A kind of hexagonal boron nitride-ytterbium silicon oxide-silicon dioxide composite material and preparation method

A technology of hexagonal boron nitride and silicon dioxide, which is applied in the field of hexagonal boron nitride-ytterbium silicon oxide-silicon dioxide composite materials and its preparation, can solve the problems of low density and achieve low cost, high strength, good The effect of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Hexagonal boron nitride phase (h-BN) 95%-ytterbium silicon oxide (Yb 2 Si 2 o 7 ) 1% - silicon dioxide (SiO 2 )4%

[0031] 37.55 grams of 0.5 micron hexagonal boron nitride powder, 0.71 grams of 400-order ytterbium trioxide powder and 1.74 grams of 400-order silicon dioxide powder (in design (h-BN)-ytterbium silicon oxide (Yb 2 Si 2 o 7 )-Silicon dioxide (SiO 2 ) composite material, the content of silicon dioxide in the raw material is excessive, and part of it is used to combine with ytterbium trioxide (Yb 2 o 3 ) in situ reaction to generate ytterbium silicon oxide (Yb 2 Si 2 o 7 ), another part generates amorphous silicon dioxide (SiO 2 ) phase, which is beneficial to suppress the Yb in the raw material 2 o 3 React with BN, so the content of silicon dioxide is more, the following examples are the same), put into the silicon nitride tank and ball mill for 24 hours, dry, sieve through 80 mesh sieves, then pack into graphite mold and cool Compre...

Embodiment 2

[0032] Example 2: Hexagonal boron nitride phase (h-BN) 67%-ytterbium silicon oxide (Yb 2 Si 2 o 7 )5% - silicon dioxide (SiO 2 )28%

