Spindle box

A spindle box and spindle technology, applied in the field of CNC milling machines, can solve the problems of difficulty in automatic tool change, high design and installation requirements, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are only used to illustrate the technical solutions of the present invention.

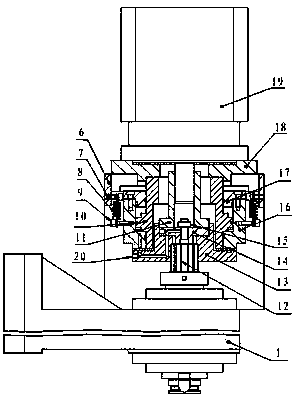

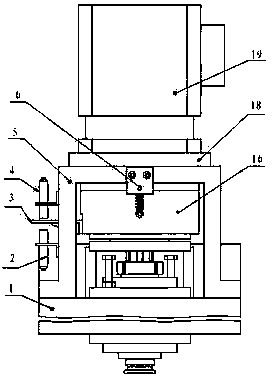

[0019] The main shaft box is characterized in that the motor support 5 is fixedly installed on the main shaft box 1, the motor plate 18 is fixed on the motor support 5, the main shaft motor 19 is fixed on the motor plate 18, and the main shaft motor 19 is directly connected with the main shaft 12; locking The nut 15 fixes the gland 14 on the main shaft 12, the gland 14 is fixed with the transmission sleeve 11 and the spline transmission sleeve 13 to form a coupling, and the spline transmission sleeve 13 has an air inlet 20; the transmission sleeve 11 and the spline transmission sleeve 13 The main shaft motor 19 is connected with a key, and the spline transmission sleeve 13 is connected with the main shaft 12 with a spline; the coupling can move up and down on the main shaft 12; the piston 10 is fixed on the motor plate 18, and the oil cylinder body 16 and the end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com