Booster flow guide for fluidized dryer

A technology of boiling dryer and diversion device, which is applied in the direction of drying gas arrangement, dryer, drying solid materials, etc., can solve the problem of material not blowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or uses. The specific embodiments of the pressurization and flow guiding device used in the boiling dryer of the present invention will be further described below with reference to the accompanying drawings.

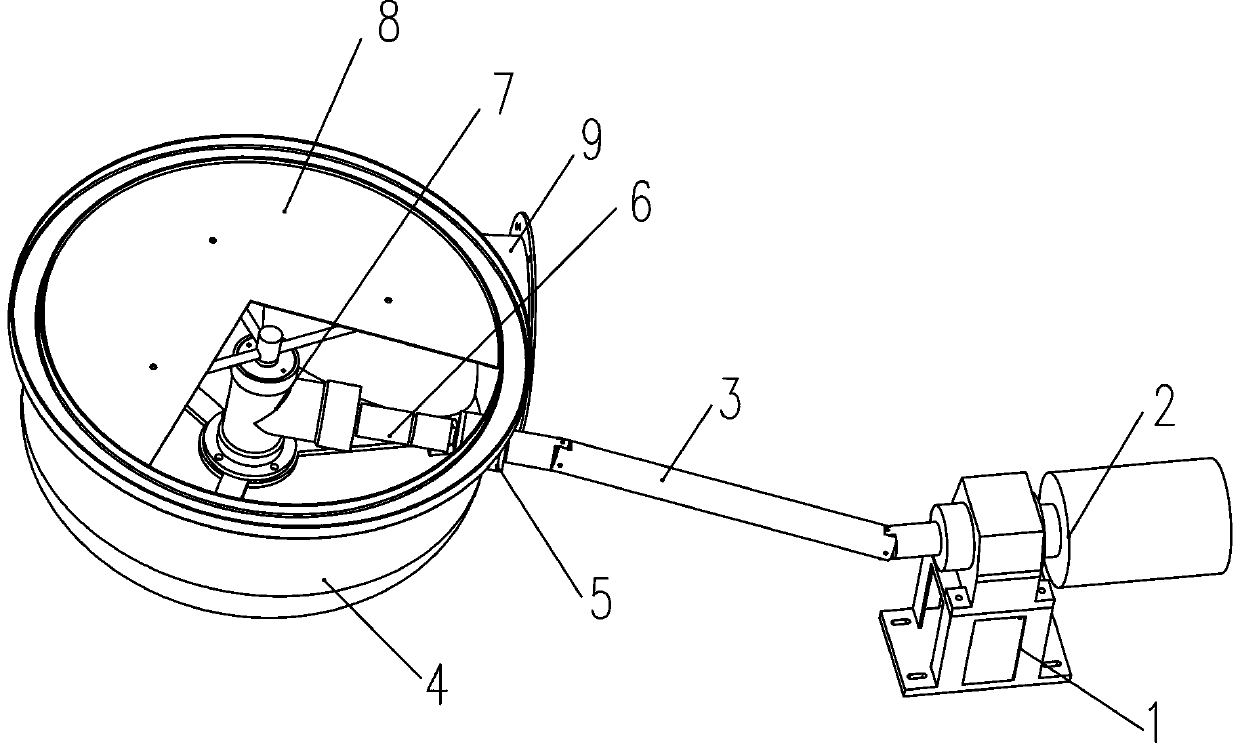

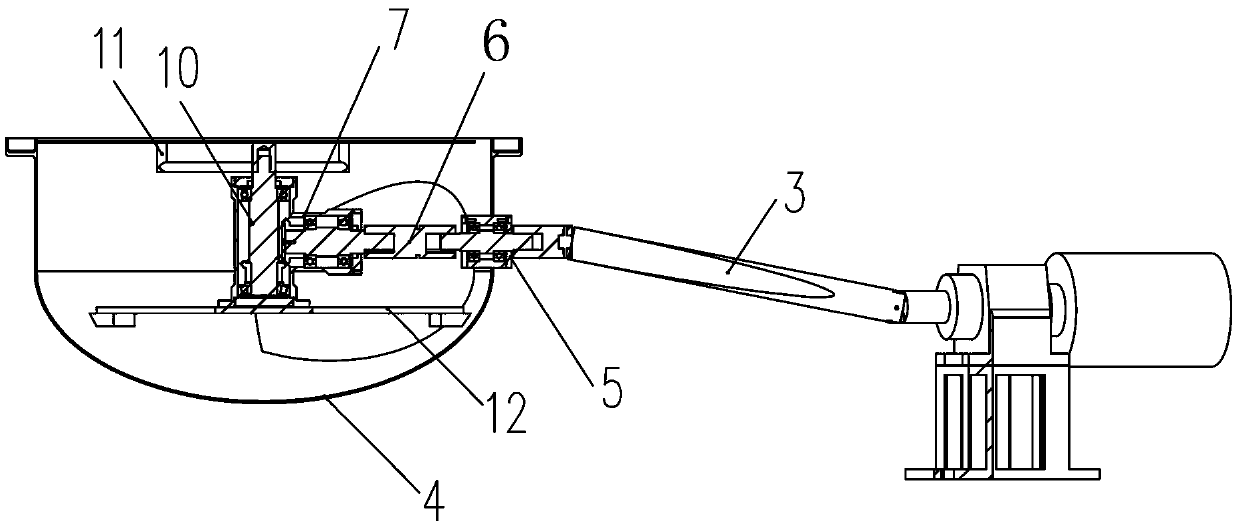

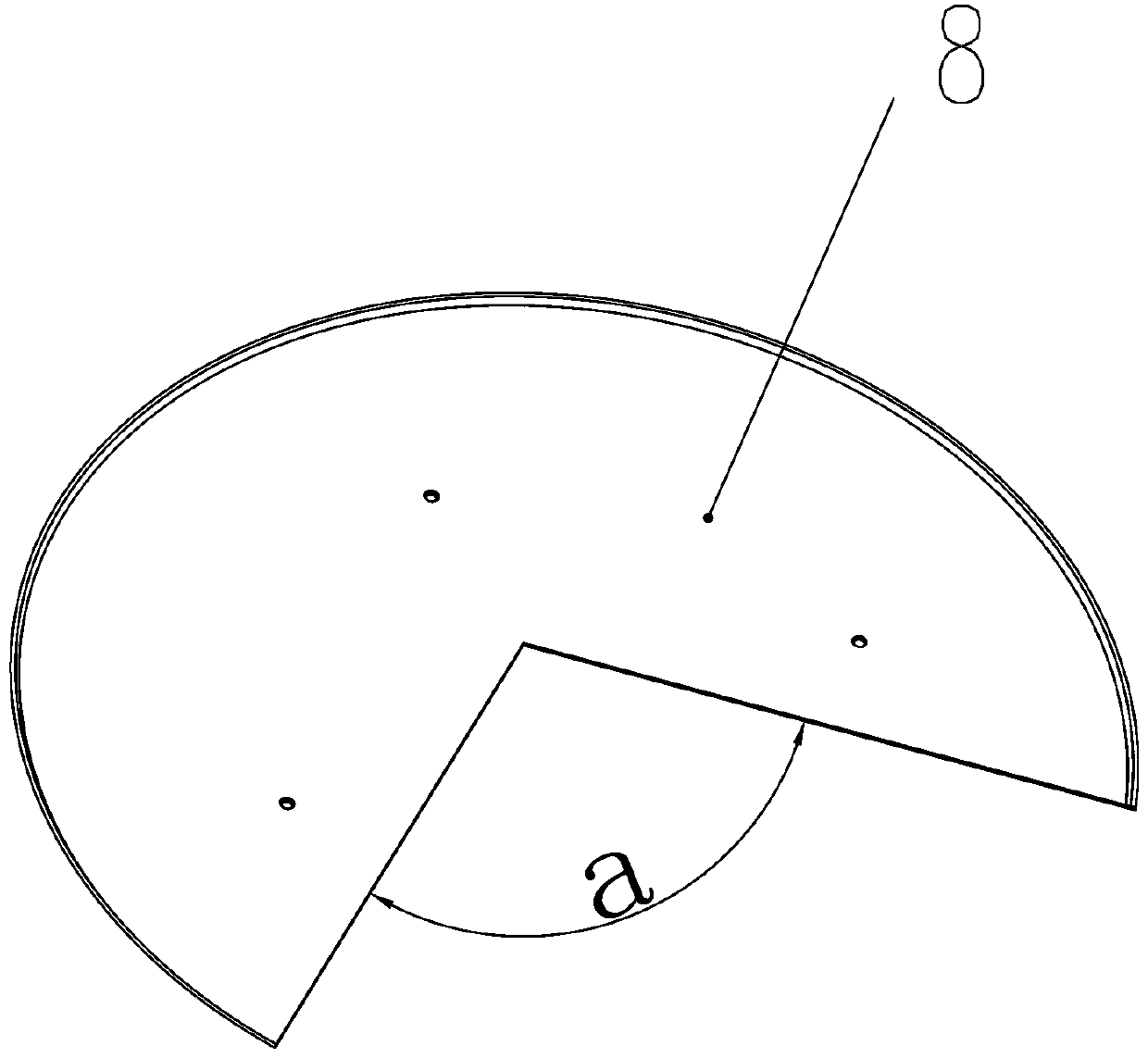

[0027] like figure 1 , figure 2 As shown, a schematic structural diagram of a preferred embodiment of the pressure boosting and guiding device for a boiling dryer according to the present invention. A pressurization and diversion device for a boiling dryer of the present invention includes a pot body 4, an air inlet 9 is connected to the side wall of the pot body 4, and a V-shaped paddle 8 is provided on the top of the pot body 4. The V-shaped blade 8 is fixed on the rotating shaft 10 . When working, the air inlet 9 enters the air, starts the motor 2, and the motor 2 drives the rotating shaft 10 to rotate, thereby driving the V-shaped paddle 8 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com