Steel bridge folding temporary locking method

A temporary locking, rigid-frame bridge technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of high engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

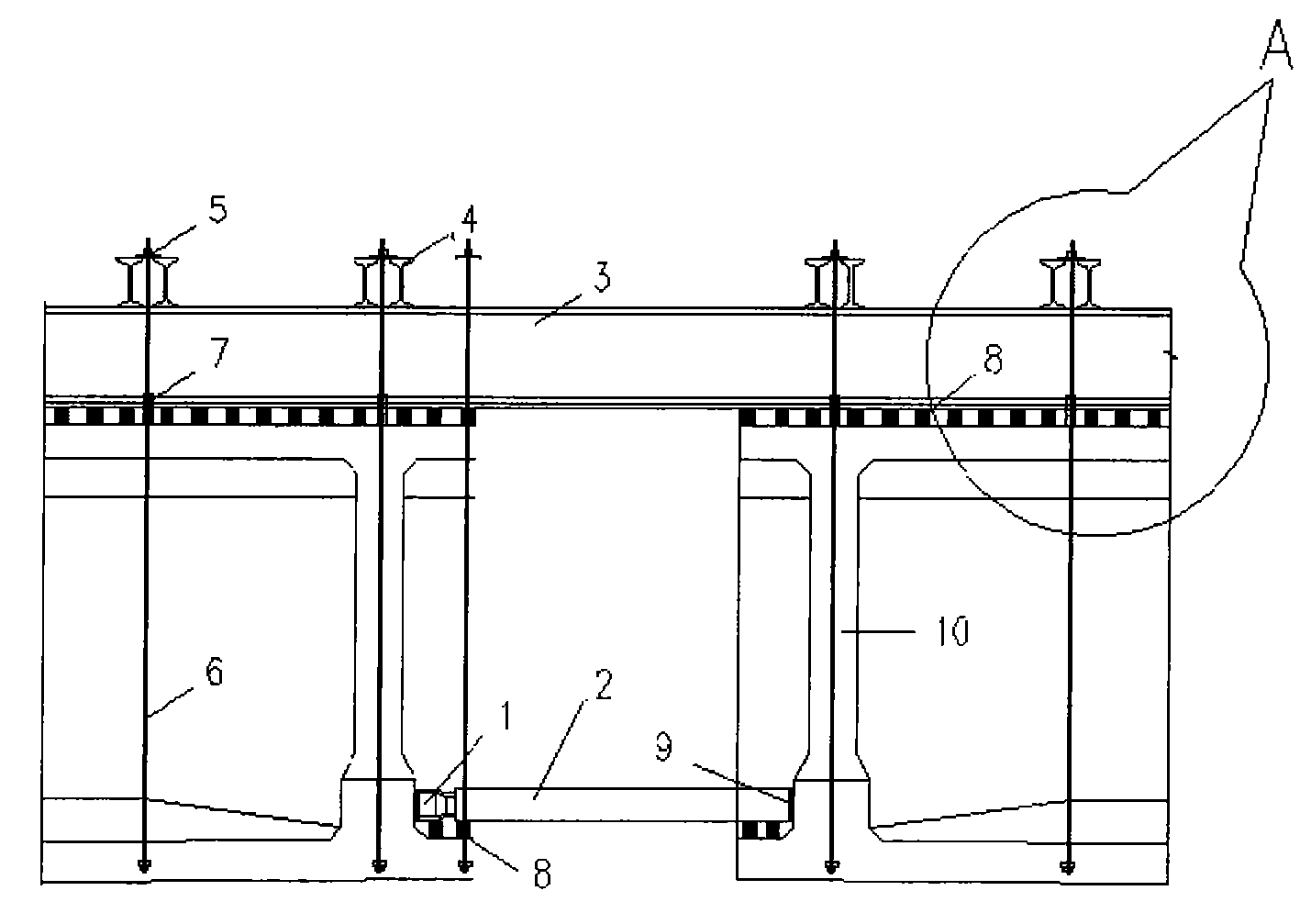

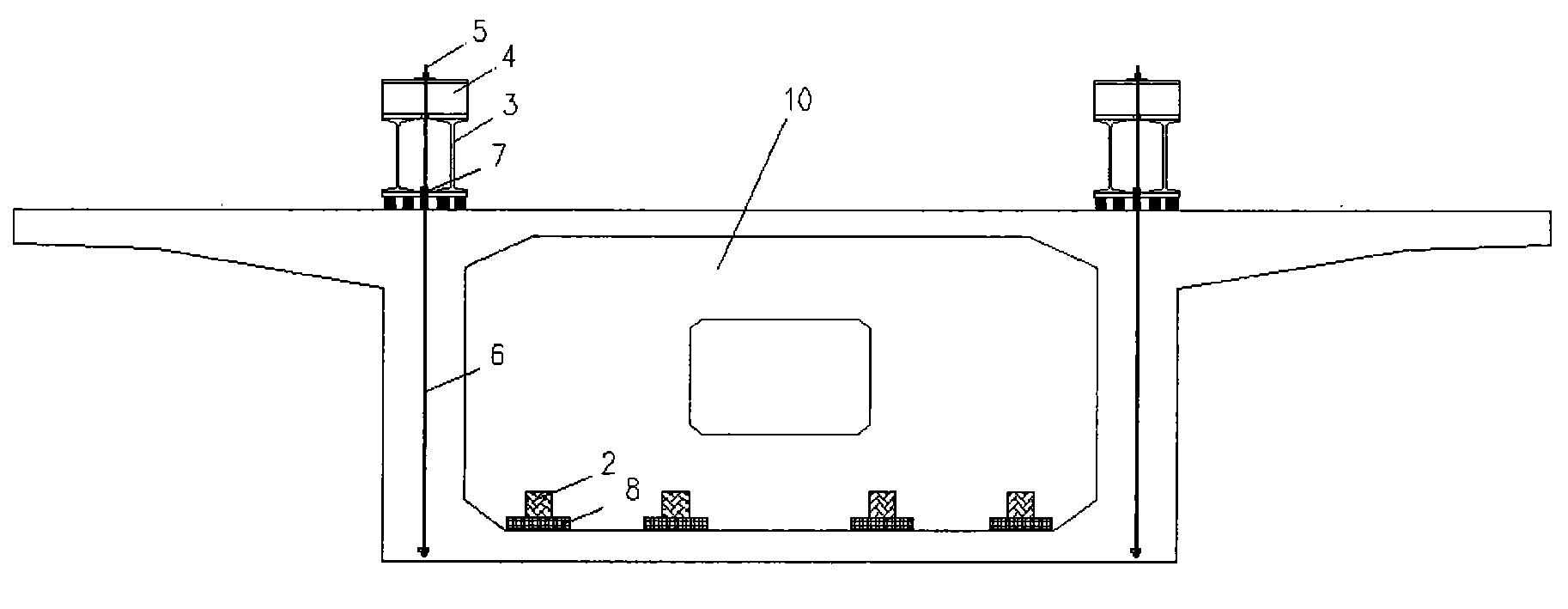

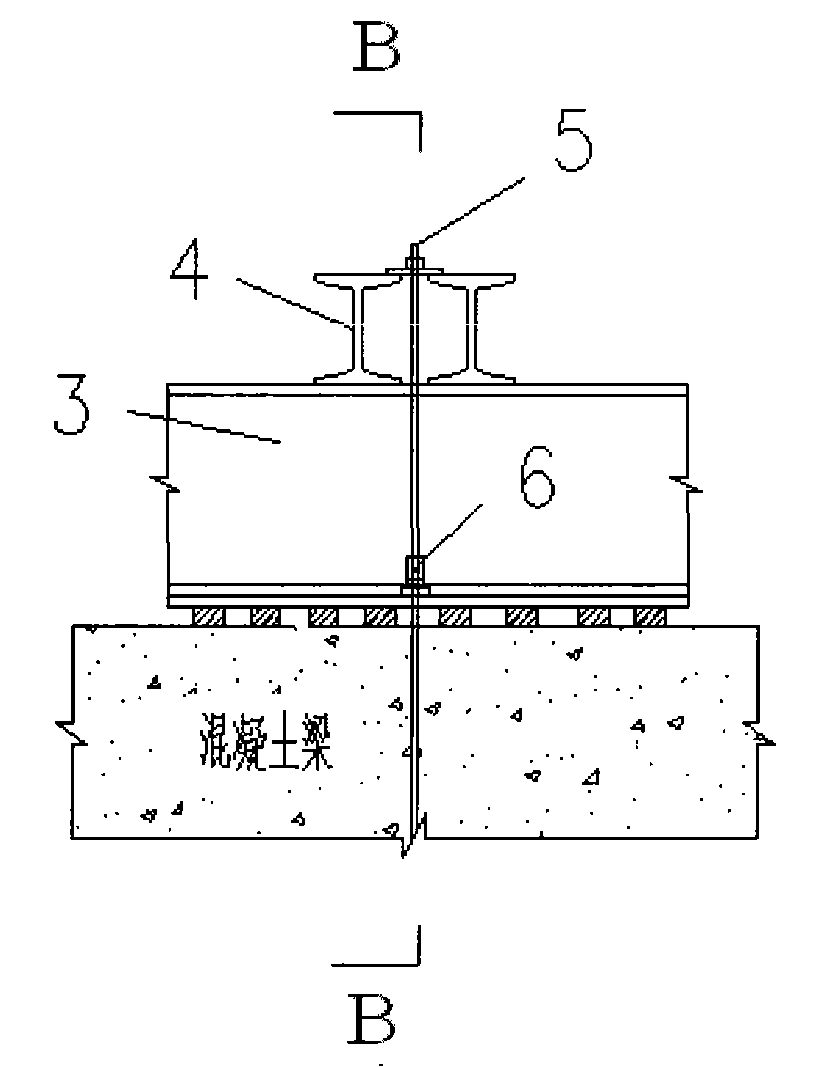

[0018] Such as Figure 1 to Figure 4 As shown, the present invention provides a kind of rigid frame bridge closing temporary locking method, comprises the following steps:

[0019] A. After the cantilever construction of the rigid-frame bridge is completed, place eight pads 8 on the upper surface of the box girder floor of the two cantilever end segments of each mid-span on the left and right sides of the closing mouth and level them, respectively on the left and right sides. A connecting rod 2 is placed on the pad 8 opposite to the box girder and a jack 1 is set between one end of the connecting rod 2 and the web of the box girder;

[0020] Evenly apply force to each jack 1, and ensure that the piston elongation of the four jacks 1 is basically the same during the loading process, so that the opening of the closing opening meets the required distance, and the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com