Process for treating an ophthalmic lens

A spectacle lens and lens technology, which is applied in the direction of thin material processing, glasses/goggles, coating, etc., and can solve problems such as difficulty in handling lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0124] deposited on CR39 performed on the substrate of the base ophthalmic lens, the CR39 The base ophthalmic lens comprises on both sides a polysiloxane type abrasion resistant coating corresponding to Example 3 of patent application EP614957. Wash the lenses in an ultrasonic cleaning vessel; and steam at a temperature of 100°C for a minimum of 3 hours. They are then ready for processing.

[0125] Two different types of lenses are processed:

[0126] - round lenses,

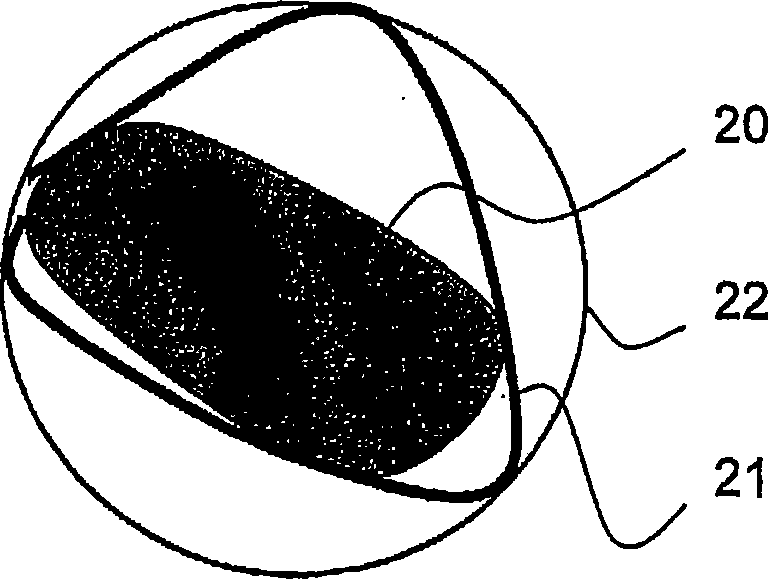

[0127] -Such as figure 2 Pre-calibrated lenses shown.

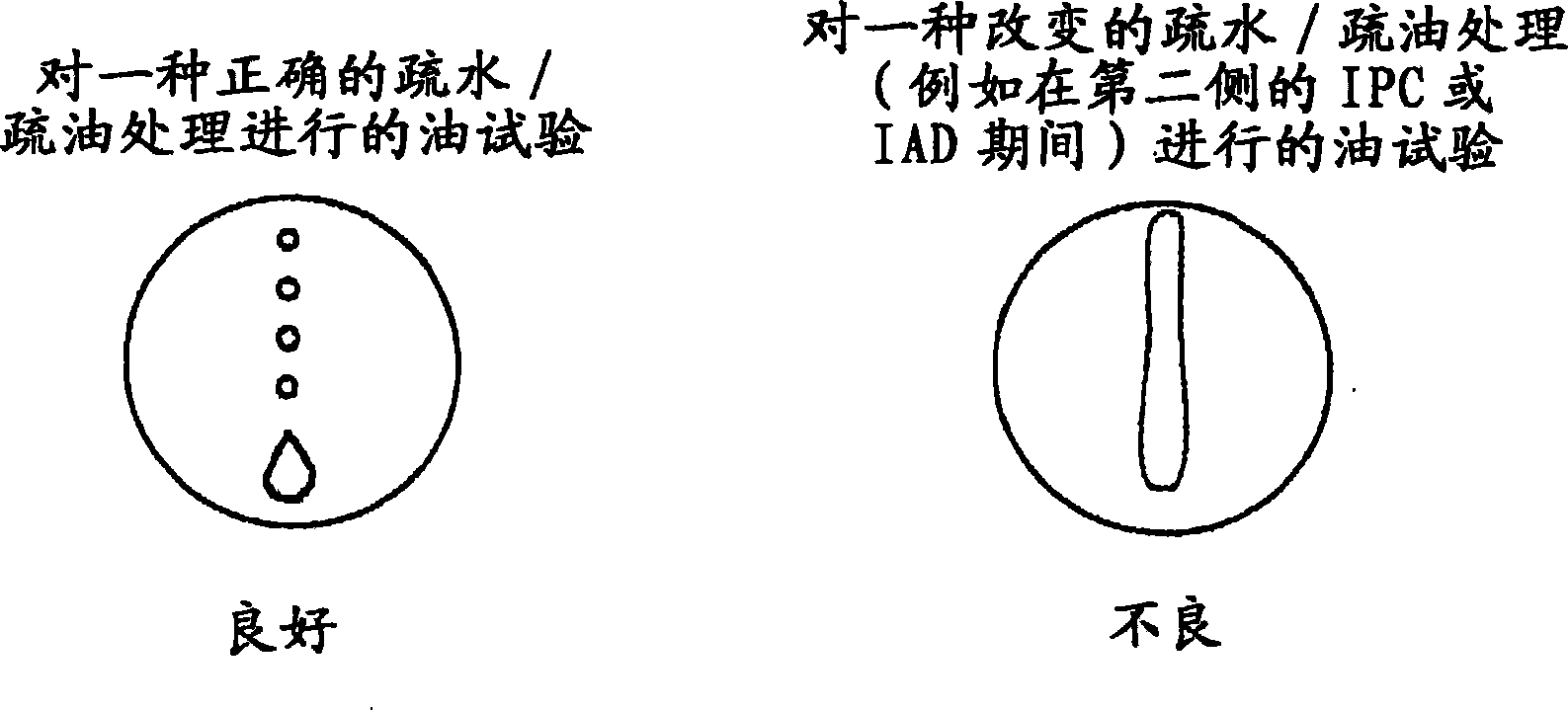

[0128] 1.1 Preparation of Lenses Comprising an Antireflective Hydrophobic and / or Oleophobic Coating

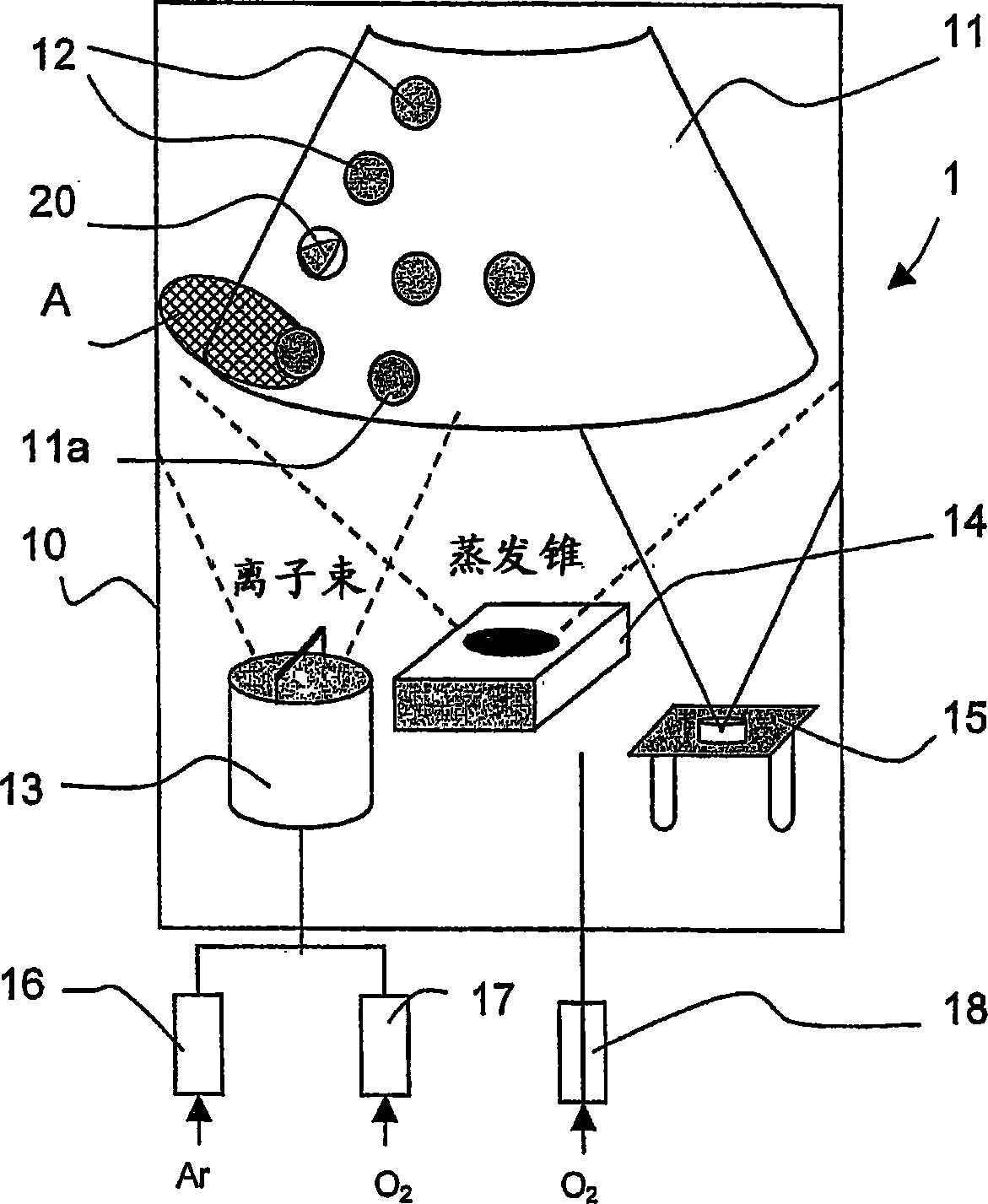

[0129] The vacuum processing unit used was a BalZers BAK 760 unit equipped with an electron gun, an "end-Hall" Mark 2 Commonwealth type ion gun and a Joule effect evaporation source.

[0130] The mirror is placed on a carousel with the concave side exposed to the evaporation source and ion gun.

[0131] The circular lenses are placed on the outer...

example 2

[0153] The substrates were the same painted CR39 as those used in Example 1 Spectacle lenses. They were washed in an ultrasonic cleaner and steamed at a temperature of 100°C for a minimum period of 3 hours.

[0154] 2.1 Preparation of Lenses Including Hydrophobic and / or Oleophobic Coatings

[0155] The vacuum processing apparatus used was a Leyhold LH1104 type apparatus equipped with an electron gun, a Mark2 type ion gun and a Joule effect evaporation source.

[0156] The mirror is placed on a carousel with the concave side exposed to the evaporation source and ion gun.

[0157] Circular lenses are placed on the outer crown (in the most sensitive zone for processing) of the carousel and in the central part of the carousel.

[0158] Pre-aligned lenses are also placed on the crown and center sections of the carousel.

[0159] Vacuum pumping is performed until a second vacuum is reached.

[0160] Thereafter, sequential evaporation was performed by heating the evaporation sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com