Inner flap gate

A technology of inner flaps and gates, applied in the arrangement of bells and funnels, containers, packaging, etc., can solve the problems of difficulty in closing gates and difficult to solve dust, and achieve the effect of easy maintenance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

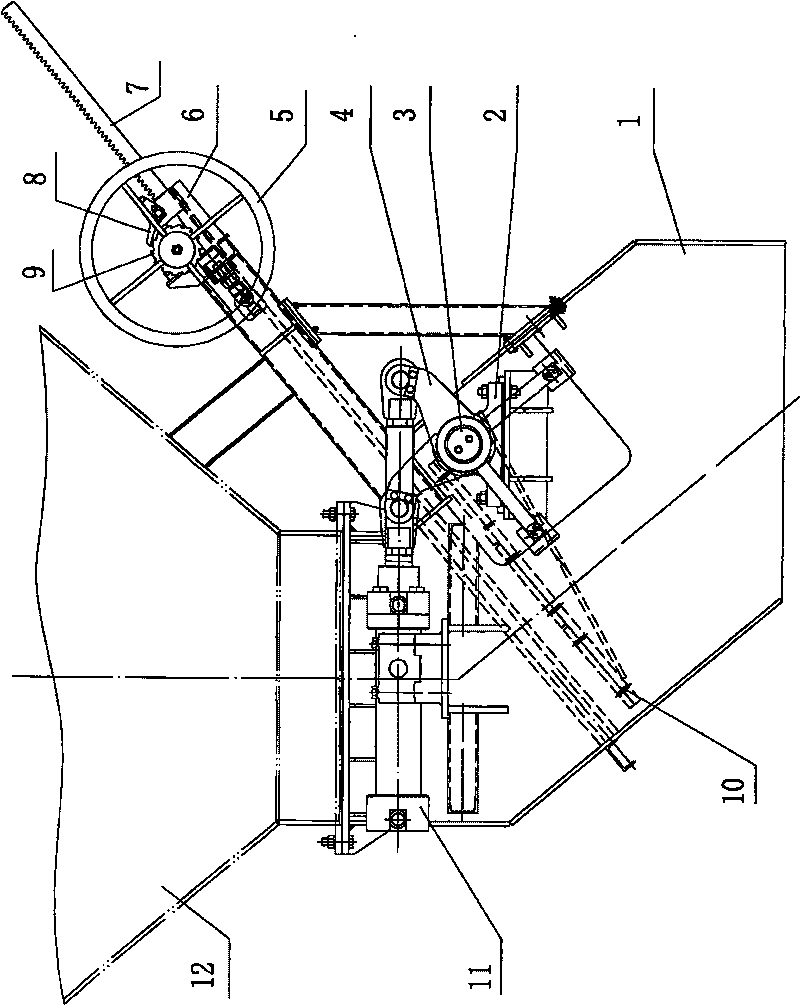

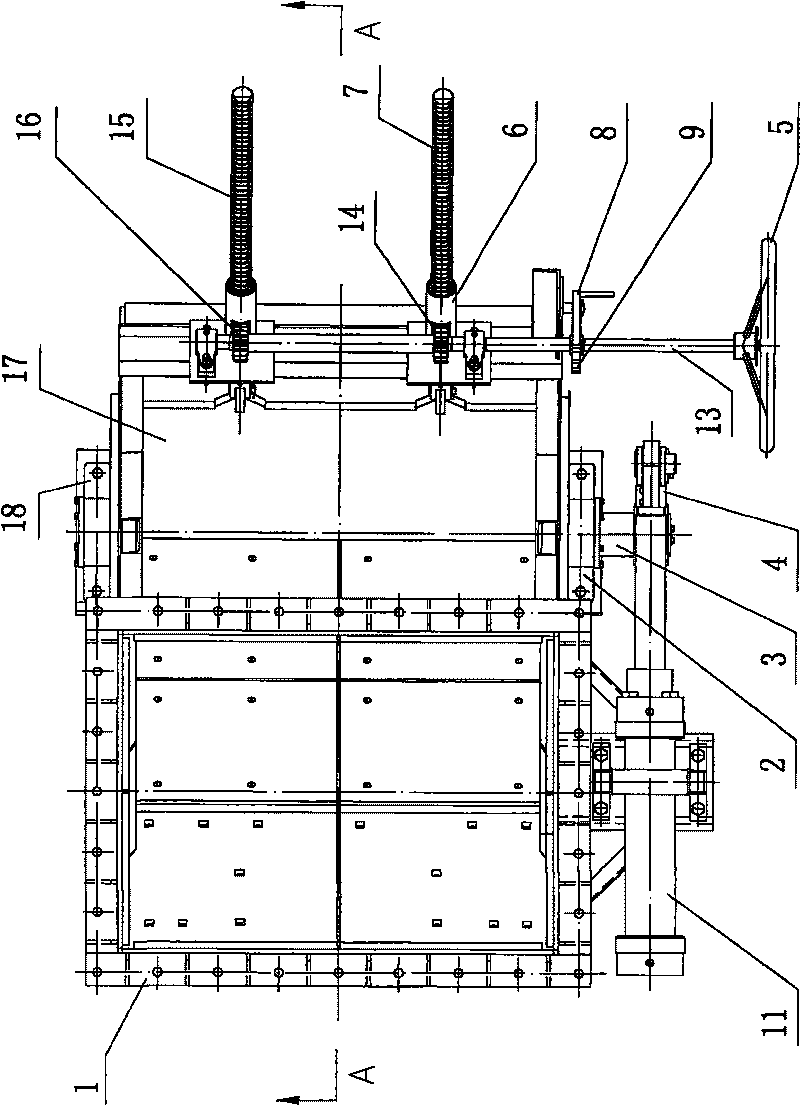

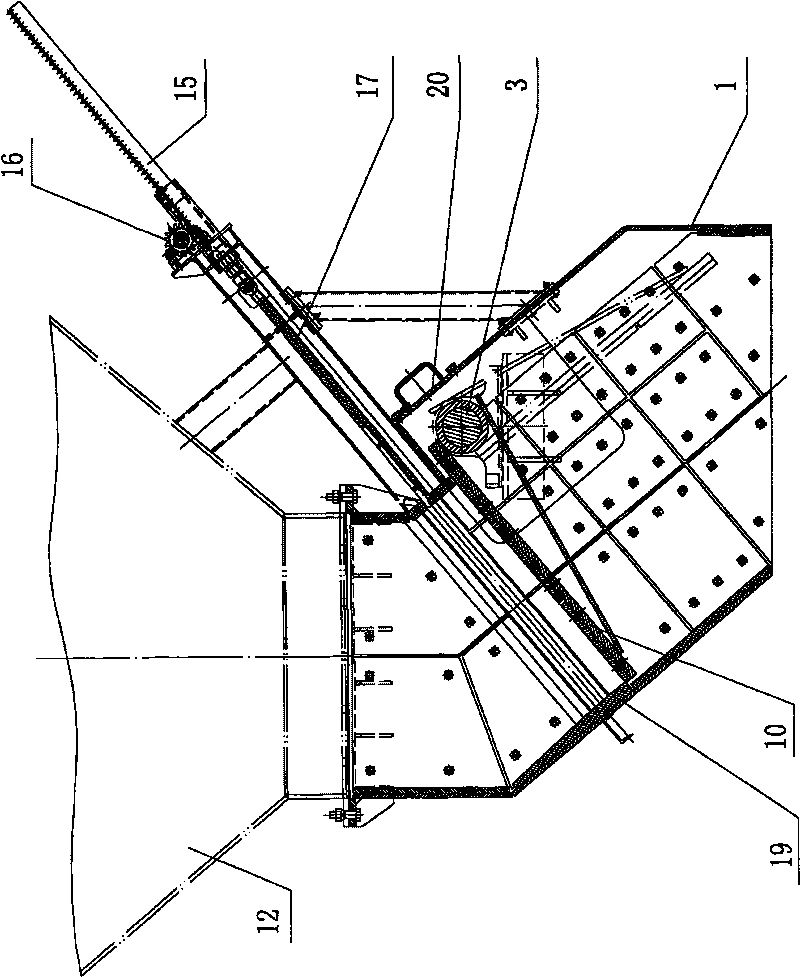

[0014] Such as figure 1 , figure 2 , image 3 As shown, the inner flap gate includes a housing 1, a turning mechanism, an inner flap 10, a moving mechanism, and a flow regulating plate 17; the inside of the housing 1 is a cavity, and the upper and lower ends of the housing 1 are open ends. The upper end of the body 1 is fixedly connected with the lower end of the silo 12 (fixed by flanges and bolts); the housing 1 is provided with a flow regulating plate hole, and the flow regulating plate hole communicates with the cavity of the housing 1, and the flow regulating plate 17 One end is inserted into the hole of the flow regulating plate, and the other end of the flow regulating plate 17 is hinged with the moving mechanism; the inner flap 10 is located in the cavity of the housing 1, and the inner flap 10 is located below the hole of the flow regulating plate (that is, it is located in the flow regulating plate 17), one end of the inner turning plate 10 is fixedly connected (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com