Stapler with bookbinding baffle

A technology of stapler and baffle, which is applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc., and can solve the problem of short binding baffle, stapler without binding baffle, difficult position limitation and distance reference And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

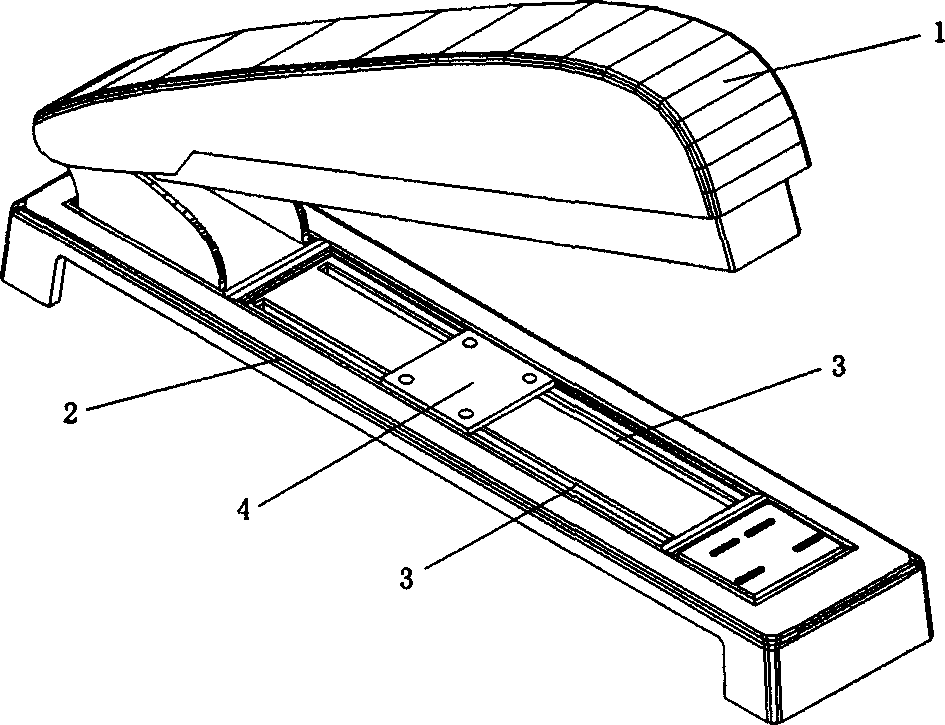

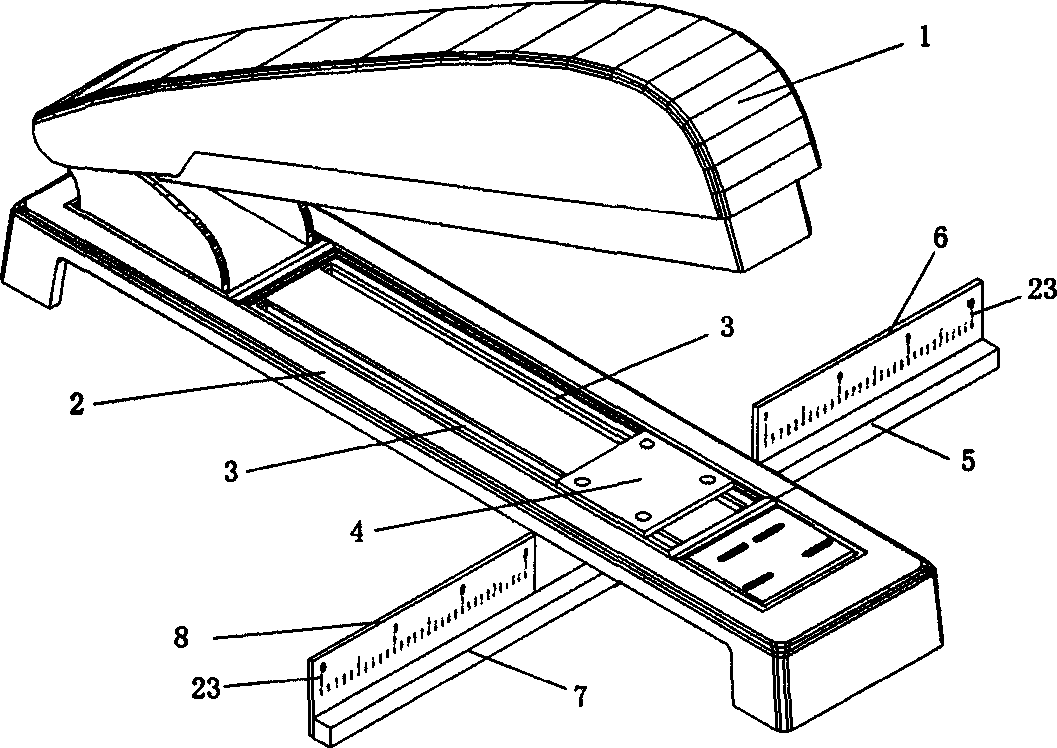

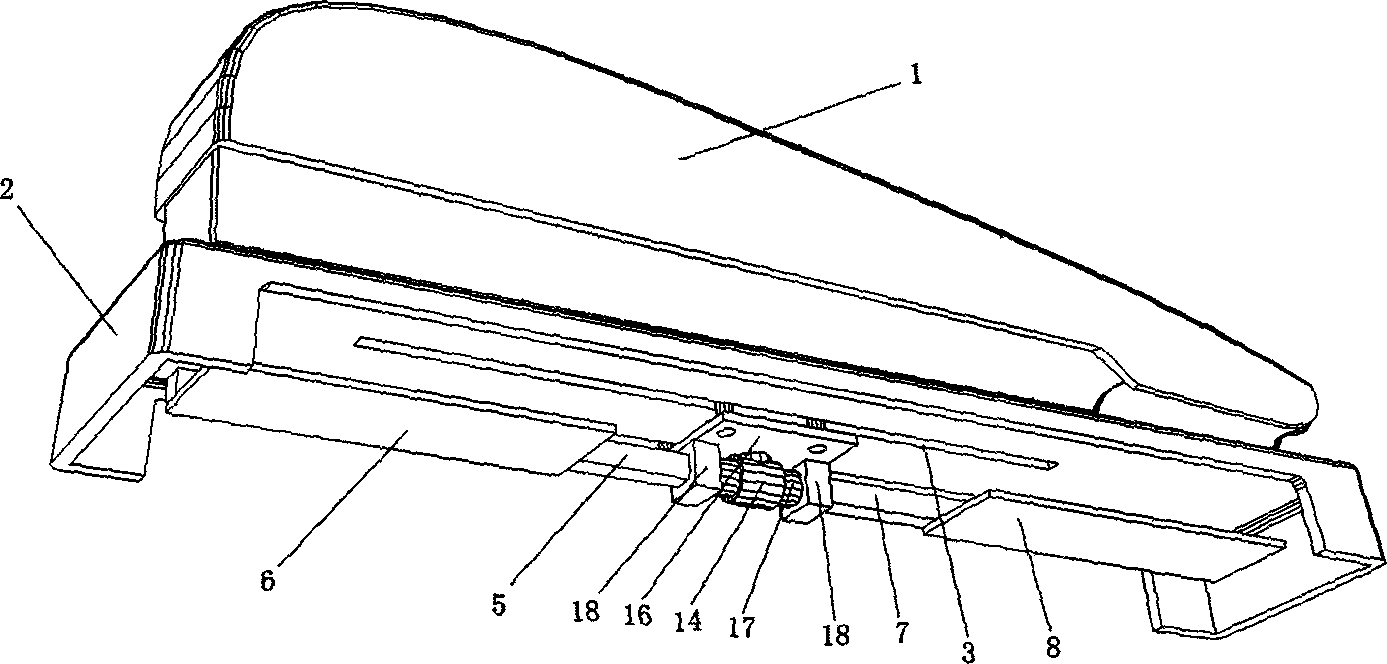

[0014] Control attached figure 1 , 2 , 3, 4, attached figure 1 It is a perspective view of the appearance of one of the embodiments of the present invention, with figure 2 yes figure 1 Three-dimensional diagram of the use status, attached image 3 yes figure 1 Perspective view of the binding baffle in when it is rotated and stored at the bottom of the base Figure 4 yes figure 1 An exploded perspective view of the binding bezel in . The base 2 of the stapler in the figure is in the shape of a long bench, that is, the base supporting parts are located at the two ends of the long sides of the base, and the middle part of the long sides of the base is upwardly concaved into a long-shaped gap, and the middle part of the upper surface of the base 2 is concave downward, and the bottom part A slit parallel to the central axis of the base is cut on the left and right sides of the recess to form a guide rail 3, and the slider 4 is slidably connected to the base 2 through the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com