In-mold punching mechanism and injection molding mold

An injection molding and moving template technology, applied in the field of injection molding molds and in-mold punching mechanisms, can solve the problems of increased processes, high mold development costs, inaccurate tool positioning, etc., to reduce mechanism development costs, facilitate design and implementation, The effect of simplifying the institutional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

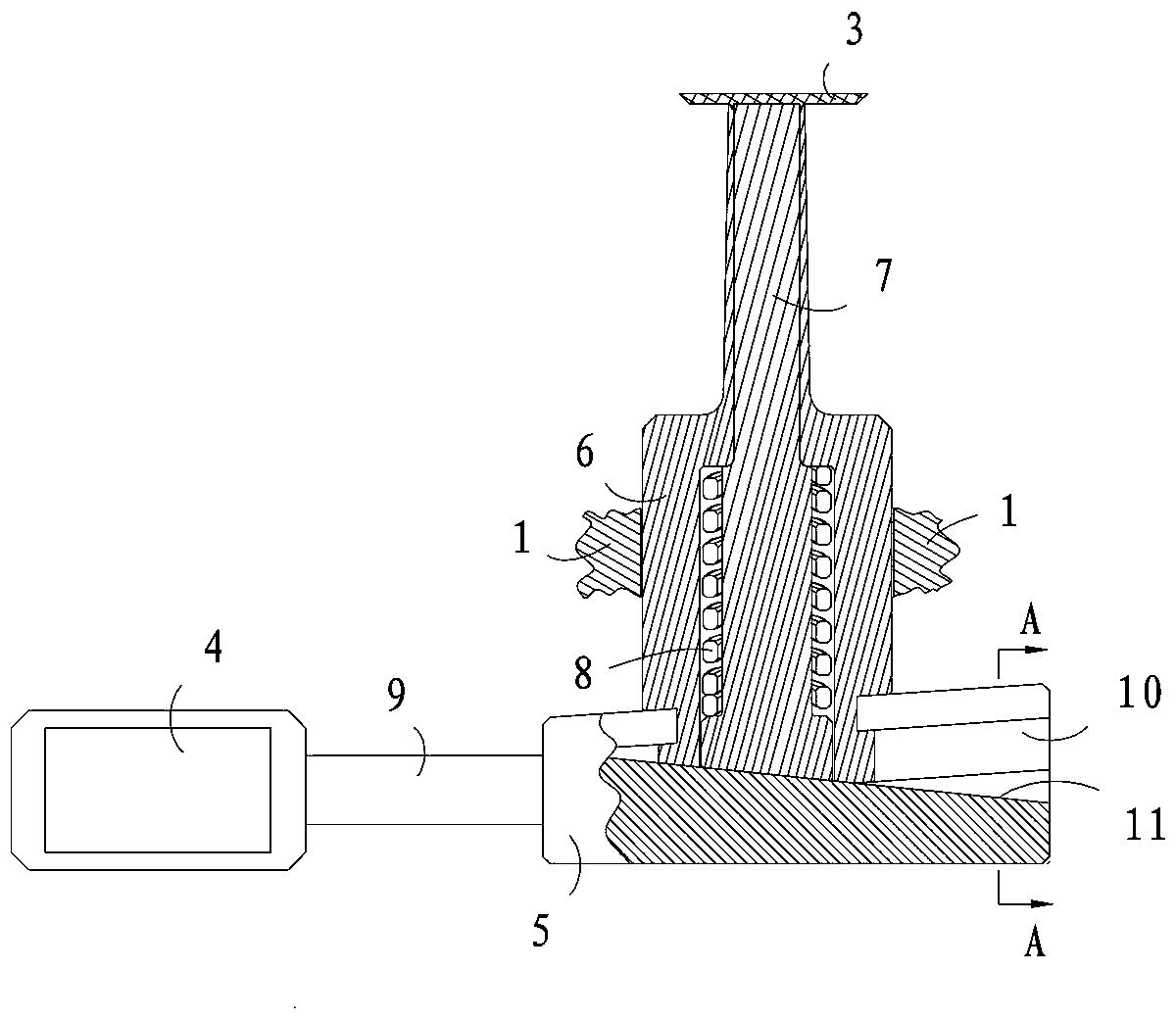

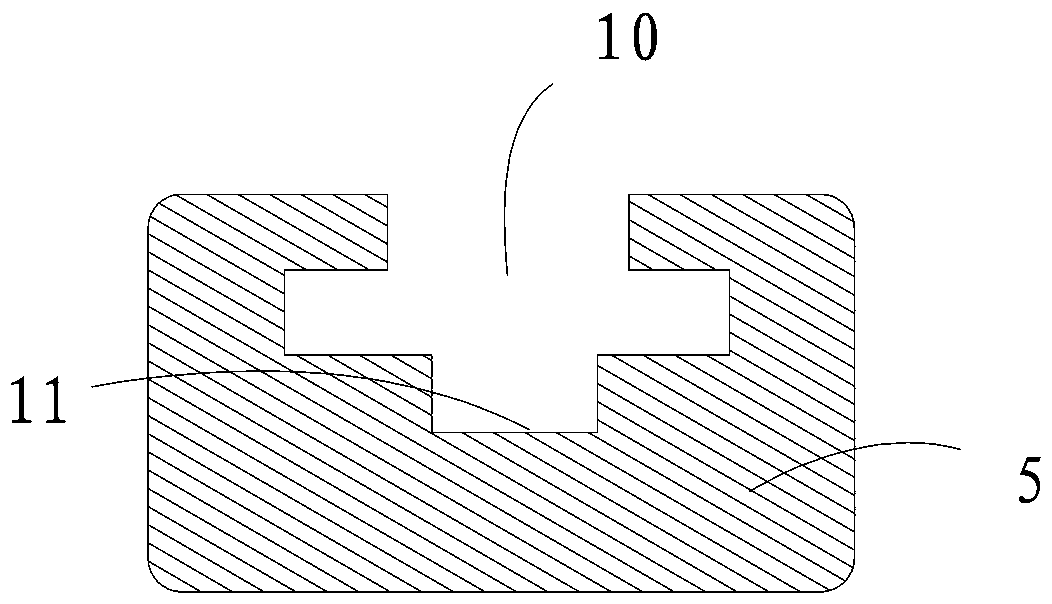

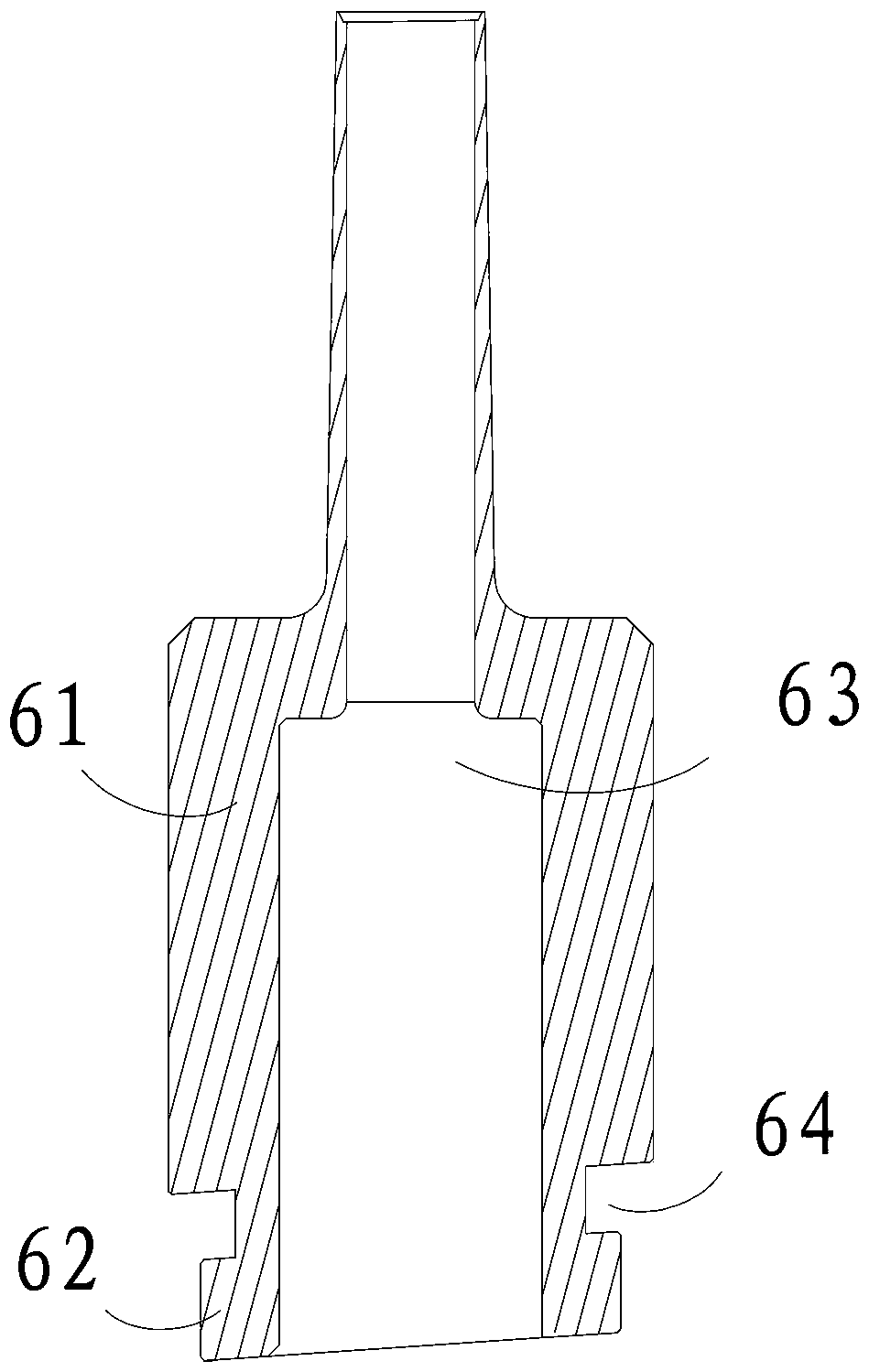

[0032] The invention relates to an in-mold punching mechanism, which is accommodated in a fixed plate or a movable plate that can be fastened together for injection molding of parts. The hole punching knife for punching the parts, and the ejector rod that is movable in the hole punching knife, also includes the transmission connection with the hole punching knife and the ejector rod, so as to drive the hole punching knife and the ejector rod to have Synchronized relative motion of drive components.

[0033] The in-mold punching mechanism of the present invention, by setting it in the movable template or the fixed template, and corresponding to the opening position on the workpiece, can punch on the workpiece during the injection molding process of the workpiece. If the hole is formed, the drive assembly can be used to drive the hole punching knife to punch the hole when the injection molding of the part is completed and the shape is not cooled. The synchronous relative moveme...

Embodiment 2

[0043] This embodiment relates to an injection molding mold, which includes a fixed template and a movable template that can be interlocked for injection molding of parts, on the movable template or the fixed template or on both the movable template and the fixed template An in-mold punching mechanism as described in Embodiment 1 is provided. By setting the in-mold punching mechanism, the workpiece can be punched when the injection molding of the workpiece is completed and the mold is not cooled and shaped, which can avoid the trouble of punching after the injection molding is completed. At the same time, the setting of the punching mechanism in the mold does not need to set the structural hole positions in the mold cavity, so as to avoid the problem of welding lines due to the setting of the structural hole positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com