Loading device and method for horizontal tension test for quasi-rectangular shield segment

A technology of shield segment and loading device, which is applied in the field of tunnel shield, can solve the problem of less lining test and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

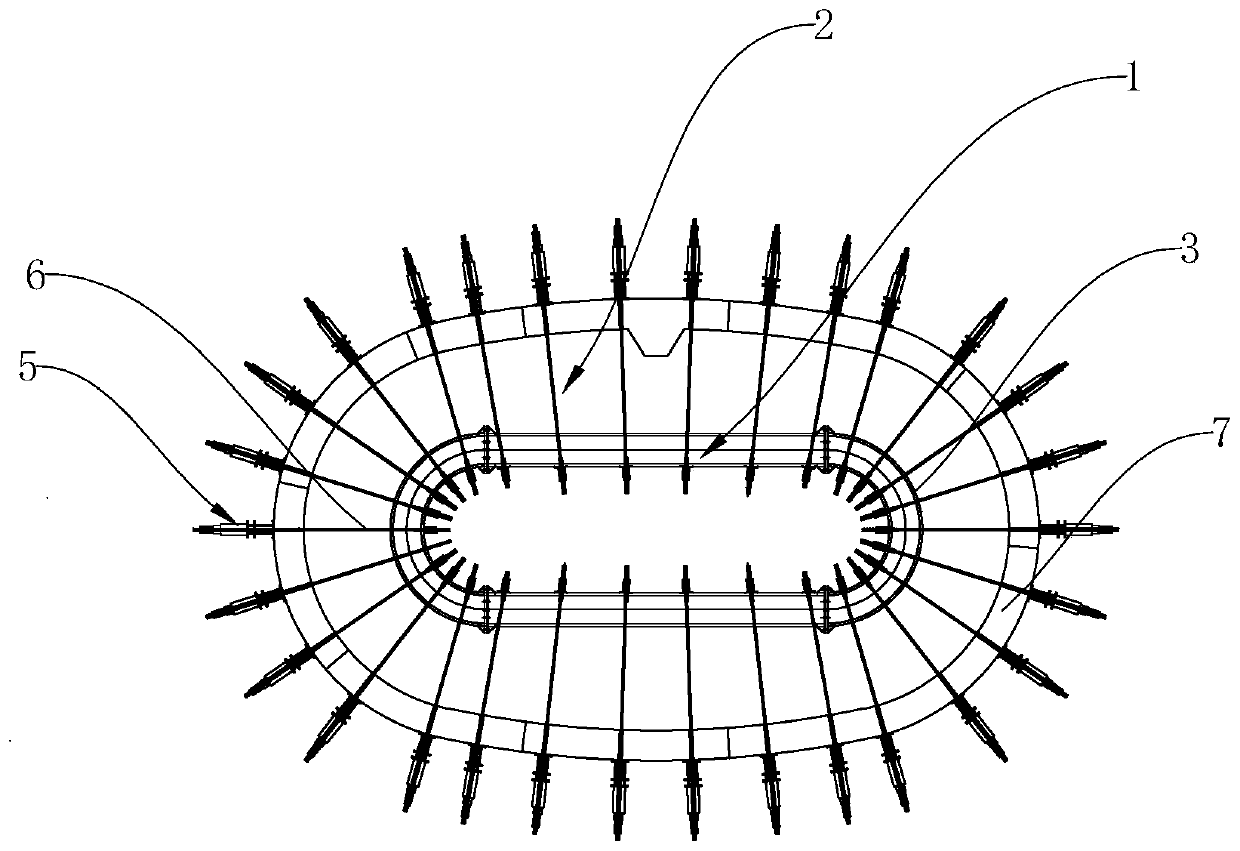

[0028] Embodiment 1: As shown in the figure, a horizontal tension test loading device for a rectangular shield segment 7 includes

