Novel ink scraper

A new type of scraper technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as unstable ink liquid level, incomplete patterns or characters, incomplete ink staining of rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

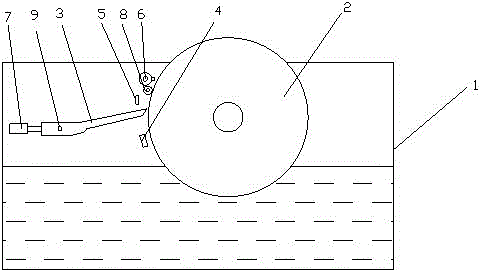

[0013] The present invention as Figure 1-2 As shown, it includes an ink tray 1, a roller 2 and a scraper 3. The ink tray is used to hold ink, and the lower part of the roller is immersed in the ink of the ink tray. The scraper is arranged on the ink tray and located at one side of the roller;

[0014] Also includes a heater 4, a controller, an imaging mechanism 5, a pressure roller 8 and an inkjet mechanism 6,

[0015] The two ends of the heater 4 are fixed on the side wall of the ink tray and are positioned under the scraper. When the scraper scrapes off the protruding ink, the protruding ink will fall onto the heater to act as a buffer so that the ink level smooth;

[0016] The imaging mechanism is arranged above the doctor blade and is used for the imaging of the roller, the imaging mechanism 5 is connected to the controller, and the pressure roller 8 is located between the imaging mechanism and the inkjet mechanism and is used for bonding the roller, The pressure rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com