Method for calibrating coordinates of touch control screen

A calibration method and touch screen technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve problems such as display configuration mismatch, and achieve the effect of solving configuration mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the following will specifically cite preferred embodiments, in conjunction with the accompanying drawings, and describe them in detail as follows.

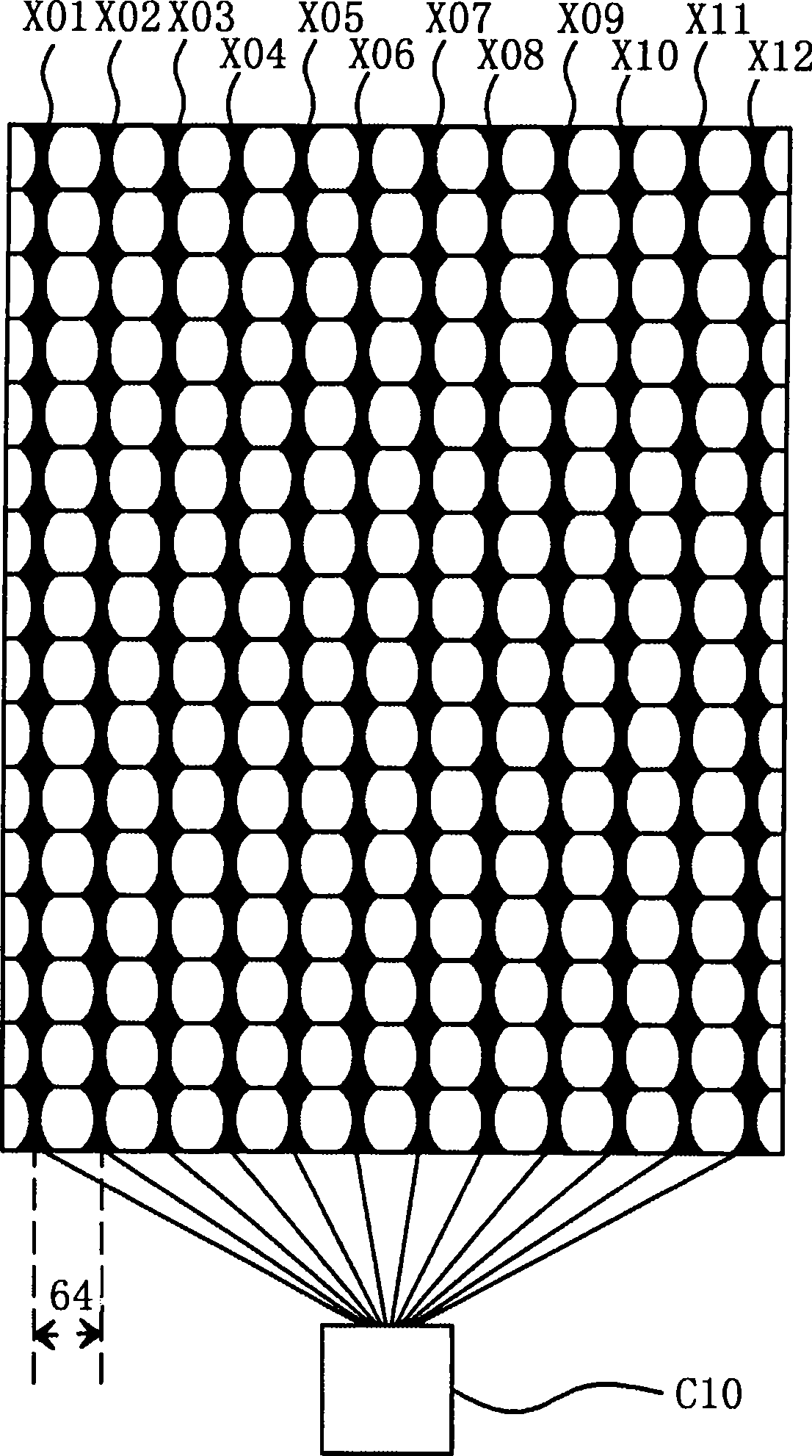

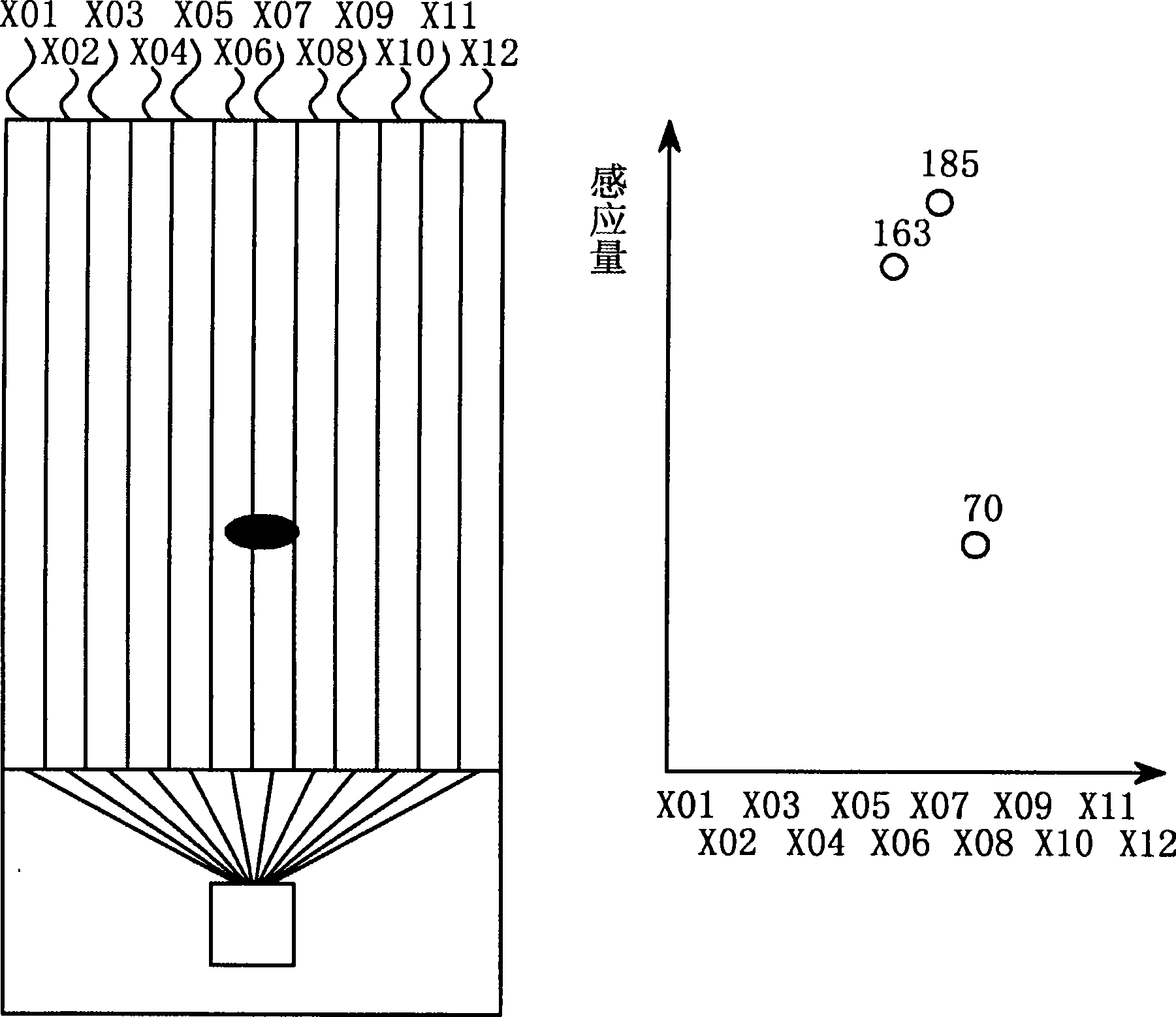

[0028] figure 1 It is a structural cross-sectional view of a capacitive touch screen according to an embodiment of the present invention. Please refer to figure 1 The capacitive touch screen includes a display module 40 and a capacitive sensor 41. figure 2 It is a top view of the structure of the capacitive sensor 41 according to an embodiment of the present invention. Please refer to figure 2 The capacitive sensor 41 includes a plurality of X-axis sensing electrodes X01 to X12 and a control circuit C10. Since the positioning index requires an X-axis coordinate and a Y-axis coordinate, this embodiment only provides a method for positioning the X-axis coordinate, and the Y-axis coordinate positioning method ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap