Surface polishing method and surface polishing device of thin-wall long and narrow ceramic tube

A technology for surface polishing and ceramic tubes, applied in the field of ceramic tube processing, can solve the problems of low production efficiency, brittle materials, fragile and other problems, and achieve the effects of high processing yield, good polishing quality and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

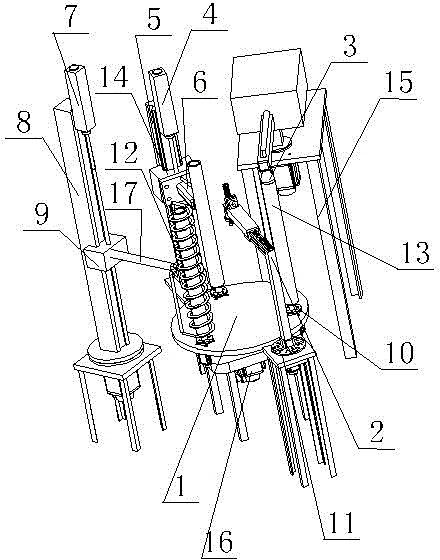

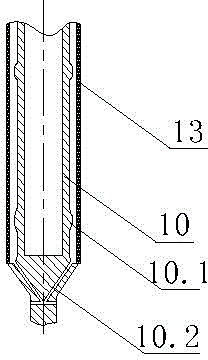

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-2 Shown, a kind of thin-wall narrow and long ceramic tube surface polishing method comprises the following steps:

[0024] 1) Control the pick-up manipulator to grab the ceramic tube through the control system, place the workpiece vertically and coaxially fit it on the mandrel of the first station of the workbench;

[0025] 2) Fill the gap between the ceramic tube and the mandrel at the first station with the low-temperature alloy through the sprue of the pouring system, and solidify the ceramic tube and the mandrel into a whole after the low-temperature alloy is solidified;

[0026] 3) The control system controls the rotation of the working turntable, and places the ceramic tube at the second station; the motor drives the mandrel to rotate, and at the same time, the control system controls the polishing head to move up and down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com