Porous silica gel used as liquid chromatography stationary phase material and preparation method thereof

A technology of porous silica gel and liquid chromatography, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of backward preparation methods and poor packing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

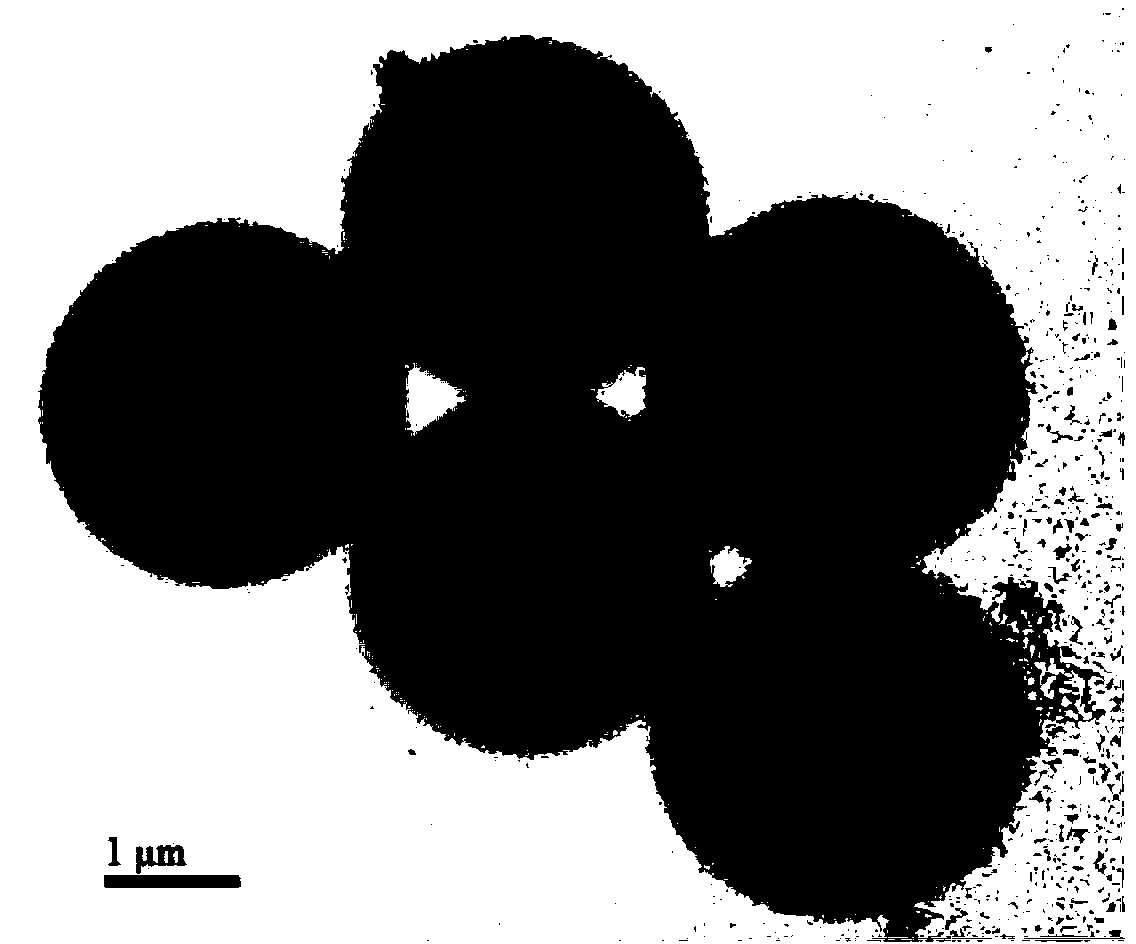

[0027] Dissolve 2g of PVP in a mixed solvent consisting of ethanol (60g) and water (8g), put it into a 250ml four-necked flask equipped with a thermometer, agitator and condenser, pass nitrogen protection, and pre-disperse at 70℃ for 30min , Then add monomer St (30g) and initiator AIBN (0.3g), react at 70℃ for 12h. Centrifuge the resulting product in a 10000r / s ultracentrifuge for 10 minutes. Wash the precipitate with 95% ethanol, then settle again to remove the supernatant. The above operations are repeated twice and then dried at room temperature to a milky white polystyrene powder Store at low temperature.

[0028] After dissolving 2g of PEI in water to make a 2% aqueous solution, add 1g of PS sample and magnetically stir for 6 hours.

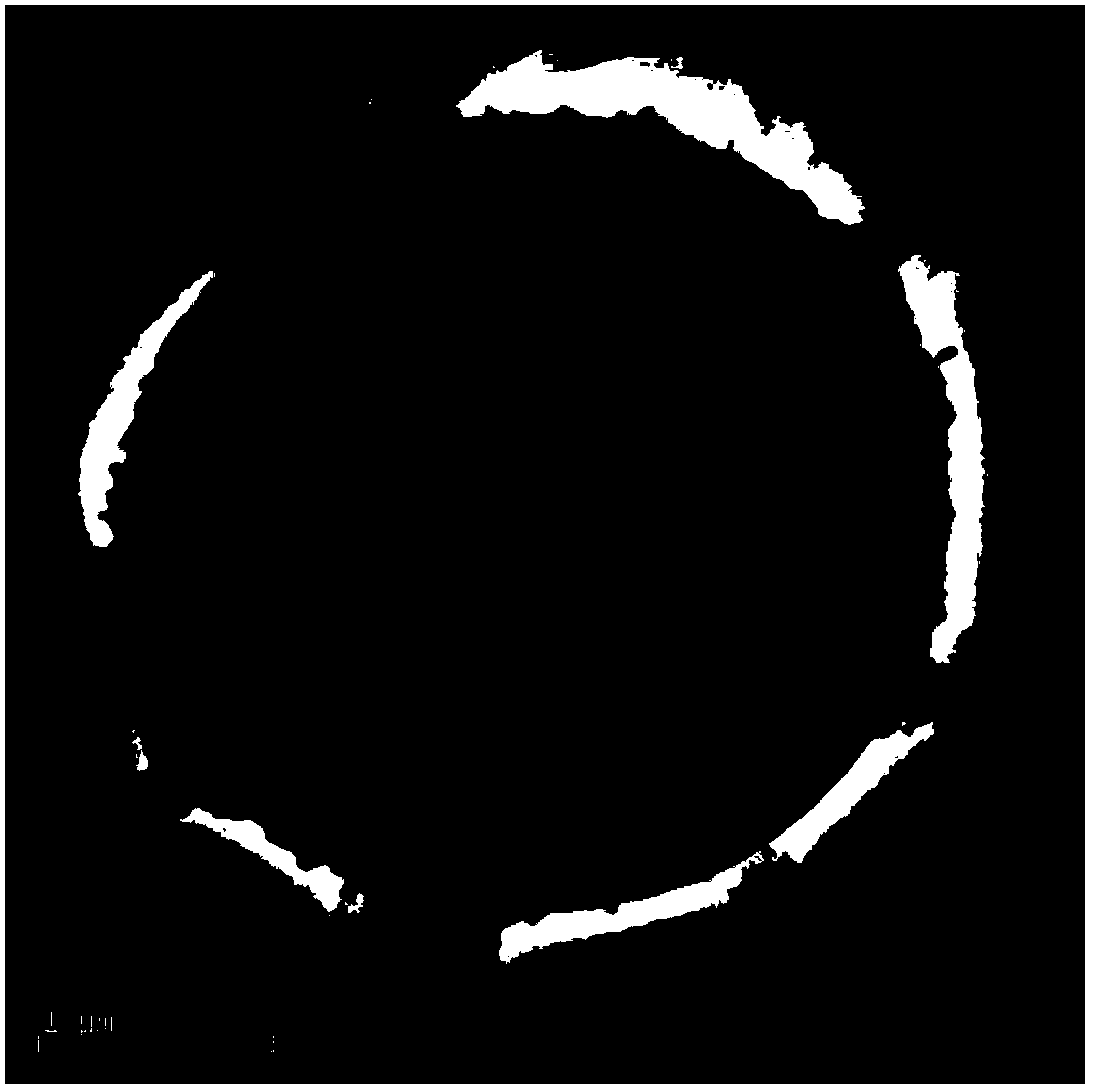

[0029] Add 20g of ethyl silicate, 6g of nitric acid, and 14g of distilled water into a 250ml beaker, and stir evenly until no layering occurs. Add 18.8g VTMS, continue to stir, when it becomes a sol, add 0.4g of PSPEI (ie polystyrene wrapped wi...

Embodiment 2

[0032] The preparation steps of the polystyrene microspheres and the encapsulated PEI in this embodiment are the same as those in the first embodiment. The difference is: add 10g of ethyl silicate, 3g of nitric acid, and 7g of distilled water into a 250ml beaker, and stir evenly until no layering occurs. Add 9.4g VTMS, continue stirring, when it becomes a sol, add 0.4g PS-PEI, continue stirring until it becomes a gel, stop stirring, and obtain a sandy polystyrene / polysiloxane gel composite.

[0033] Soak the polystyrene / polysiloxane gel composite obtained in the previous step with dimethylformamide for 10 minutes, put it in the reaction kettle and put it in the oven, set the temperature to 120℃, and the time to 4 hour. After the sample was taken out, it was put into a beaker, dissolved in DMF and continuously stirred, and repeatedly filtered with a water pump to finally obtain a white porous polysiloxane.

