Painting apparatus

A paint and container technology, applied in the field of application equipment, can solve the problems of wasting time and high risk of paint splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

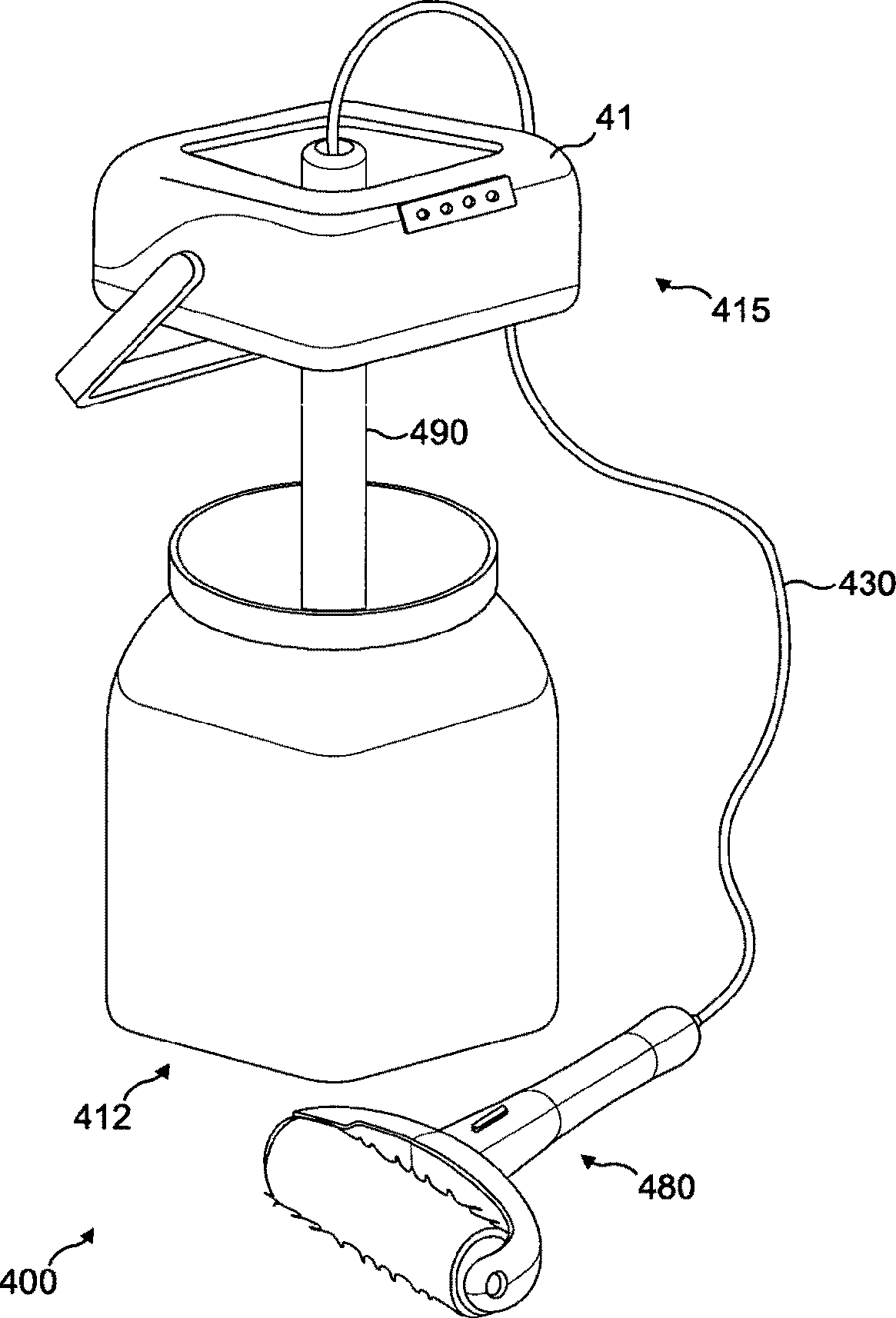

[0017] figure 1 A prior art applicator device 400 is shown including a paint container 412 , closure module 415 , dip tube assembly 490 and roller assembly 480 . The dip tube assembly is fluidly connected to the roller assembly 480 through a conduit 430 . Such a device is described in GB2448578.

