Calculation Method of Machining Parameters of Non-Zero Indexing Bevel Synthetic Displacement Bevel Gear

A technology of shifting bevel gears and calculation methods, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of cumbersome calculations, improve calculation speed and accuracy, and reduce repeated calculations The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

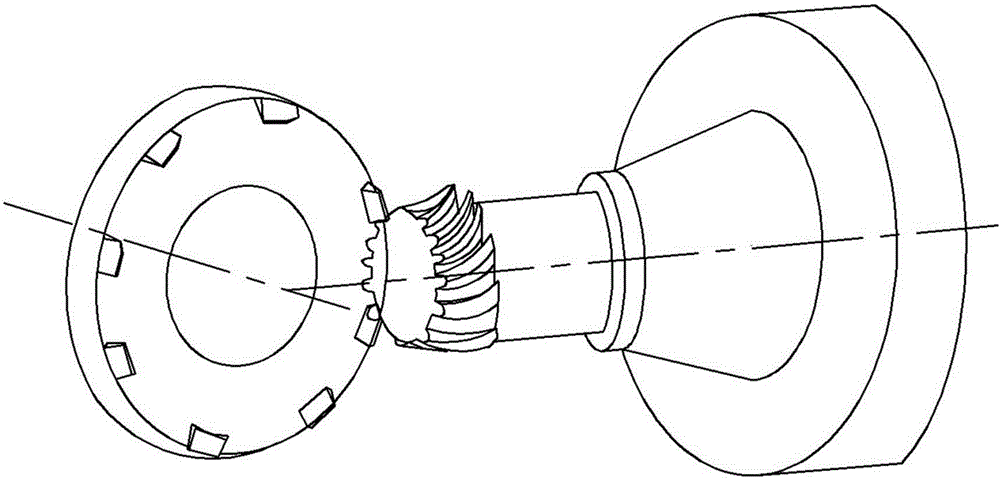

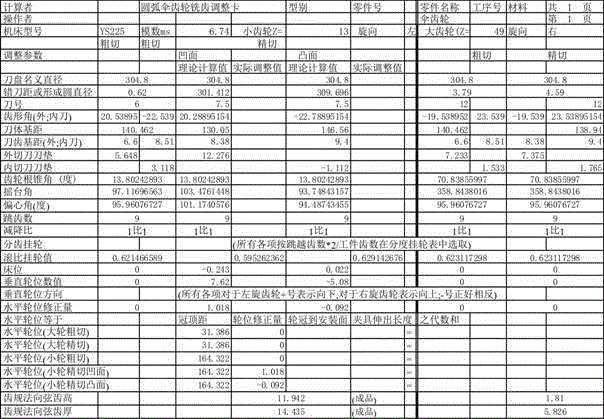

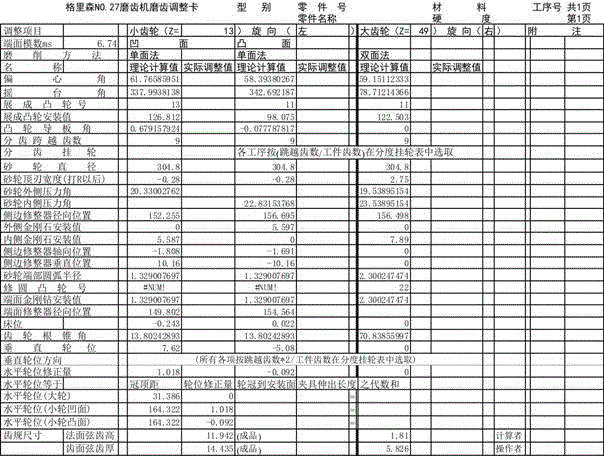

[0034] As shown in Figure 1, the processing of the new non-zero indexing bevel comprehensive displacement bevel gear can be processed by existing gear processing equipment, such as ordinary gear milling machines and gear grinding machines. Because the design feature of this transmission is that under the condition that the shaft angle Σ is constant, the sum of the comprehensive displacement coefficient composed of the radial displacement coefficient and the tangential displacement coefficient is not zero. That is to say, the sum of the circular tooth thicknesses of the large and small gears is not equal to the pitch π*m. Therefore, the process pitch cone must be taken on the meshing pitch cone when the transmission pair is meshed during calculation. The parameters input during the calculation must be the parameters on the pitch cone and pitch circle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com