Wall brushing device of double-screw grooving machine

A grooving machine and double-helix technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of increasing labor and cost, and achieve an excellent effect of brushing the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

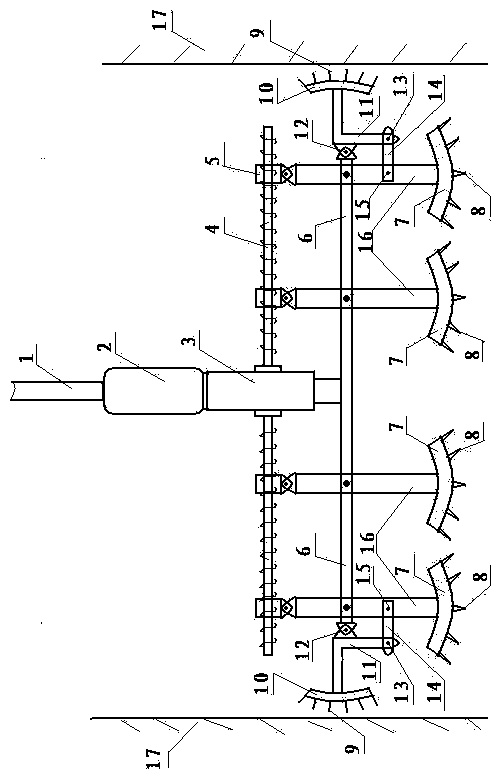

[0011] The accompanying drawing is a specific embodiment of the present invention, which includes two wall brush assemblies installed on the left and right sides of the groove forming machine, and the middle of the L-shaped brush handle 11 of each wall brush assembly is hinged by pin A12 Support bar 6, the lower end of the L-shaped wall brusher is hinged through one end of the connecting rod 14 by pin B, the other end of the L-shaped wall brusher is fixed with a brush holder 10, and the brush holder is provided with a plurality of wire brushes, and the other end of the connecting rod 14 One end is hinged upright 16 by pin C15.

[0012] The working principle of the double-helix grooving machine is: the motor drives the double-screw forward and reverse through the gearbox, drives the helical jacket to reciprocate left and right, and the helical jacket drives the vertical rod to swing left and right to form grooves during the movement. The vertical rod also pushes and pulls the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap