Method for manufacturing high-strength torsion beams controlled by stamping

A technology of stamping forming and manufacturing methods, which is applied in interconnection systems, vehicle parts, transportation and packaging, etc., can solve problems such as large deformation, reduced strength of torsion beams, and cracks in pipes, so as to reduce the risk of abnormal noise and improve Quality, the effect of avoiding excessive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

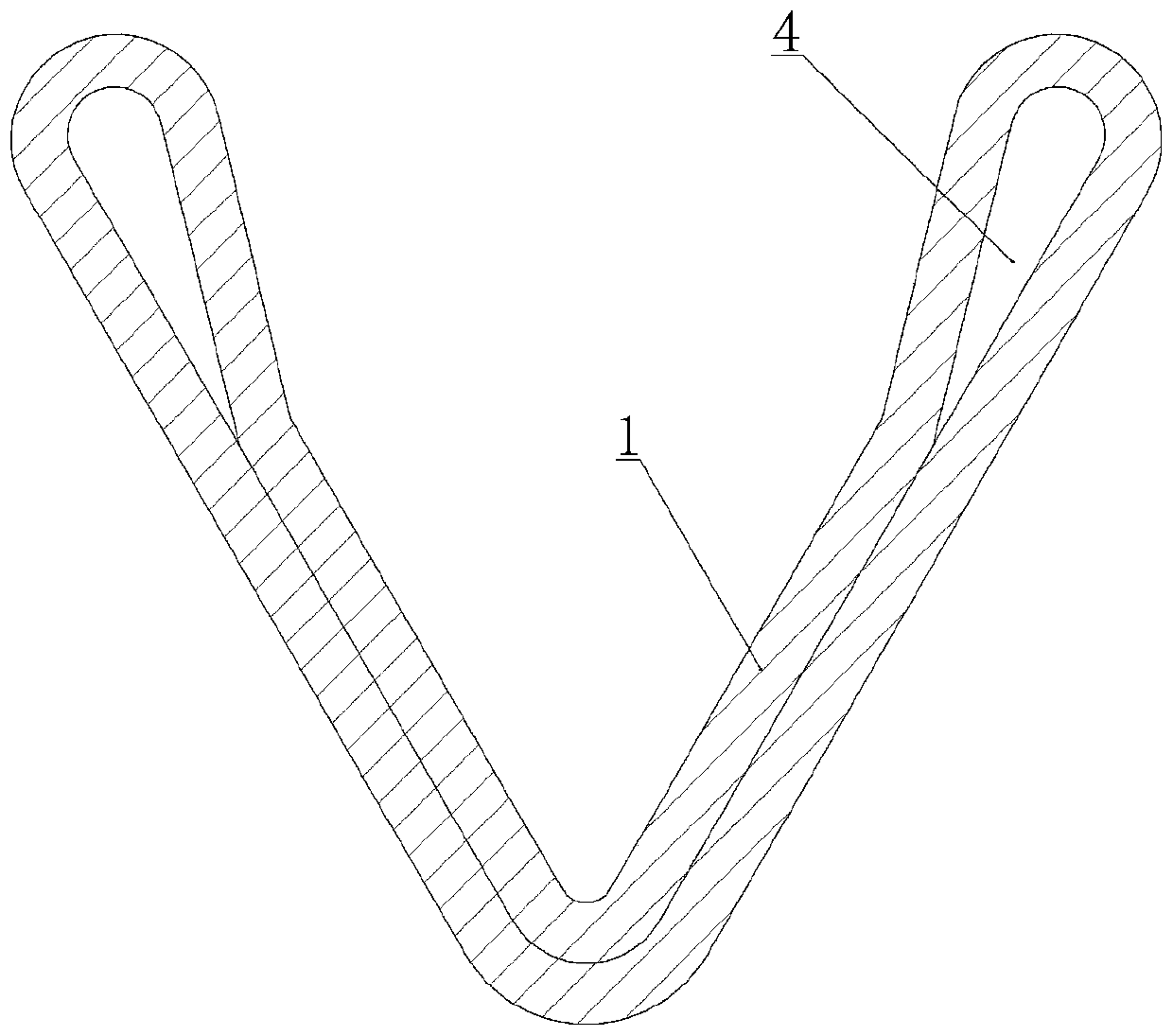

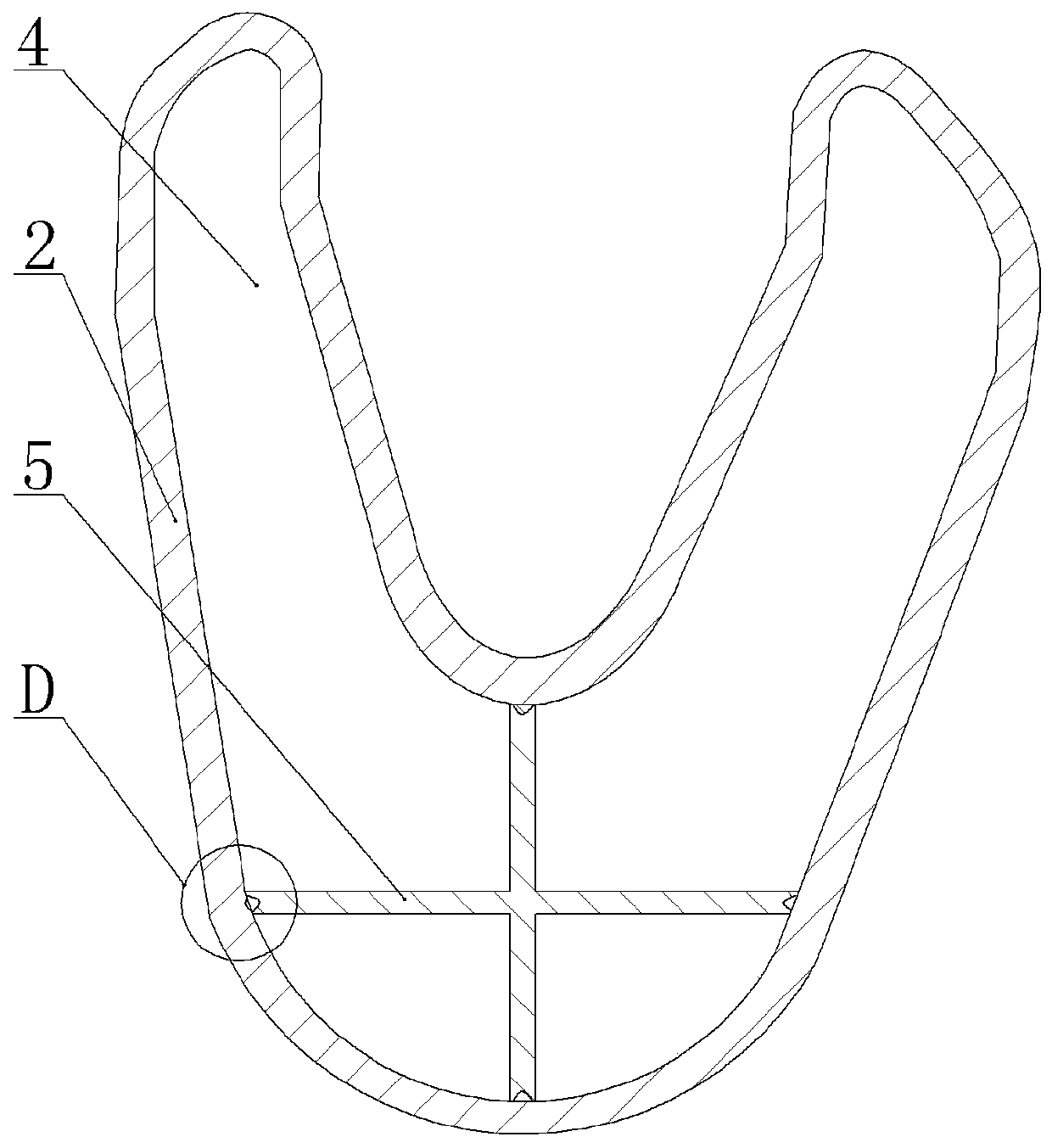

[0038] Regulates methods of manufacturing stamped and formed high-strength torsion beams, such as Image 6 As shown, the torsion beam is formed by stamping the pipe material 6, and four retaining rods coaxial with the pipe material 6 are inserted into the inner cavity of the pipe material 6 used to manufacture the high-strength torsion beam. The annular elastic sleeve 71 on the 7 and some support rods 72 between the elastic sleeve 71 and the central rod 7, the central rod 7 and the elastic sleeve 71 in this embodiment are all longer than the pipe 6, and the left end of the central rod 7 is a handle The holding end, when the central rod 7 is located in the pipe 6, the holding end is located outside the pipe 6. The elastic sleeve 71 is made of NBR, and the surface of the elastic sleeve 71 is smooth. The two ends of the support rod 72 are respectively hinged on the central rod 7 and the elastic sleeve 71 .

[0039] And when the center rod 7 is manually pushed to the right relati...

Embodiment 2

[0047] like Figure 8 As shown, on the basis of Embodiment 1, the right end of the elastic sleeve 71 in this embodiment is closed to prevent paraffin from entering the elastic sleeve 71 from the right end of the elastic sleeve 71, so when the elastic sleeve 71 slides in from the left end of the pipe material 6 from The right end of the pipe 6 feeds molten paraffin into the pipe 6 to improve work efficiency. In practice, in addition to the paraffin, the pipe 6 can also be filled with molding sand, steel shot with a diameter less than or equal to 1mm, or a combination of molding sand, steel shot and paraffin. Other than that, other operation steps in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com