Airbag cover and method for its production

A technology of molded parts and plastics, applied in household components, vehicle parts, vehicle safety arrangements, etc., can solve the problems of expensive and high-consumption separation media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

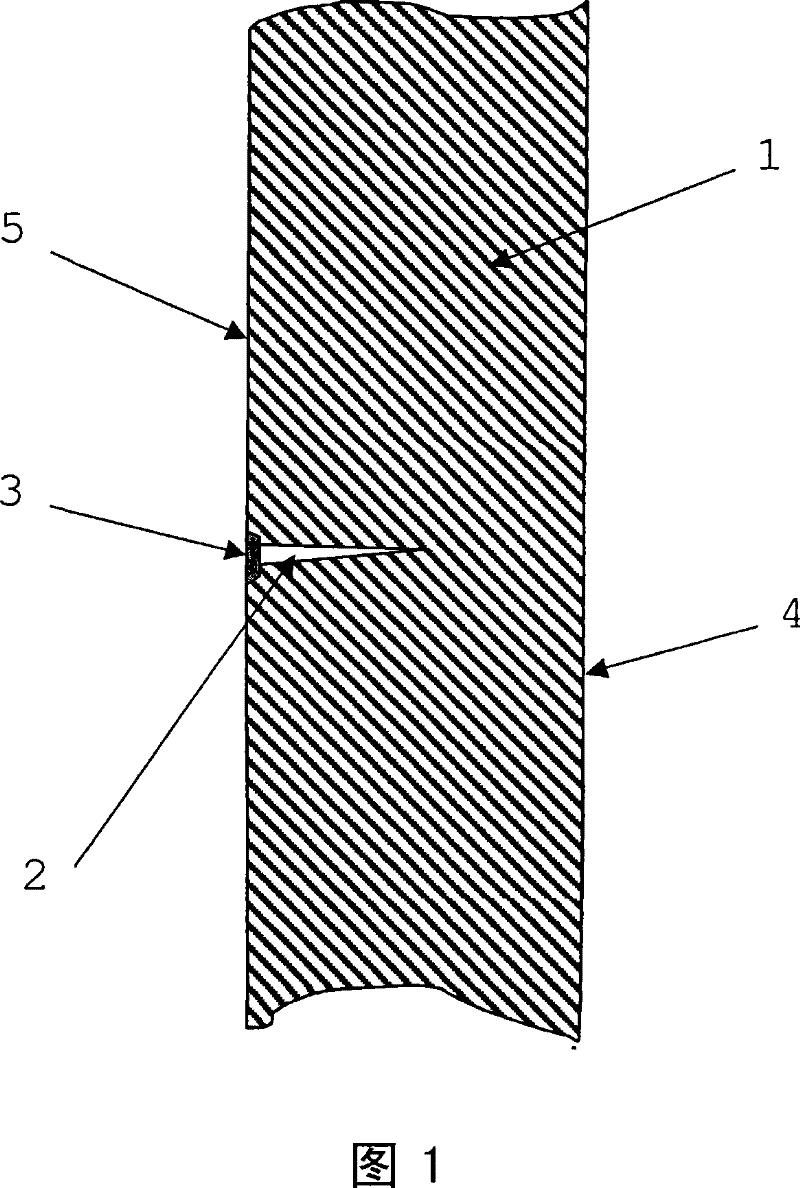

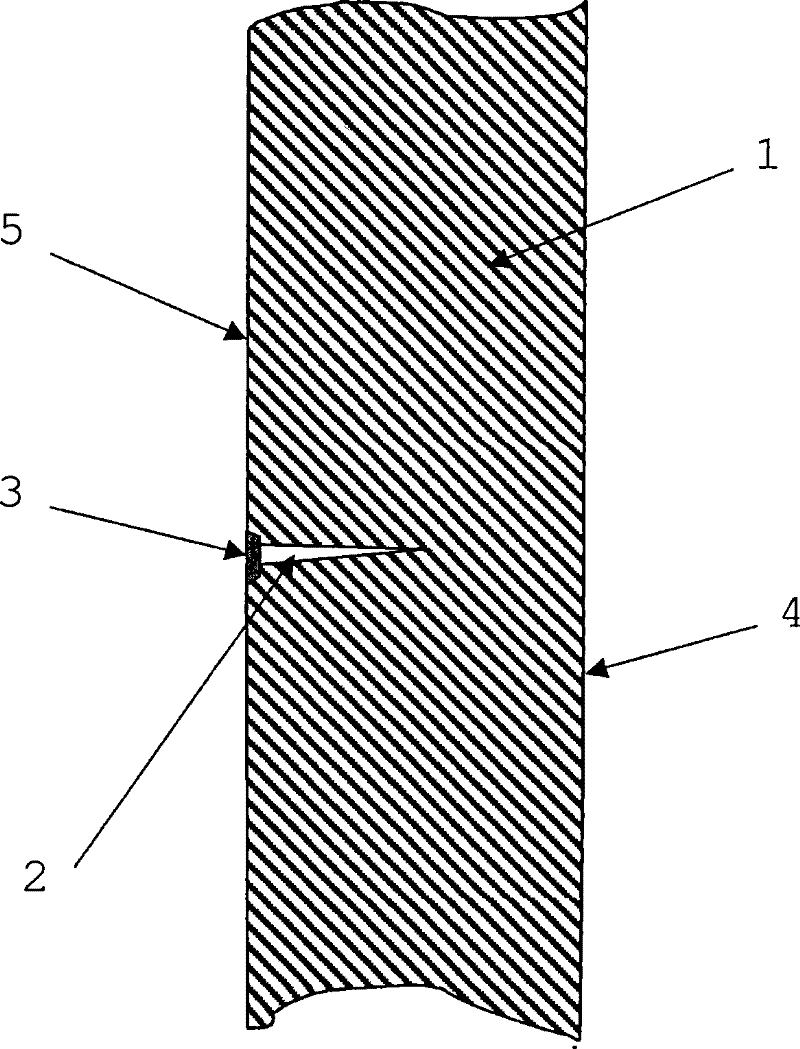

[0016] The decorative film consists of a decorative side 4, shown as the visible side in the vehicle compartment, and a decorative lower side 5 arranged in the direction of the airbag, in which there is a closed 3 formed by a cutout. Sealing provision disconnects line 2.

[0017] like figure 1 In the embodiment shown, the invention is realized by means of a single-layer decorative film, which is formed, for example, by simple leaching. Furthermore, the invention can also be made possible by a multi-layered decorative film produced, for example, by a double-layer casting process, in which an additional foam layer is formed on the underside of the decorative surface, thus stabilizing the entire A decorative film, and improving the tactile feeling of the decorative film. In the case of a multilayer embodiment, the decorative film is also produced from a single material type, wherein only the processing method is changed, and a decorative side is formed compactly, whereas only t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com