Light emitting diode crystal grain and manufacture method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low light extraction efficiency and uneven current distribution in light-emitting diode crystal grains, so as to improve light extraction efficiency and increase uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with specific examples.

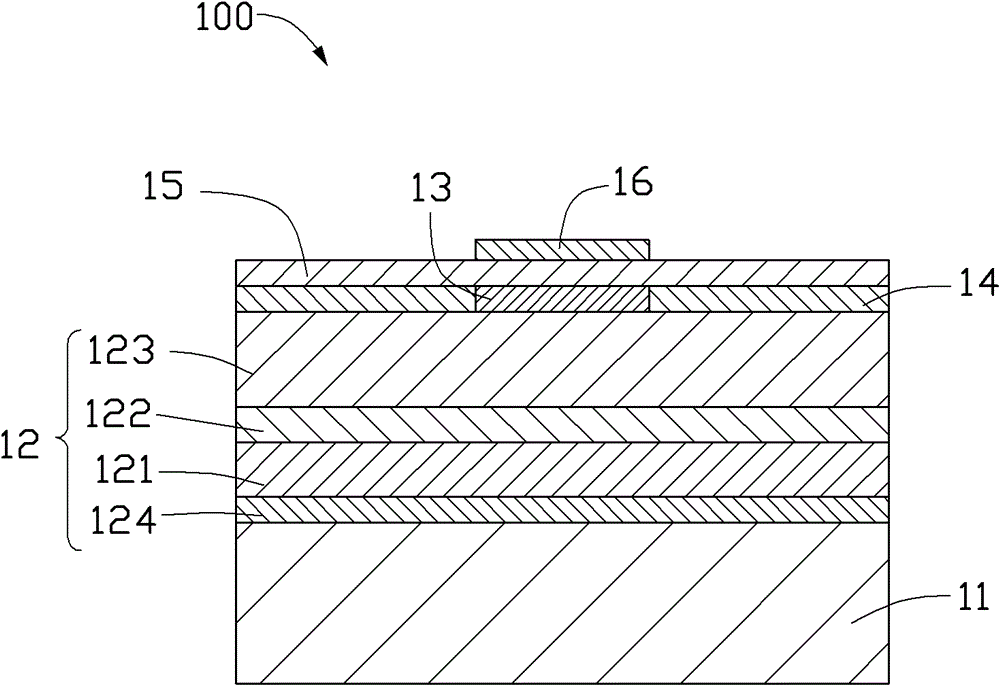

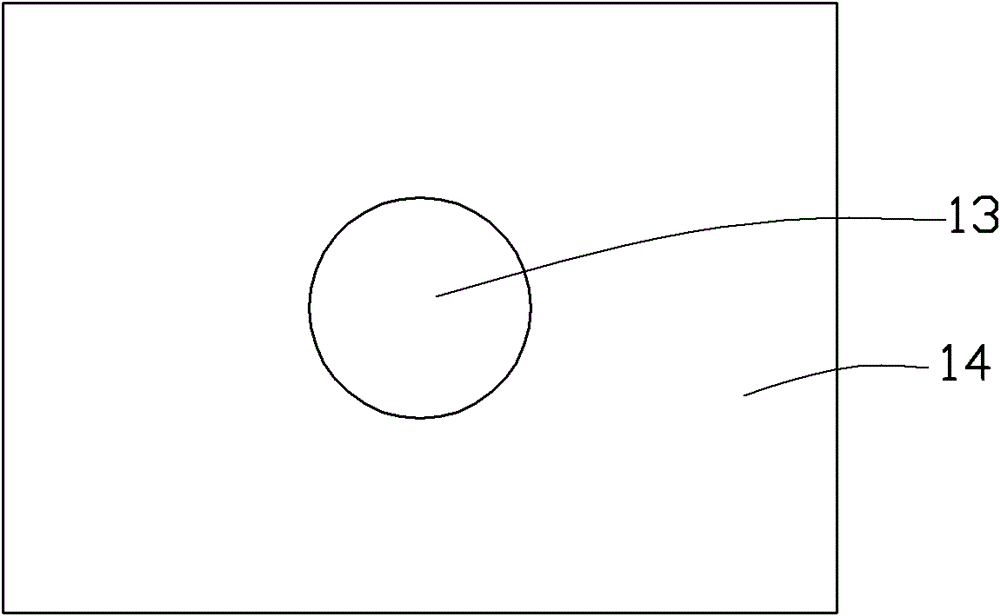

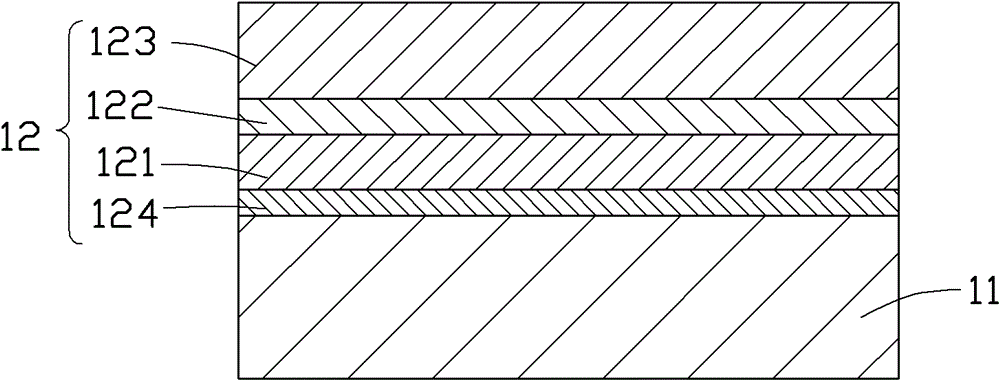

[0028] See figure 1 The light emitting diode die 100 provided by the embodiment of the present invention includes a substrate 11 and a semiconductor light emitting structure 12 disposed on the substrate 11 . A metal layer 13 and a buffer layer 14 are disposed on the surface of the semiconductor light emitting structure 12 , wherein the buffer layer 14 is disposed around the metal layer 13 . A transparent conductive layer 15 is provided on the surface of the metal layer 13 and the buffer layer 14 . An electrode layer 16 is provided on the surface of the transparent conductive layer 15 .

[0029] The substrate 11 is made of a material with high thermal conductivity, which can be a substrate made of metal materials such as copper, aluminum, nickel, silver, gold, or an alloy formed by any two or more metals, or a substrate with good thermal conductivity. Ceramic substrates such as silicon sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com