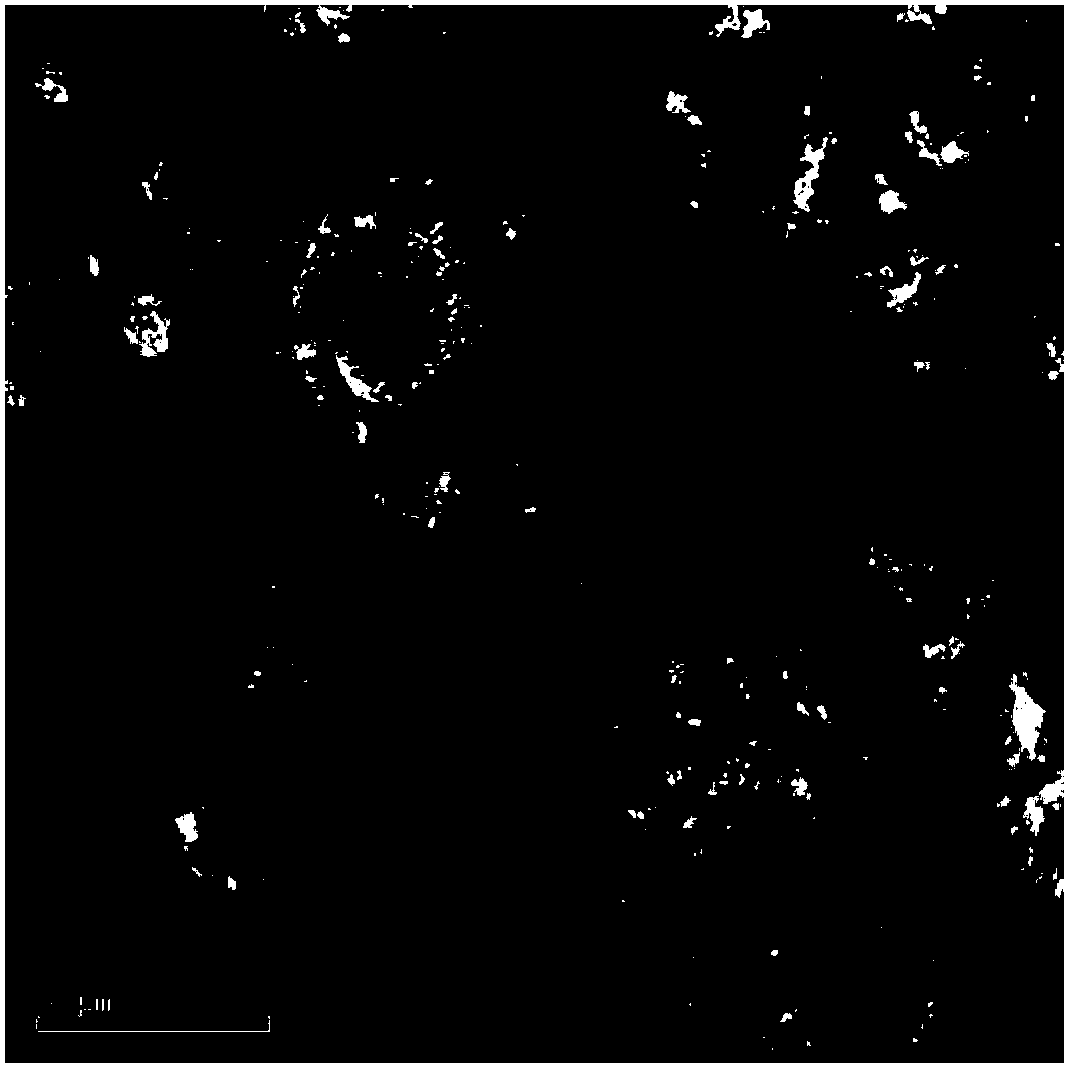

Embodiment 3

[0035] The preparation steps of the polystyrene microspheres and the encapsulated PEI in this embodiment are the same as those in the first embodiment. The difference is: add 5g ethyl silicate, 1.5g nitric acid, and 3.5g distilled water into a 250ml beaker, and stir evenly until no layering occurs. Add 4.7g VTMS, continue stirring, add 0.4g PS-PEI when it becomes a sol, continue stirring until it becomes a gel, stop stirring, and obtain a sandy polystyrene / polysiloxane gel composite.

[0036] Soak the polystyrene / polysiloxane gel composite obtained in the previous step with dimethylformamide for 15 minutes, put it in the reaction kettle and put it in the oven, set the temperature to 150°C, and the time to 4 hour. After the sample was taken out, it was put into a beaker, dissolved in DMF and continuously stirred, and repeatedly filtered with a water pump to finally obtain a white porous polysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com