Method of manufacturing a micromechanical part

一种机械部件、部件的技术,应用在这种类型的部件领域,能够解决损坏这种部件、复杂、可微加工材料摩擦性能不足等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

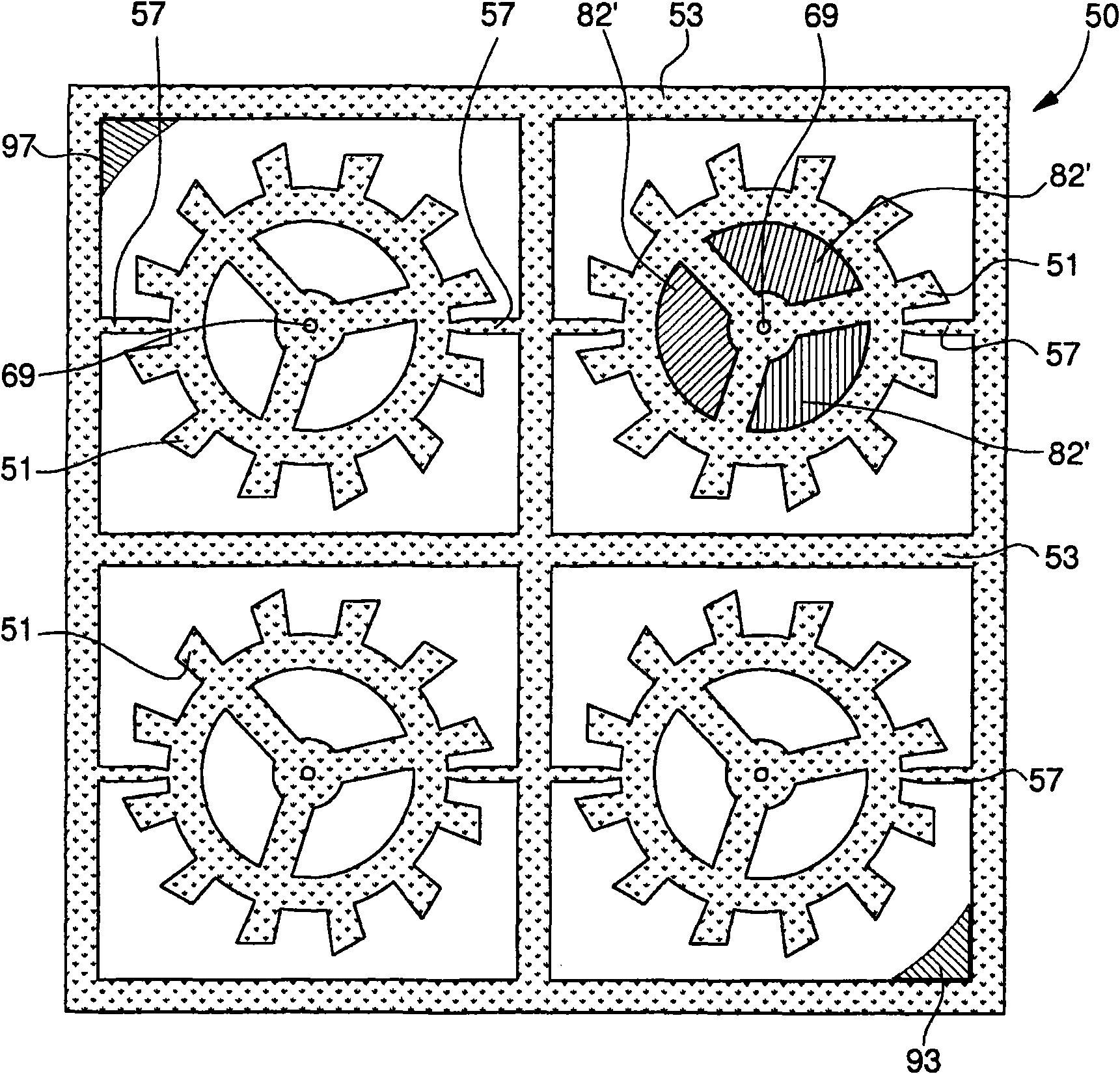

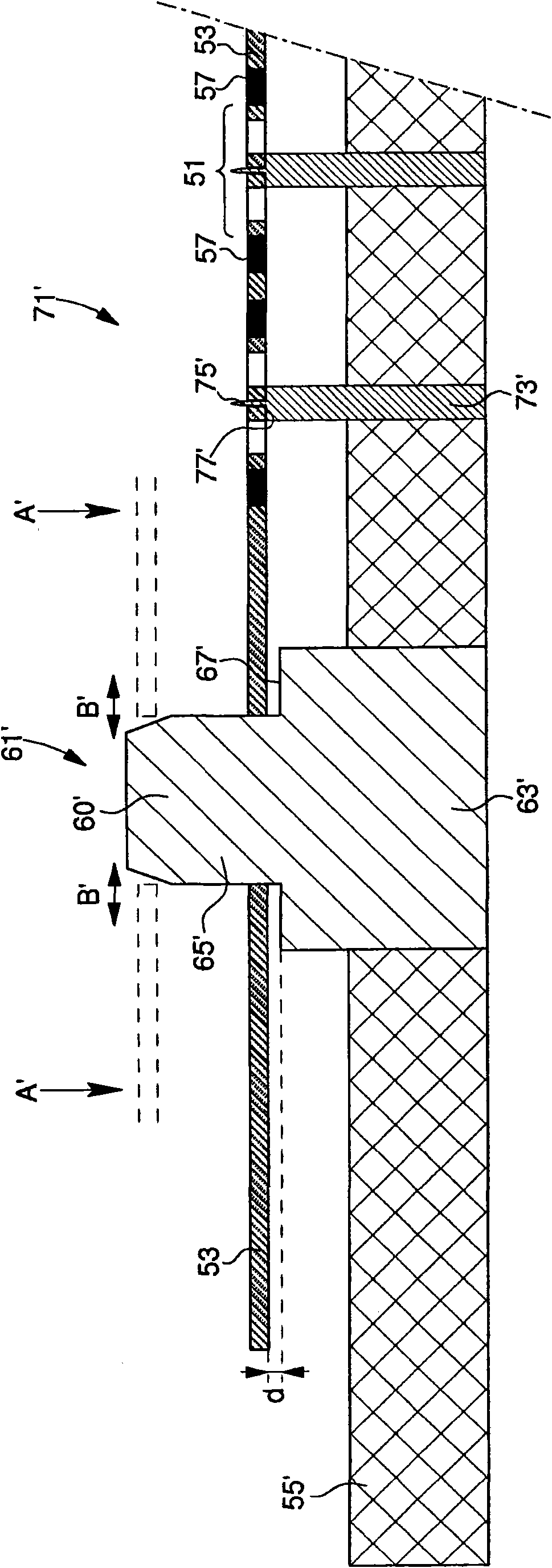

[0033] shown in Figure 8 The example of FIG. 1 shows a flowchart of the method generally indicated with reference number 1 . Method 1 mainly comprises 6 steps 3, 5, 7, 9, 11 and 13 for manufacturing a mechanical part 51 whose core is made of a micromachinable material substrate. In fact, micromachinable materials, due to their precision of less than 1 micron, are particularly advantageous for the manufacture of, for example, watch components and advantageously replace the commonly used metallic materials.

[0034] In the description below, the micromachinable material may be a crystalline silicon-based material, such as single crystal silicon; crystalline silica, such as quartz; or crystalline alumina, such as corundum (also known as synthetic sapphire). Obviously, other micromachinable materials are conceivable.

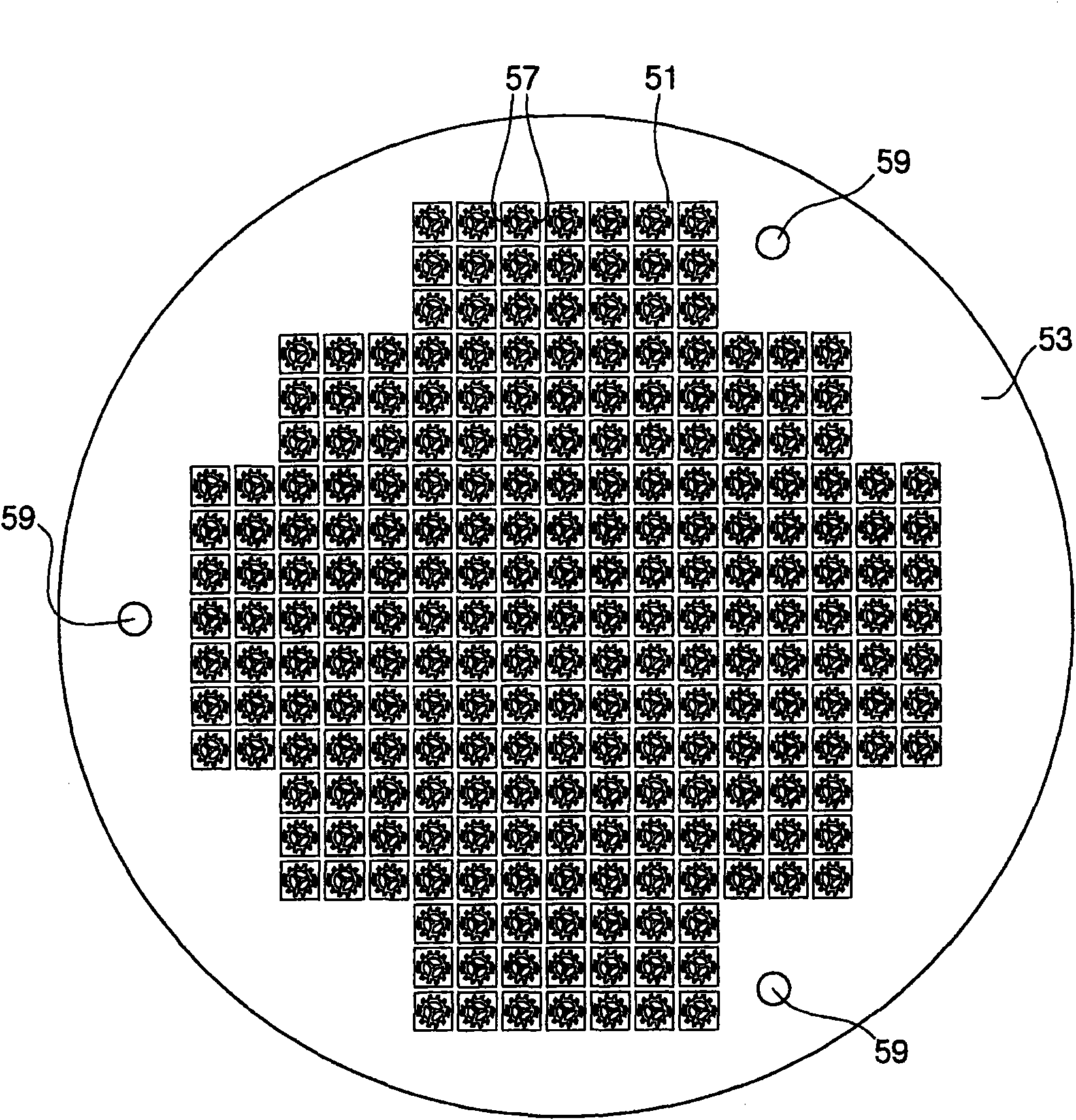

[0035] Step 3 consists of obtaining a substrate 53 made of a micromachinable material similar to, for example, single crystal silicon wafers used in the manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com