Preprocessing method and system before trapping

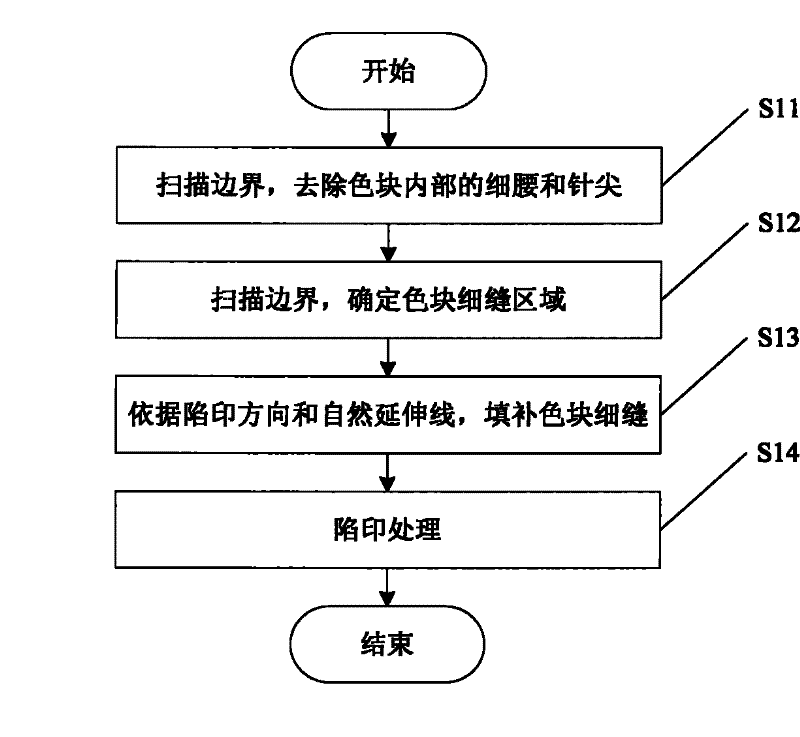

A preprocessing and one-to-one technology, applied in the direction of digital output to printing unit, visual demonstration using printer, electrical components, etc., can solve the problems such as the inability to determine the thin waist of the color block and the position of the needle tip, and the inability to fill the slit, etc., to achieve the guarantee Trapping effect, the effect of making up for design errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0067] A preprocessing system before trapping, including the following devices:

[0068] Waist and needle point removal device, used to scan the border of the color block and remove the waist and needle point inside the color block;

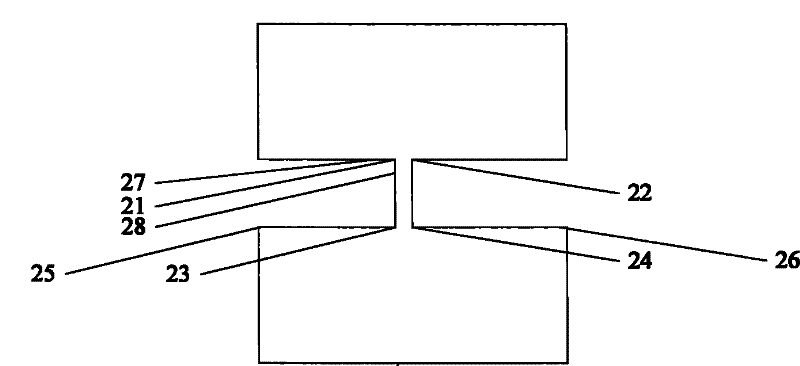

[0069] A color block slit scanning device, used to scan the boundaries of adjacent color blocks, and determine the color block slit area between adjacent color blocks;

[0070] The color block slit filling device fills the color block slit according to the trapping direction between the color blocks on both sides of the color block slit and the intersection of the natural extension line of the color block and the adjacent color block.

[0071] A trapping device, which is used to judge whether the trapping conditions are satisfied, determine the trapping direction, generate the shape of the trapping area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com