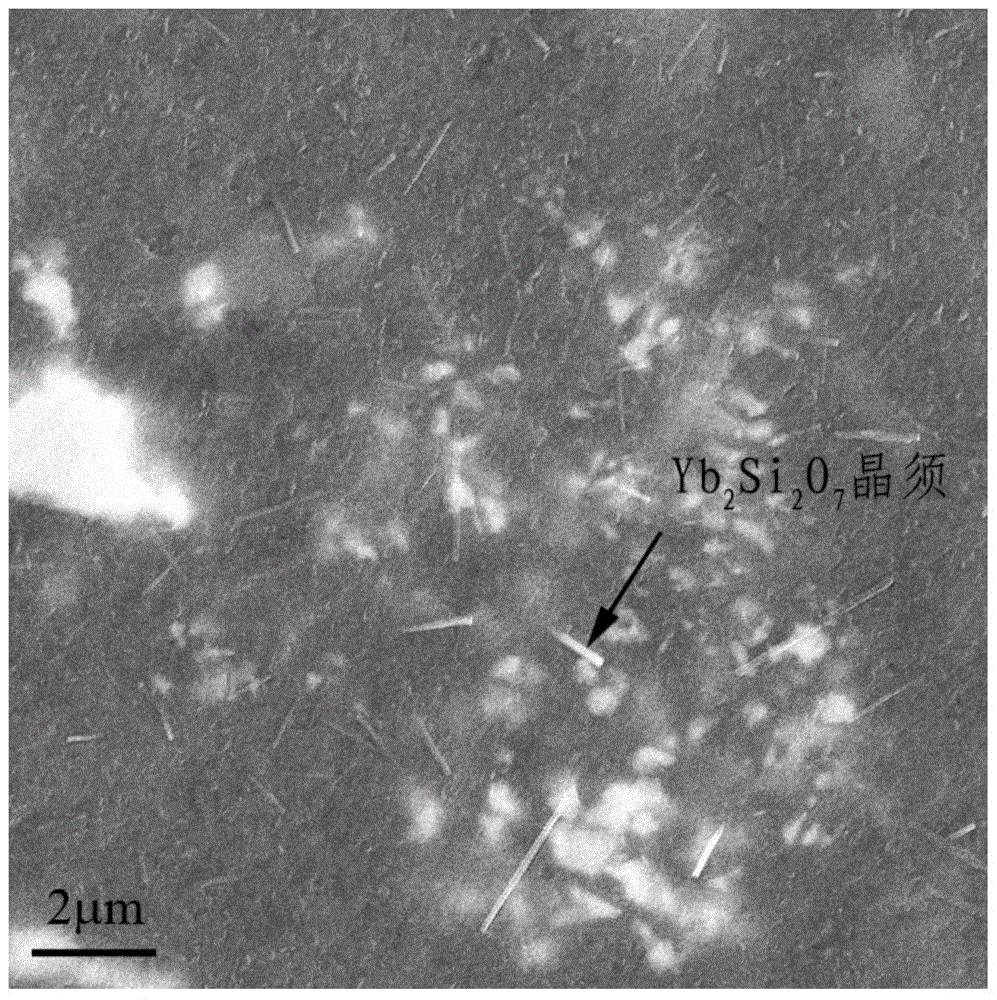

[0033] Put 24.89 grams of 1 micron hexagonal boron nitride powder, 3.86 grams of 300-mesh diytterbium trioxide powder and 11.26 grams of 300-mesh silicon dioxide powder into a silicon nitride tank for ball milling for 12 hours, dry, and pass through an 80-mesh sieve , and then put it into a graphite mold for cold pressing, with an applied pressure of 15MPa, and then put it into a hot-press furnace for hot-pressing sintering: the heating rate is 10°C / min, after heating to 1800°C, the sintering pressure is 30MPa, and the temperature is kept for 2 hours. The whole sintering process is carried out under the protection of argon, and the obtained reaction products are analyzed by X-ray diffraction as h-BN, Yb 2 Si 2 o 7 and SiO 2 Three-phase, where SiO 2 The phase is amorphous. Part of Yb was found by microstructural observation 2 Si 2 o 7...

Embodiment 3

[0034] Example 3: Hexagonal boron nitride phase (h-BN) 67%-ytterbium silicon oxide (Yb 2 Si 2 o 7 ) 20% - silicon dioxide (SiO 2 )13%

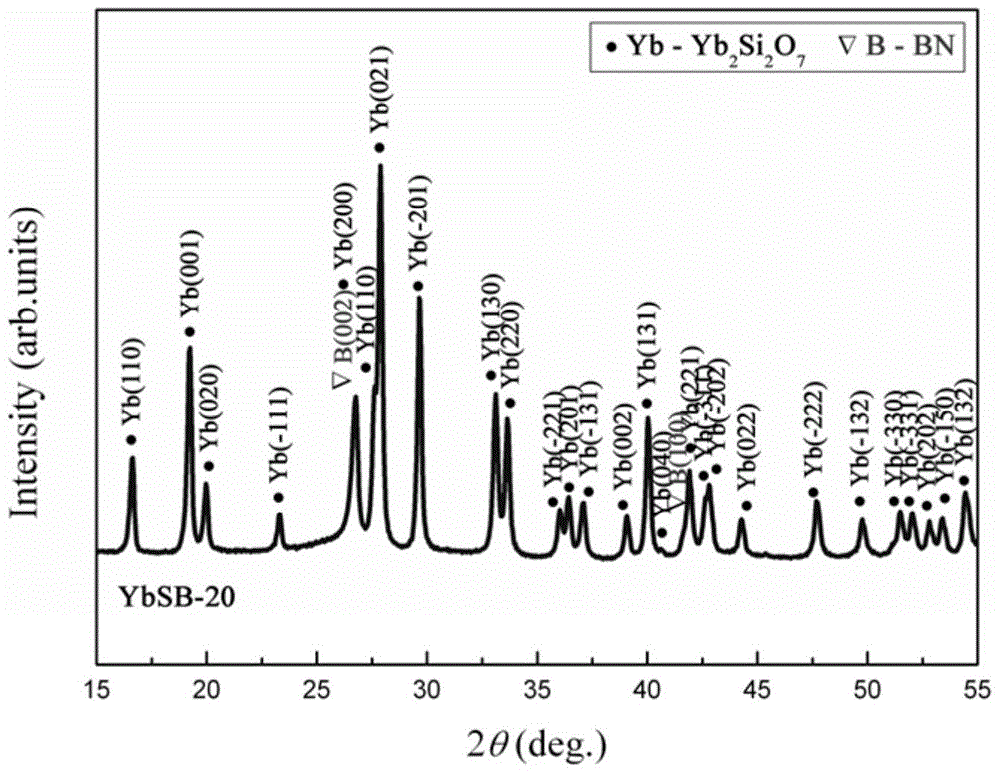

[0035] Put 20.03 grams of 5-micron hexagonal boron nitride powder, 12.42 grams of 200-mesh ytterbium trioxide powder and 7.55 grams of 200-mesh silicon dioxide powder into a silicon nitride tank for ball milling for 8 hours, dry, and sieve through an 80-mesh sieve , and then put it into a graphite mold for cold pressing, and the applied pressure is 10MPa, and then put it into a hot-press furnace for hot-press sintering. The heating rate is 20°C / min, and the temperature is heated to 1700°C for 1 hour. The whole sintering process is carried out under the protection of argon, and the obtained reaction products are analyzed by X-ray diffraction as h-BN, Yb 2 Si 2 o 7 and SiO 2 Three-phase, where SiO 2 The phase is amorphous, such as figure 2 shown. In this embodiment, the density of the composite material is 3.0 g·cm -3 , the Young's ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com