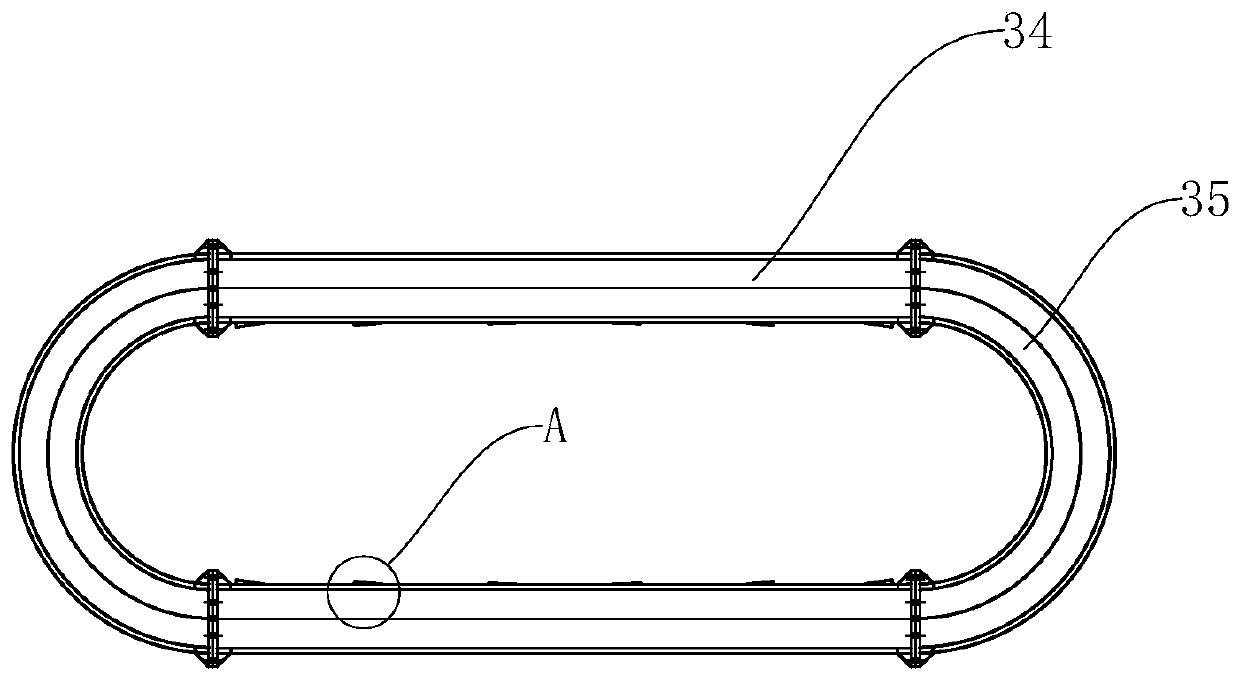

[0029] The central reaction force device 1 is composed of a reaction force frame 3 and a first adjustment support 4, the reaction force frame 3 is located on the inner side of the shield segment 7, and the first adjustment support 4 is connected to the bottom of the reaction force frame 3;

[0030] The loading device 2 is composed of a plurality of loading mechanisms 5 acting on the shield segment 7 and a plurality of horizontally distributed force transmission members 6. The plurality of loading mechanisms 5 are distributed at intervals and are surrounded by the shield segment 7. On the outside, one end of the force transmission member 6 is connected to the corresponding loading mechanism 5 , and the other end of the force transmission member 6 is connected to the reaction force frame 3 .

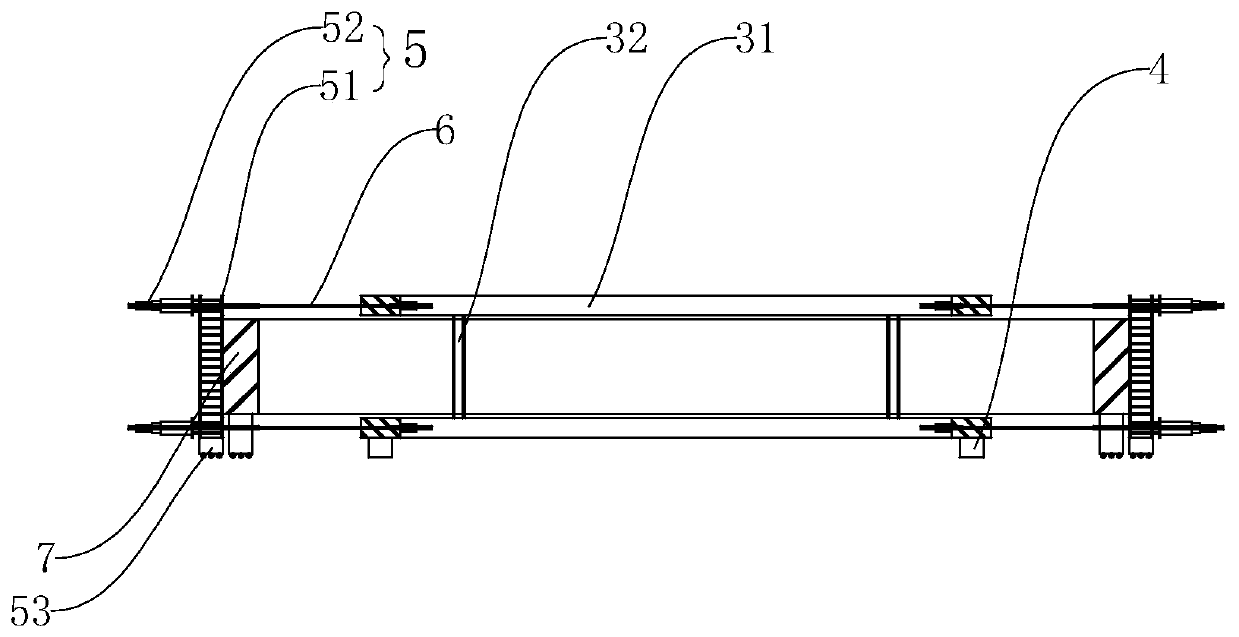

[0031] In this embodiment, each loading mechanism 5 incl...

Embodiment 2

[0040]Embodiment 2: As shown in the figure, a loading method using a horizontal tension test loading device for a similar rectangular shield segment comprises the following steps,

[0041] S1: place the reaction frame 3 on the first adjustment support 4;

[0042] S2: place the shield segment 7 on the periphery of the reaction frame 3, and install a support with steel balls on the bottom of the shield segment 7;

[0043] S3: arrange the second adjusting support 53 along the outer contour of the shield segment 7, place the loading beam 51 on the second adjusting support 53, and cling to the outer wall of the shield segment 7, and then fix the loading member 52 on the loading beam 51;

[0044] S4: Connect one end of the force transmission part 6 with the loading part 52, and fix the other end of the force transmission part 6 on the reaction force frame 3;

[0045] S5: After the installation is completed, the loading member 52 slowly applies a load until a preset requirement is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com