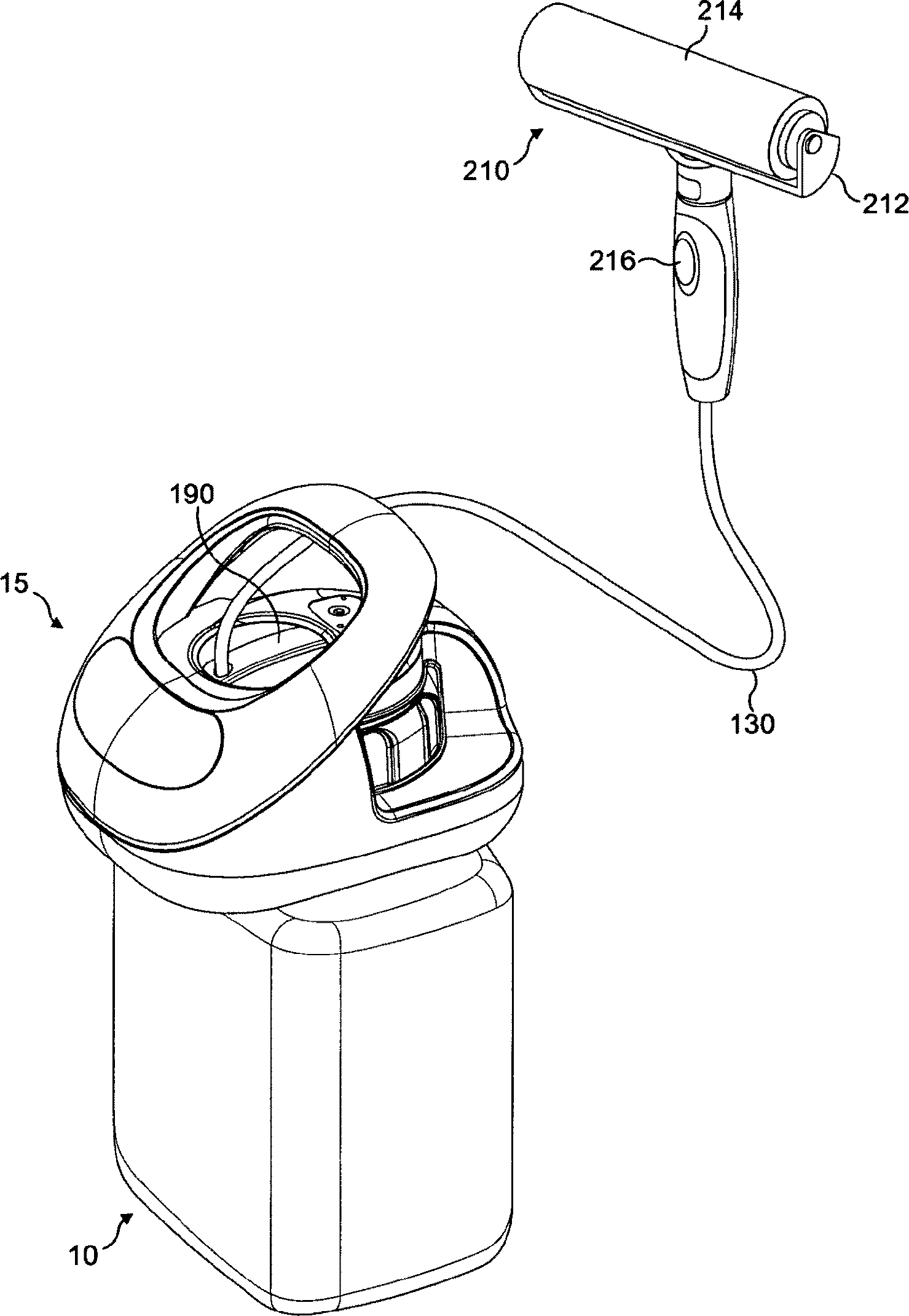

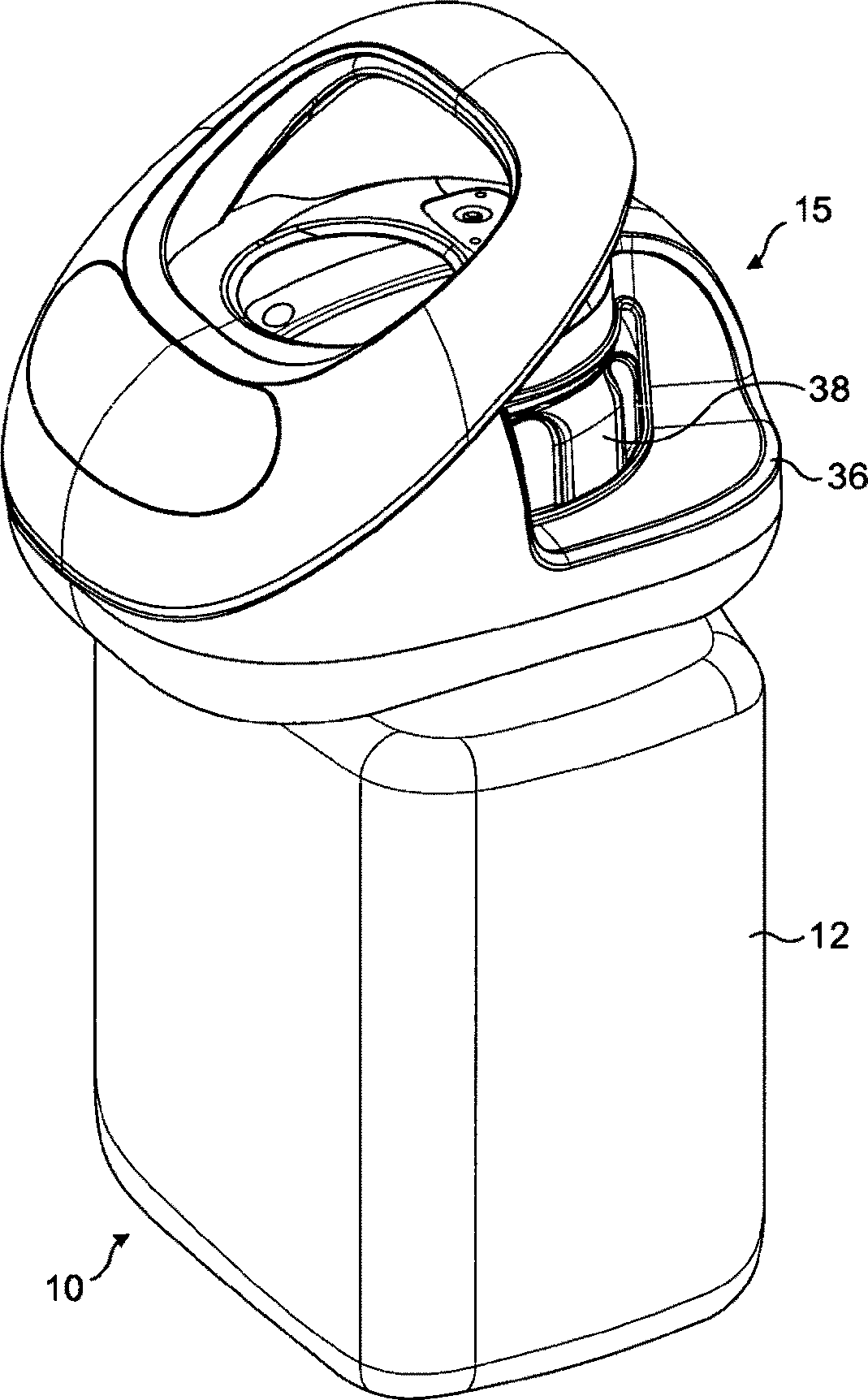

[0018] refer to Figures 2 to 22 , which show the application device 10 of the present invention, which includes a paint container 12 , a closure module 15 , a dip tube assembly 190 and a roller assembly 210 . Dip tube assembly 190 is fluidly connected to roller assembly 210 through conduit 130 .

[0019] The roller assembly 210 includes a roller cage 212 containing a roller 214 and a switch 216 .

[0020] The paint container 12 includes a body 14 , a collar 16 , a handle 18 and a removable closure 20 . The body 14 has an inwardly tapering neck portion 22 and an upstanding rim portion 24 . Upstanding rim portion 24 has a rim 25 defining a container aperture 26 ( Figure 4 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap