Method of radially expanding a tubular element

A technology of tubular components and expansion tubes, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., and can solve problems such as the risk of tube expander stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the drawings and the description, like numerals refer to like parts.

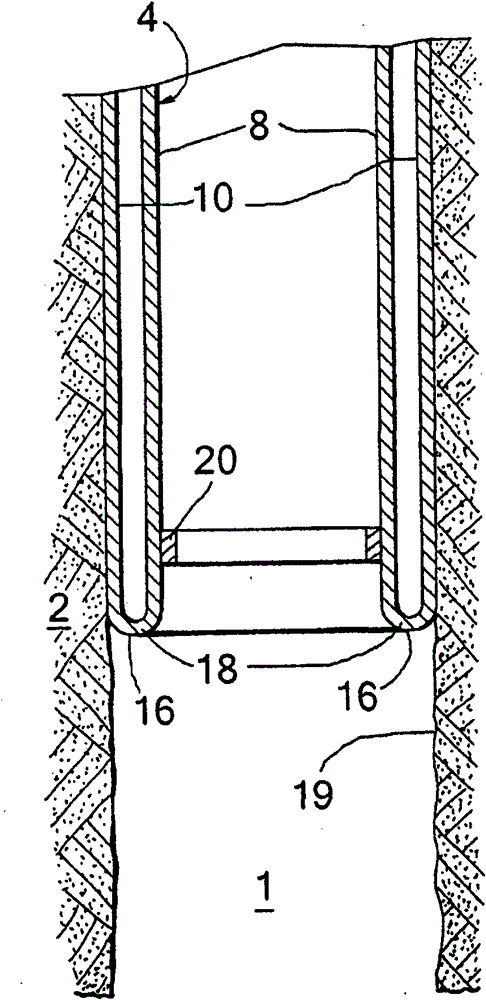

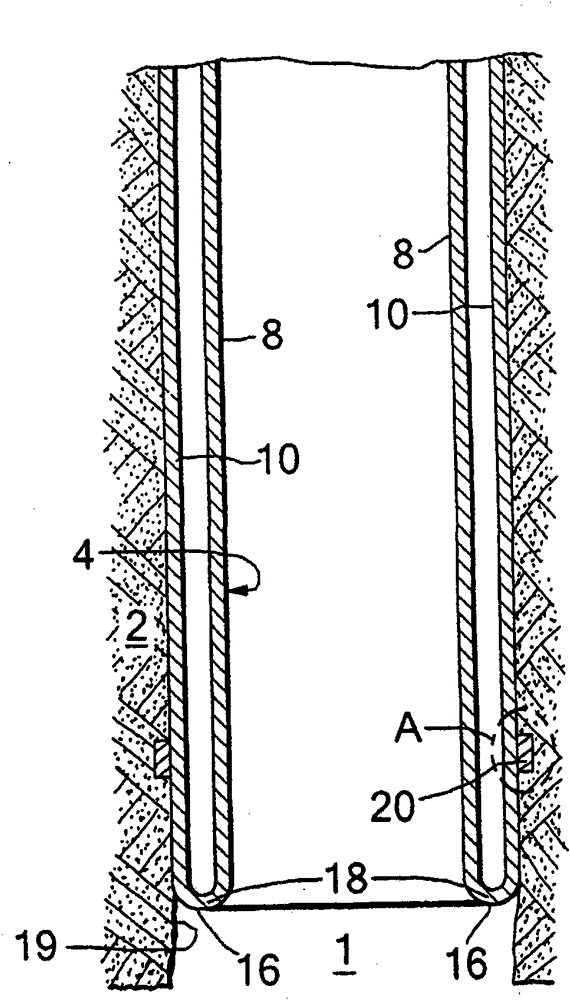

[0037] refer to Figure 1-3 , shows a longitudinal section of a first embodiment comprising a wellbore 1 extending into the formation 2 and a tubular element in the form of a liner 4 extending down into the wellbore 1 . The liner 4 has been partially radially expanded by eversion of the liner wall, thereby forming a radially expanded tubular portion 10 of the liner 4 having an outer diameter substantially equal to the borehole diameter. The remaining tubular portion 8 of the liner 4 extends concentrically within the expanded tubular portion 10 .

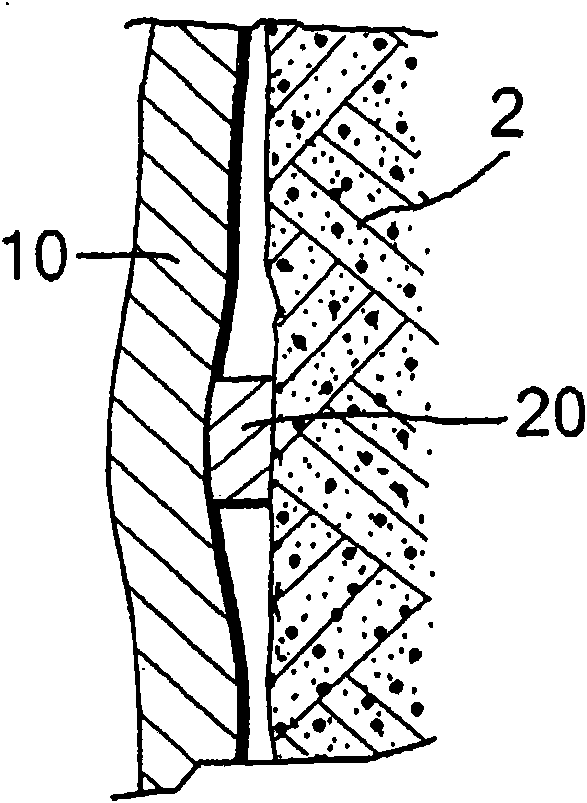

[0038] The wall portion of the liner 4 , due to its lower end everted, extends radially outward and axially in the opposite (ie upward) direction to form a U-shaped lower portion of the liner interconnecting the remaining liner portion 8 and the expanded liner portion 10 16. The U-shaped lower part 16 of the liner 4 defines a bending zone 18 of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com