Torsion adjusting mechanism and fireproof check valve

A technology of torque adjustment and adjustment plate, which is applied in safety valves, balance valves, valve devices, etc., can solve problems such as difficulty in exhausting smoke, easy opening of valve plates, backflow of outdoor smoke into the room, etc., and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

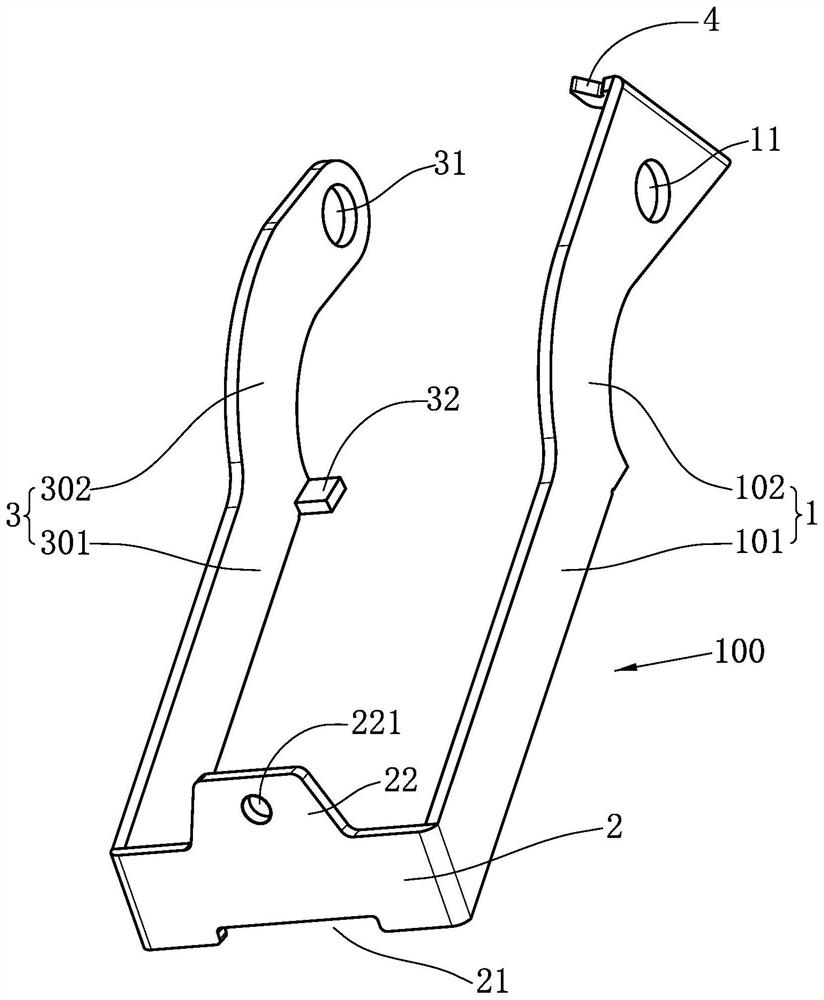

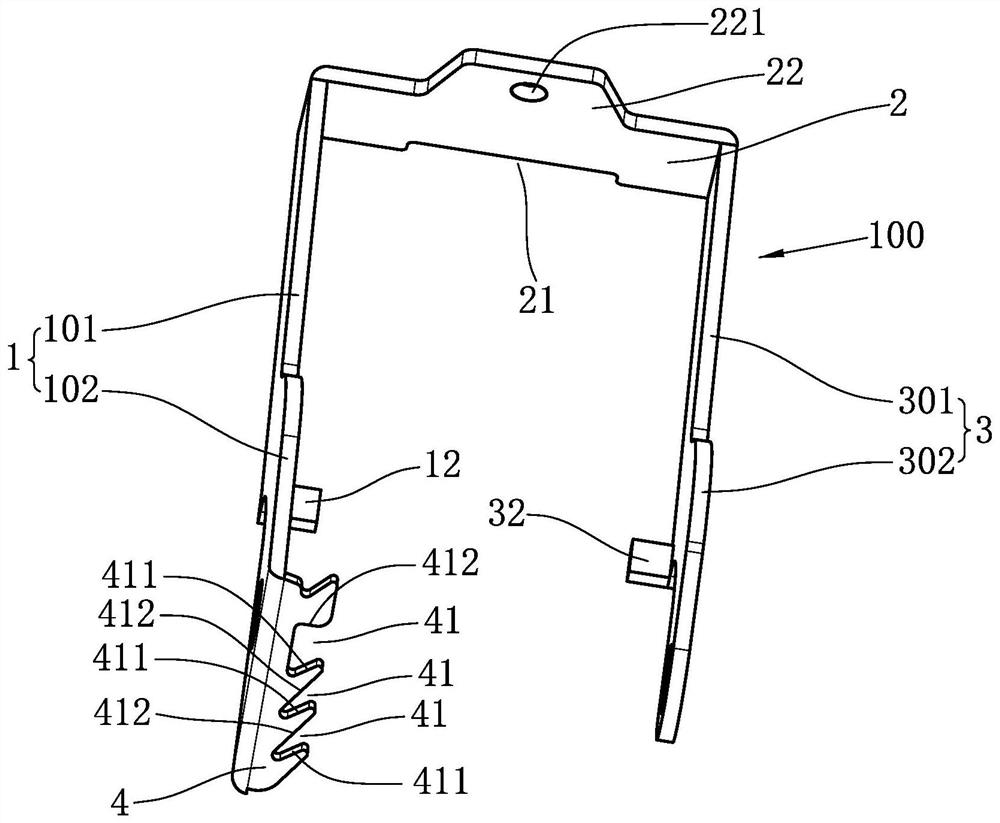

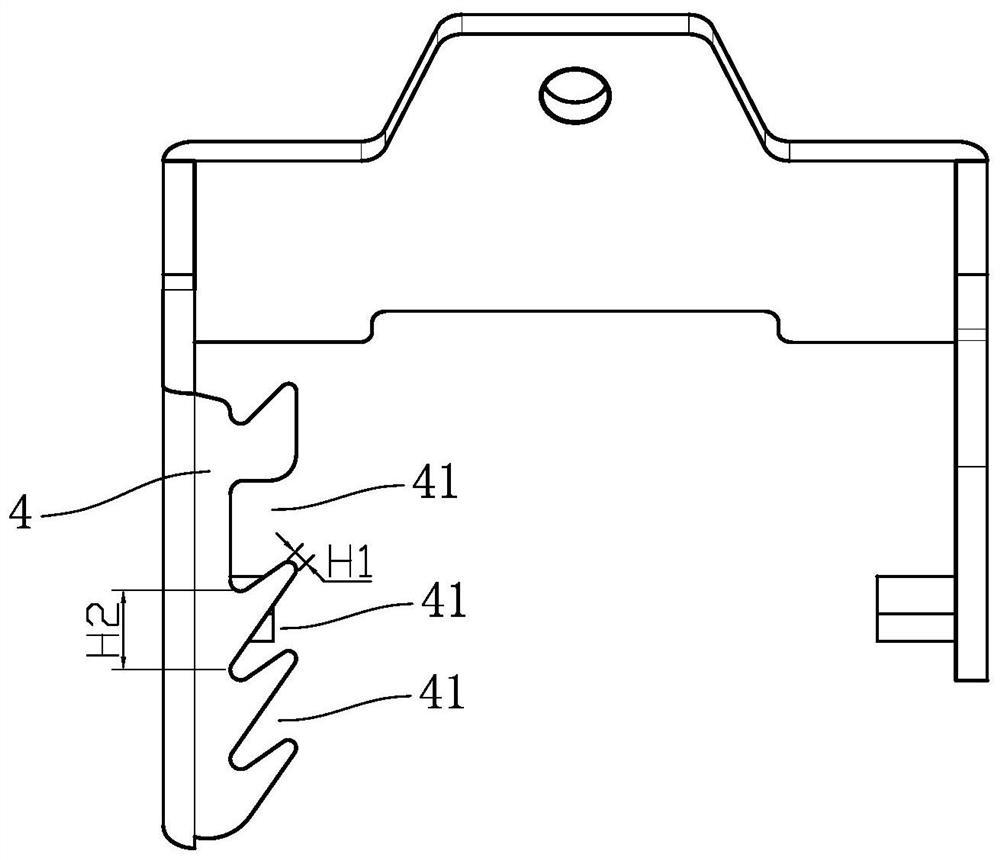

[0029] see figure 2 , the torque adjustment mechanism 100 includes a first connecting plate 1 for connecting the valve body and an adjusting plate 4 arranged inside the first connecting plate 1, the bottom end surface of the adjusting plate 4 is located at the bottom of the first connecting plate 4 in the vertical direction Above the end face, the first connecting plate 1 is provided with a first connecting portion 11, and the adjusting plate 4 is provided with at least two torque adjustment grooves 41 for clamping the upper torsion arms of the first torsion spring, and at least two torque adjustment grooves 41 vertical settings.

[0030] like image 3 As shown, the minimum spacing distance between two adjacent torque adjustment slots 41 is H1, H1≥2mm, and the maximum spacing distance H2 between two adjacent torque adjustment slots 42, H2≤20mm.

[0031] see figure 1 , The torque adjustment mechanism 100 also includes a stop plate 2 for connecting the temperature sensing me...

Embodiment 2

[0038] see Figure 4 and Figure 5 , the fire check valve includes a valve body 200, a valve plate 300, a linkage mechanism 400, a paddle 800, a temperature sensing mechanism 900, a first torsion spring 500, a second torsion spring 700 and a torque adjustment mechanism, and the valve body 200 has an exhaust port 201, a valve seat 2001 is set on the inner wall of the valve body 200, the valve plate 300 is movably set on the upper end of the linkage mechanism 400, the lower end of the linkage mechanism 400 is movably set on the valve seat 2001, and the paddle 800 is movably set On the valve seat 2001, the torque regulating mechanism is the torque regulating mechanism 100 of the first embodiment, the torque regulating mechanism 100 is fixedly connected with the valve seat 2001, the temperature sensing mechanism 900 is arranged on the torque regulating mechanism 100, and the first torsion spring 500 is arranged on the connecting On the rod mechanism 400, one torsion arm of the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap