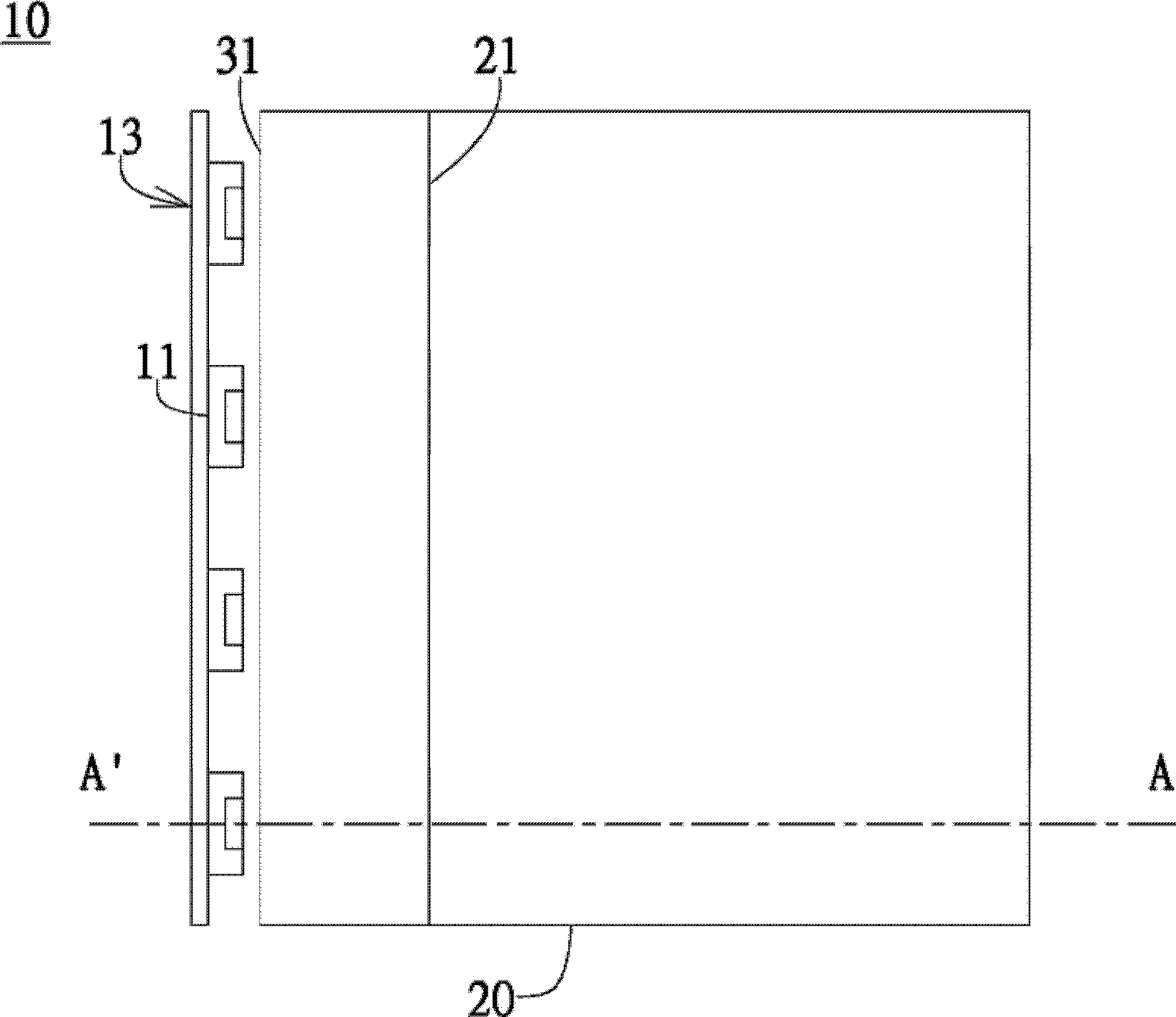

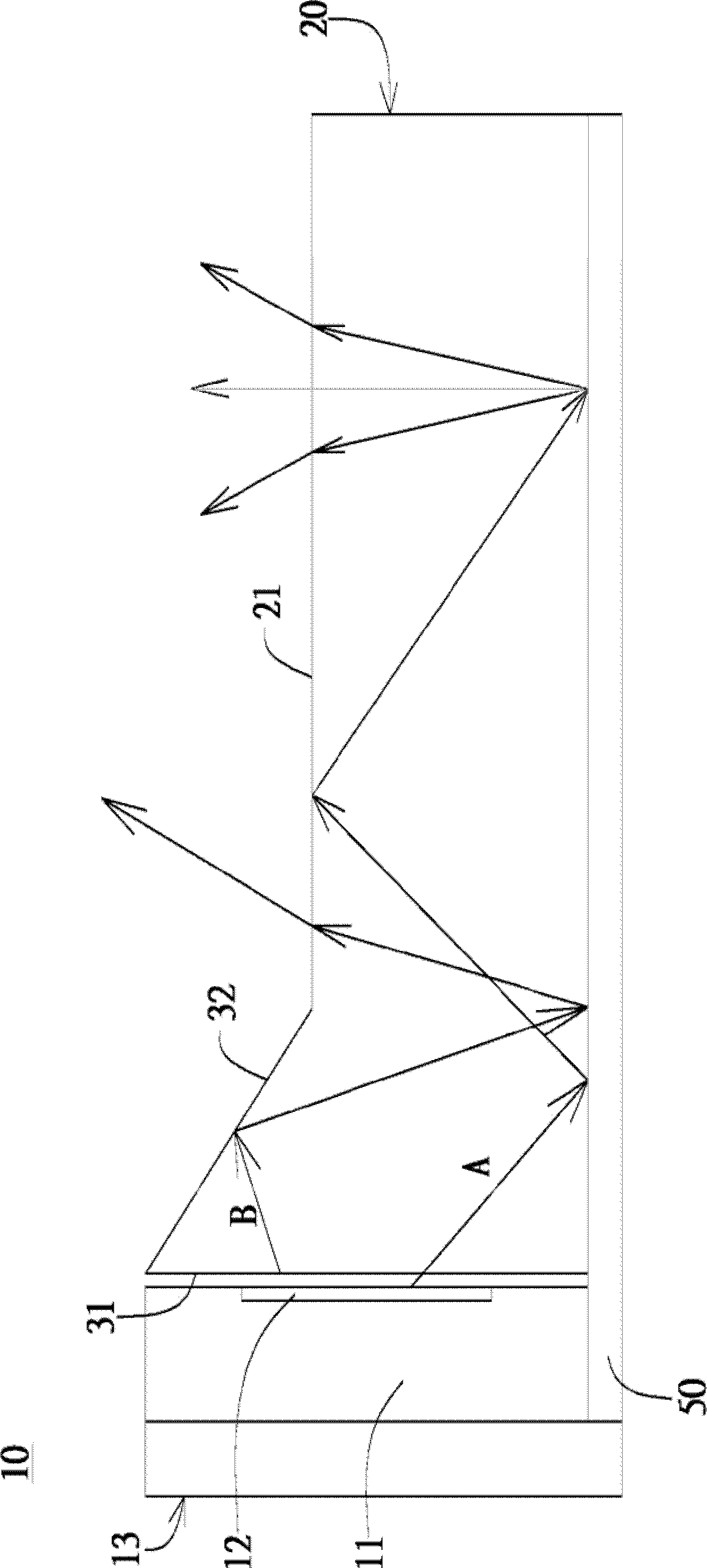

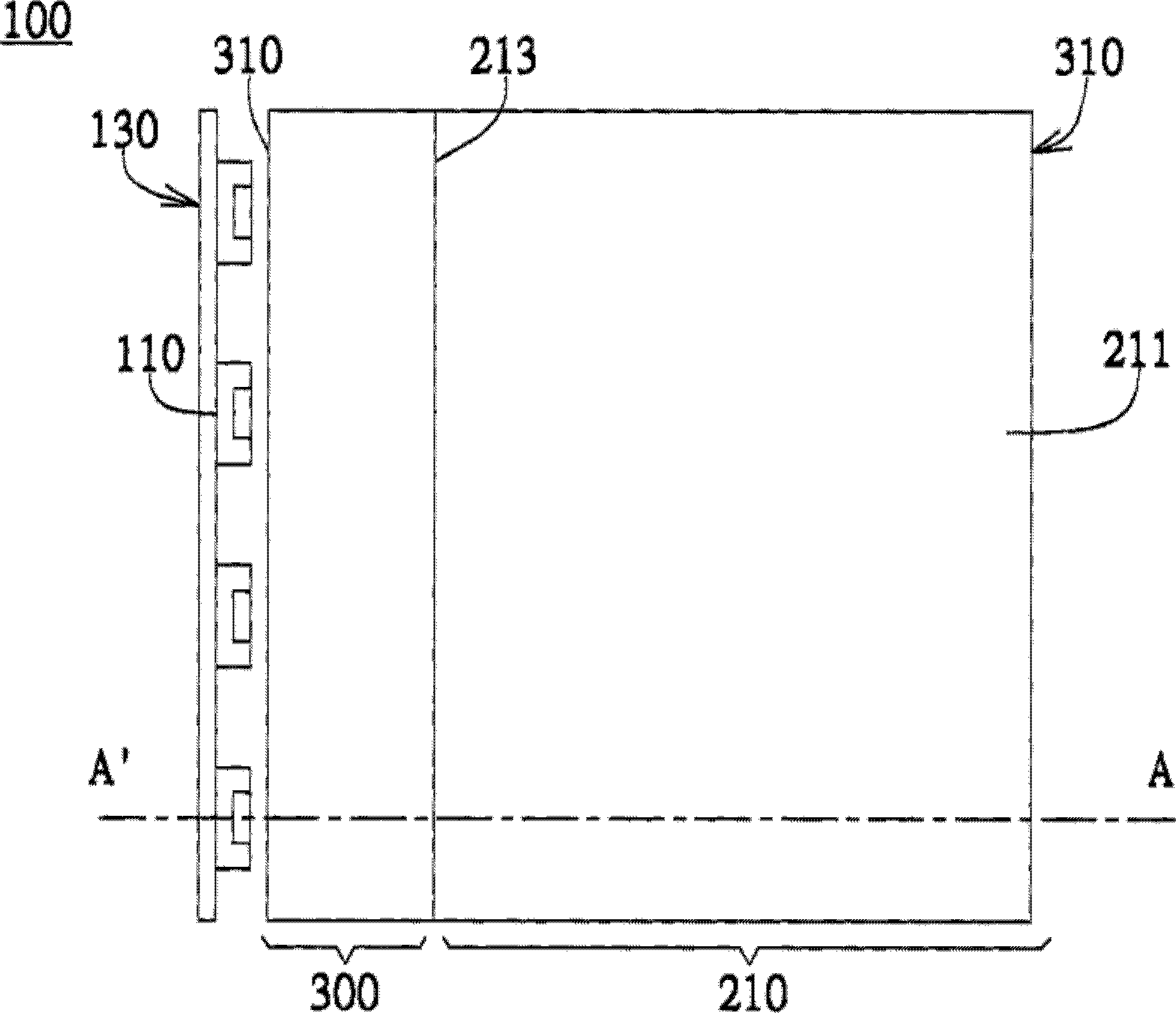

[0063] Figure 2A Shown is the top view of the backlight module 100 of the present invention, and Figure 2B for Figure 2A The shown backlight module 100 is a cross-sectional view produced according to the section line AA'. Please also refer here Figure 2A and Figure 2B , the backlight module 100 of the present invention includes a light bar 130 equipped with a plurality of light emitting elements 110 and a light guide plate 200 . The light guide plate 200 includes a body 210 and a bent light incident portion 300 , wherein the light emitting element 110 is disposed on a side of the light guide plate 200 corresponding to the bent light incident portion 300 and emits light to the light incident end surface 310 of the bent light incident portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com