Particulate matter detection element, particulate matter detection sensor, and method of manufacturing particulate matter detection element

a technology of particulate matter and detection element, which is applied in the direction of instruments, structural/machine measurement, suspensions, etc., can solve the problems of difficult to achieve with conventional thick-film printing, and achieve the effect of minimizing the electric field concentration, stable detection accuracy, and minimizing the variation in insensible mass due to local deposition of particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

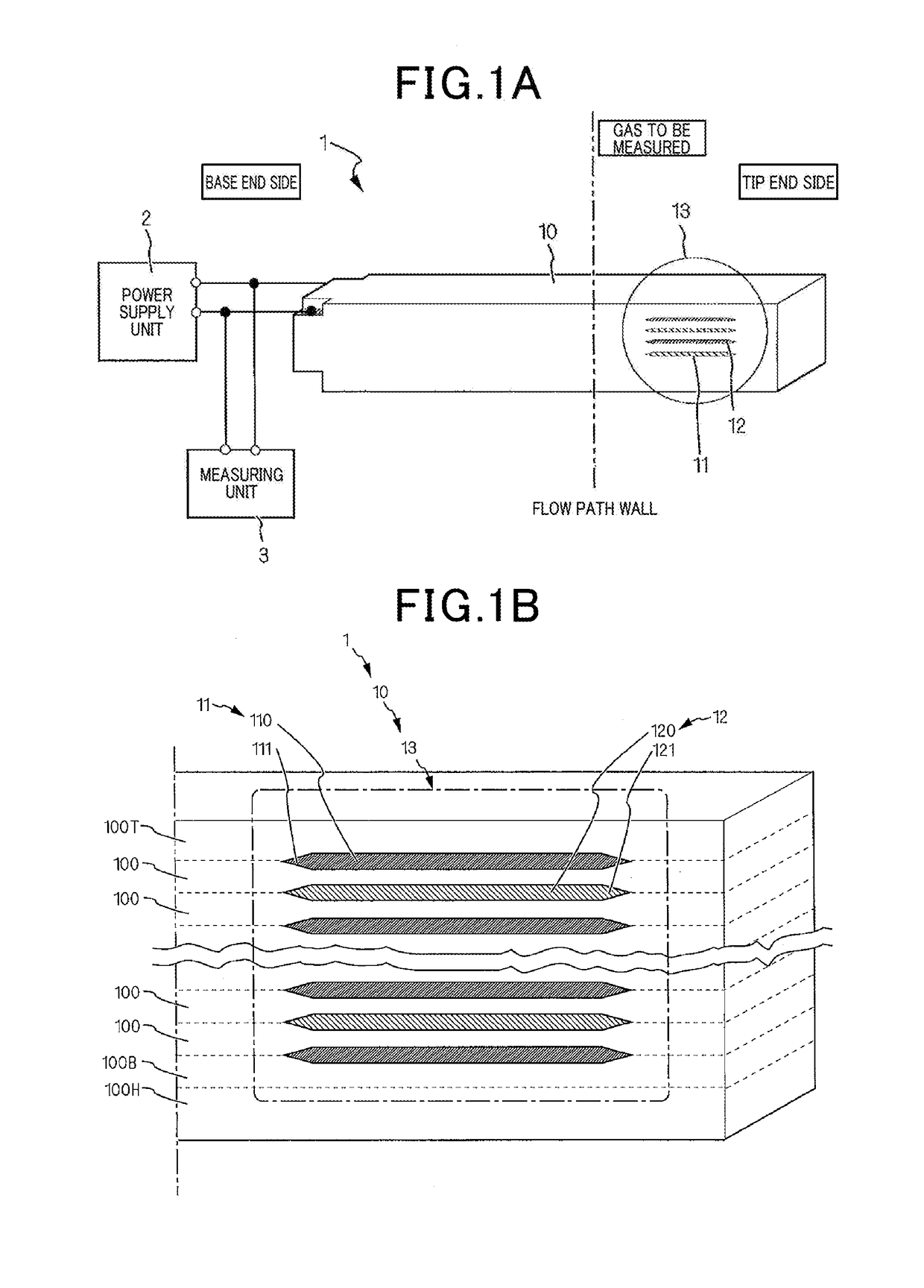

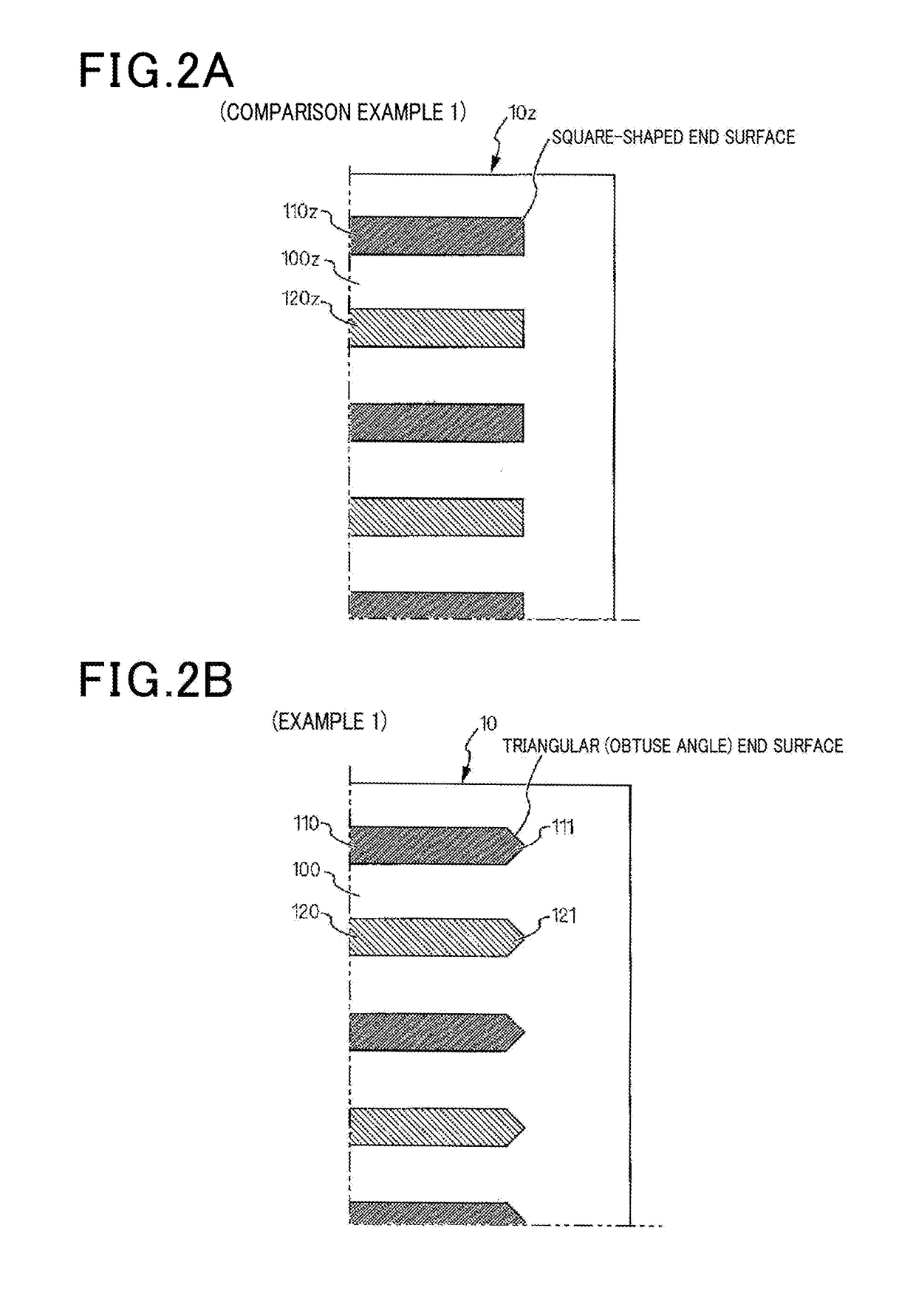

[0045]With reference to FIGS. 1A, 1B, and 1C, hereinafter is described an outline of a particulate matter detection sensor 1 according to a first embodiment of the present disclosure and a particulate matter detection element 10 that is a major part of the present disclosure.

[0046]The particulate matter detection sensor 1 (hereafter referred to as sensor 1) of the present disclosure is configured by the particulate matter detection element 10 (hereafter referred to as element 10), a power supply 2, and a measuring unit 3. The element 10 includes a detecting unit 13 which is disposed in a gas to be measured that is an exhaust gas of an internal combustion engine. The power supply 2 applies a predetermined voltage to the element 10. The measuring unit 3 measures electrical characteristics, such as changes in current flowing through the element 10, and changes in voltage and impedance of the element 10, to detect particulate matter in the gas to be measured.

[0047]Electrical characteris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical characteristics | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com