Fire-retardant door

A fire-resistant door and fire-resistant glass technology, applied in the field of fire-resistant doors, can solve problems such as limited supply and demand, expensive fire-resistant glass, and increased production cost burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

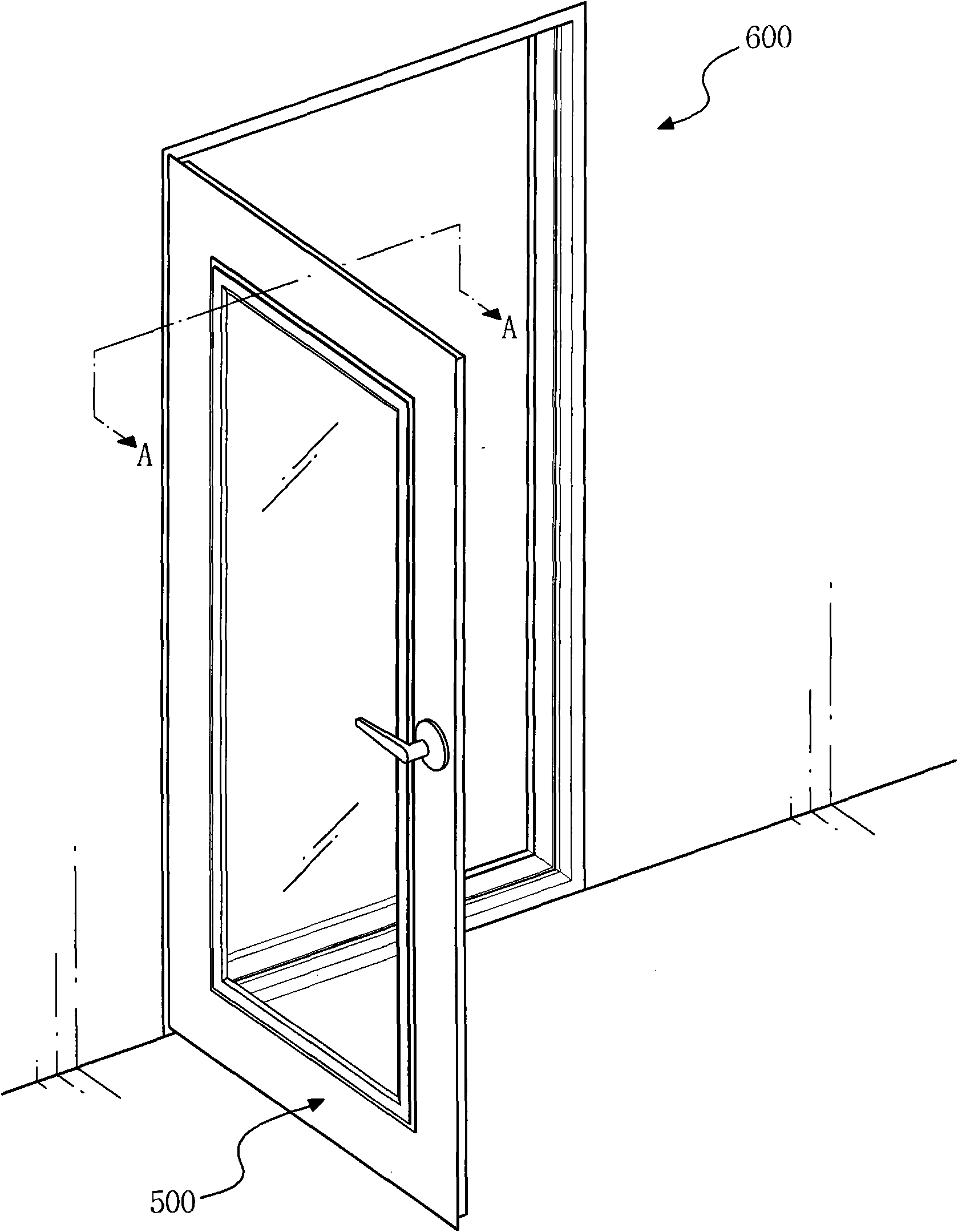

[0022] Hereinafter, a fire door according to one embodiment of the present invention will be described in more detail with reference to the accompanying drawings.

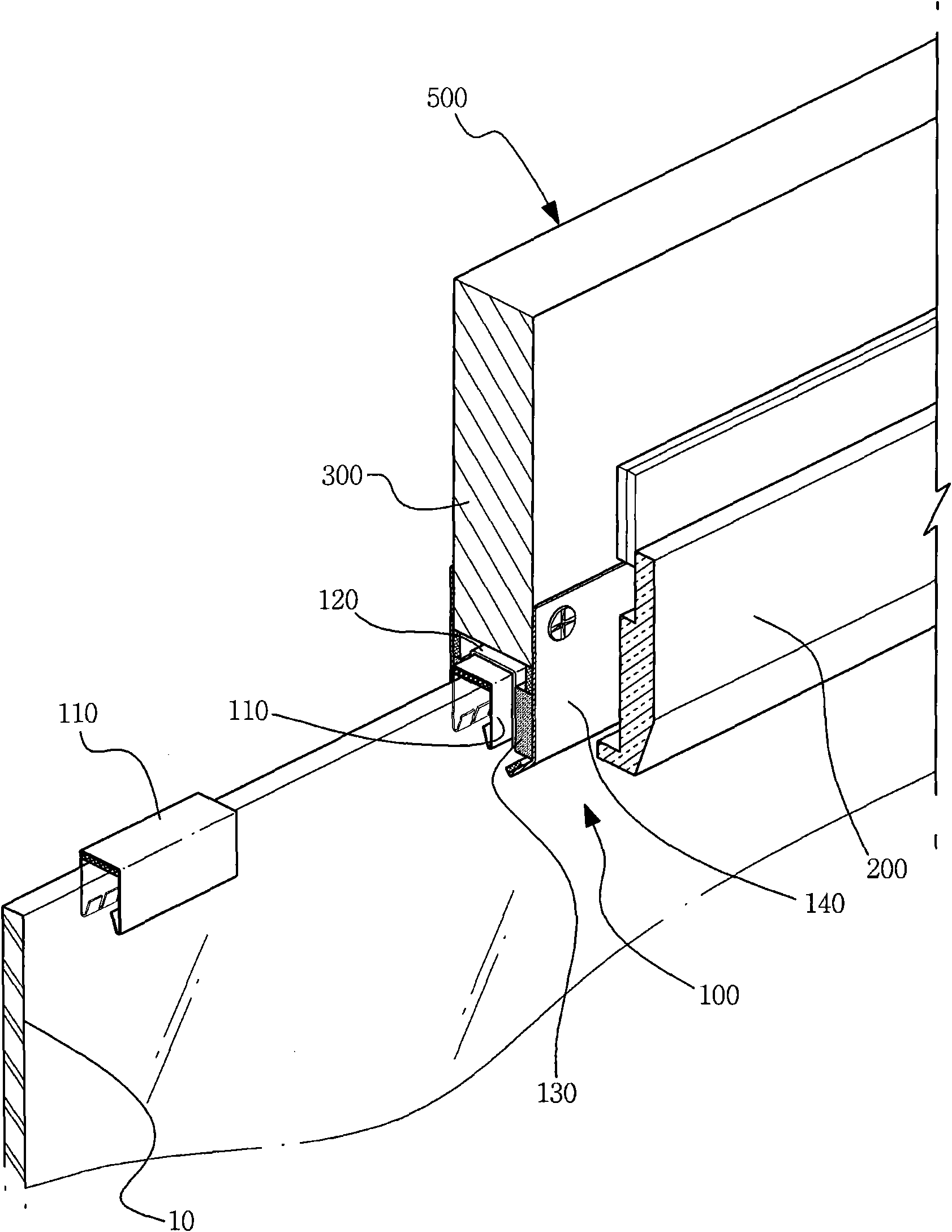

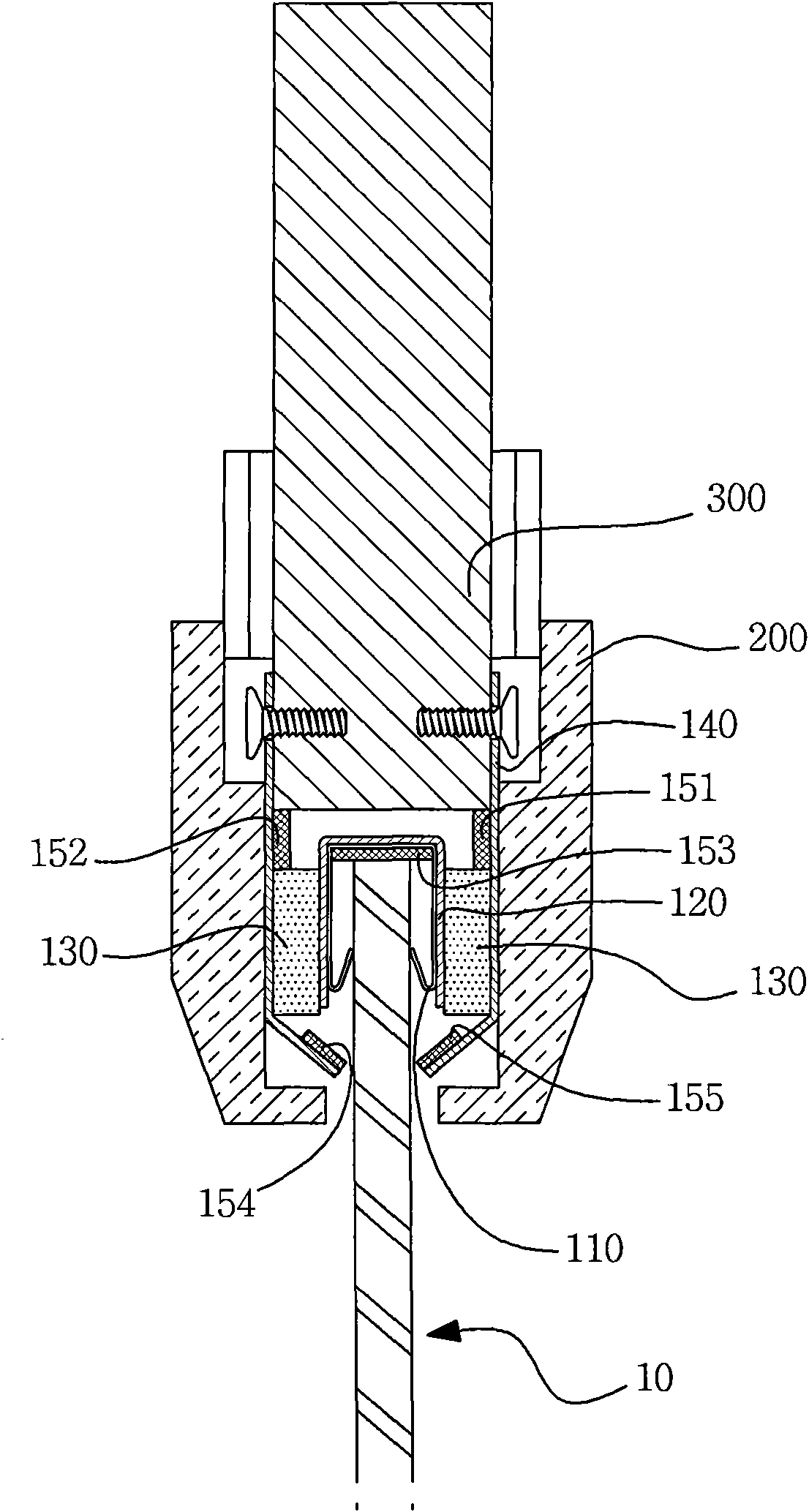

[0023] figure 1 To show a perspective view of an example of a fire door according to one embodiment of the present invention, figure 2 for along figure 1 An enlarged perspective view of the line A-A, and image 3 for along figure 1 A detailed cross-sectional view of line A-A.

[0024] The fire door 500 according to the embodiment includes a frame-shaped bracket 300 having a groove formed thereon, a fireproof glass 10 placed in the groove of the bracket and supported on the bracket 300, and a frame for supporting the fireproof glass 10 to the The supporting part 100 on the bracket 300 .

[0025] The support member 100 includes an elastic member 110 contacting both surfaces of the edge portion of the fireproof glass 10 , a fixing plate 140 fixed to the bracket 300 and in contact with both side surfaces of the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap