Nylon yarn plying and spandex yarn empty package integrated texturing machine

A technology of nylon yarn and spandex yarn, which is applied in the field of nylon and spandex air-packed yarn, can solve the problems that two strands of nylon yarn and one strand of spandex yarn cannot be completed in one step, and achieve the goal of improving the economic benefits of the enterprise, reducing equipment costs, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

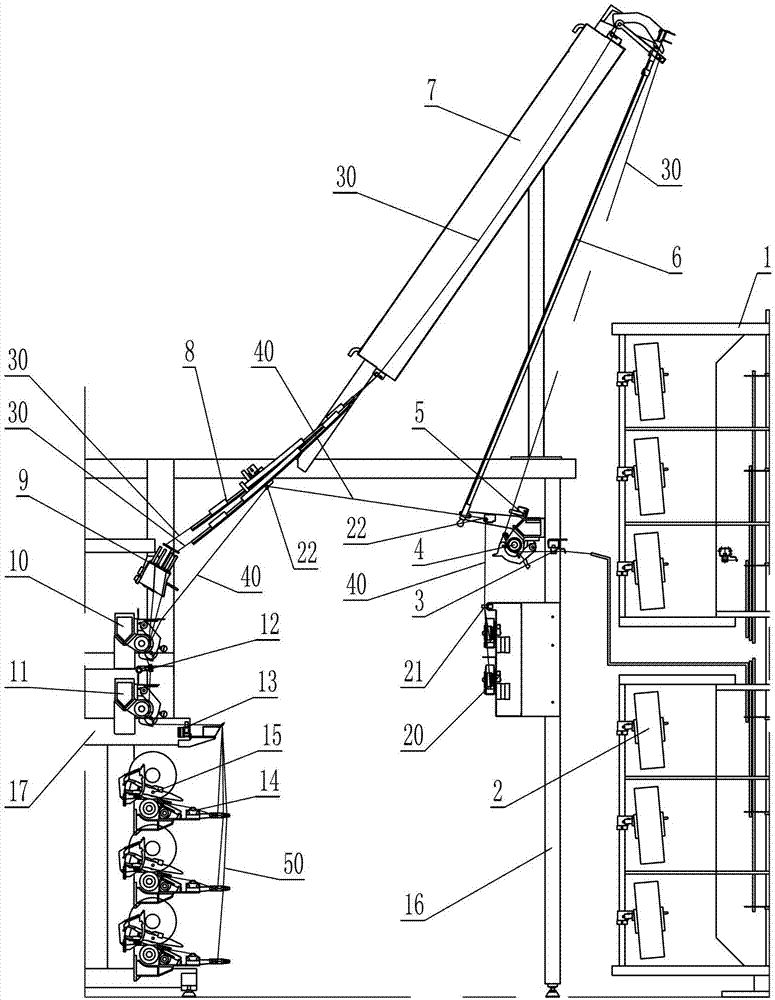

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0021] See eg figure 1 , is the transverse section arrangement diagram of the present invention. Because the whole device of the present invention is transversely symmetrical to the center, half of the transverse section is expressed in the diagram. The present invention includes two major branches as a whole, one is a false twist branch of two strands of nylon yarn passing through nylon yarn 30, and the other is a delivery branch of spandex yarn 40. After false twisting, the two strands of nylon yarn 30 pass through the network nozzle 12 together with the spandex yarn 40 for empty wrapping, and the final stroke is empty wrapping yarn 50 . A detailed description is given below.

[0022] Two strands of nylon yarn 30, in the present embodiment, after the nylon pre-oriented raw yarn (POY) is unwound from the silk cake 2 of the rotating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com