Water borne dry lamination bonding agent with heat resistance improvement

A technology of adhesive and substrate layer, applied in the direction of adhesive, rosin adhesive, adhesive type, etc., can solve the problem that the adhesive cannot meet the packaging requirements of medium performance and high requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

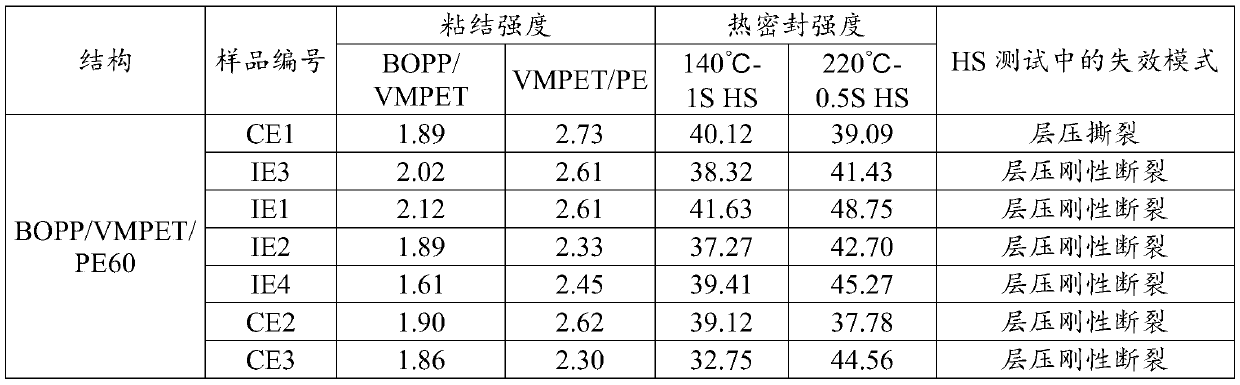

Examples

example

[0034] I. Raw materials

[0035] Films: The substrates used in the examples included biaxially oriented polypropylene film (BOPP, 18 μm thickness), vacuum metallized cast polyethylene terephthalate polyester film (VMPET, 12 μm thickness) film and polyethylene film (PE, thickness 60 μm), as commercially obtained from Guangdong Nan Cheng Company.

[0036] The ingredients used in the examples include those listed in Table 1 below.

[0037] Table 1: Components used in the examples

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com