A crane track measuring device

A measuring device and crane technology, which is applied to the measurement of the height deviation and level deviation of the crane track, the span difference between the left and right tracks, and the measurement field of the height difference. It can solve the problems of low detection efficiency, difficult track detection, and difficulty in erecting detection equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

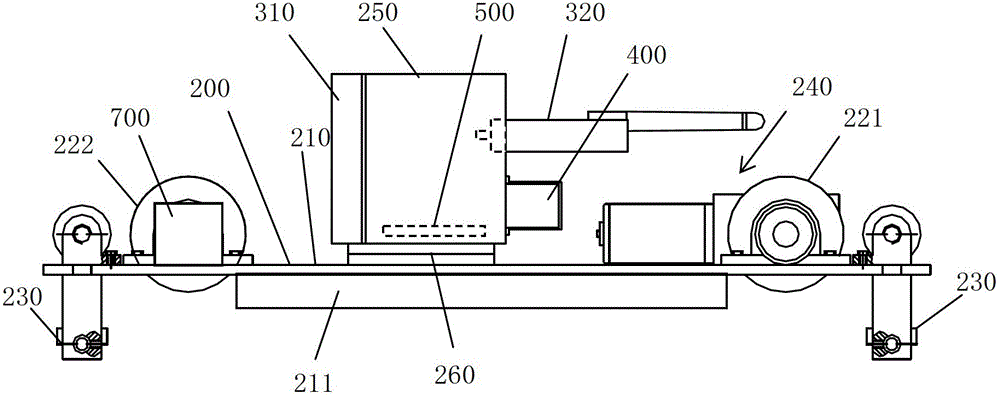

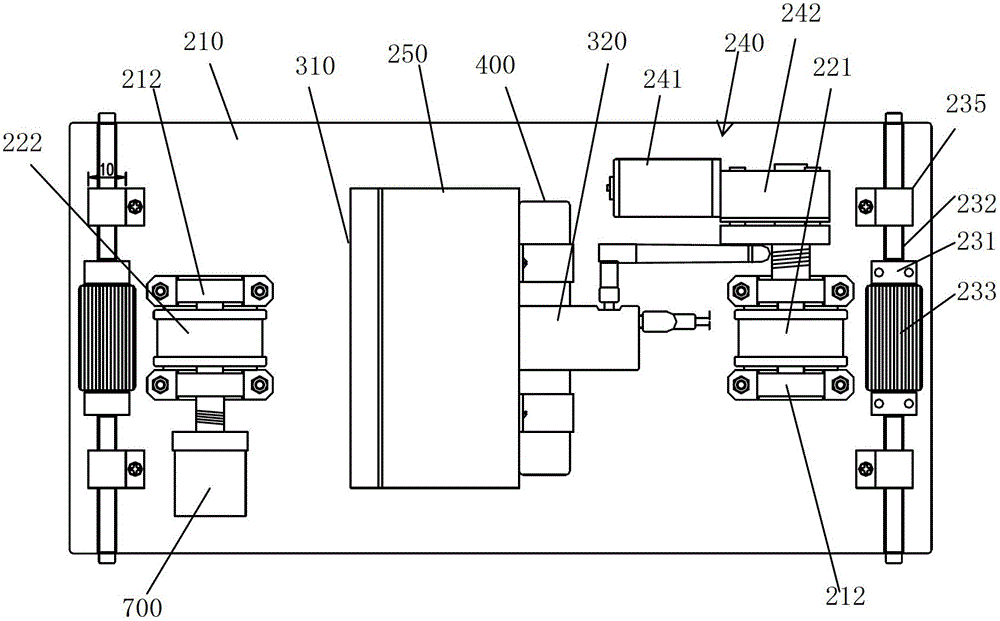

[0025] like Figure 1 to Figure 4 As shown, a crane track measuring device includes a trolley 200 , a laser receiving screen 310 , a video device 320 , an on-board controller 500 , a distance measuring device 700 , and a power supply 400 .

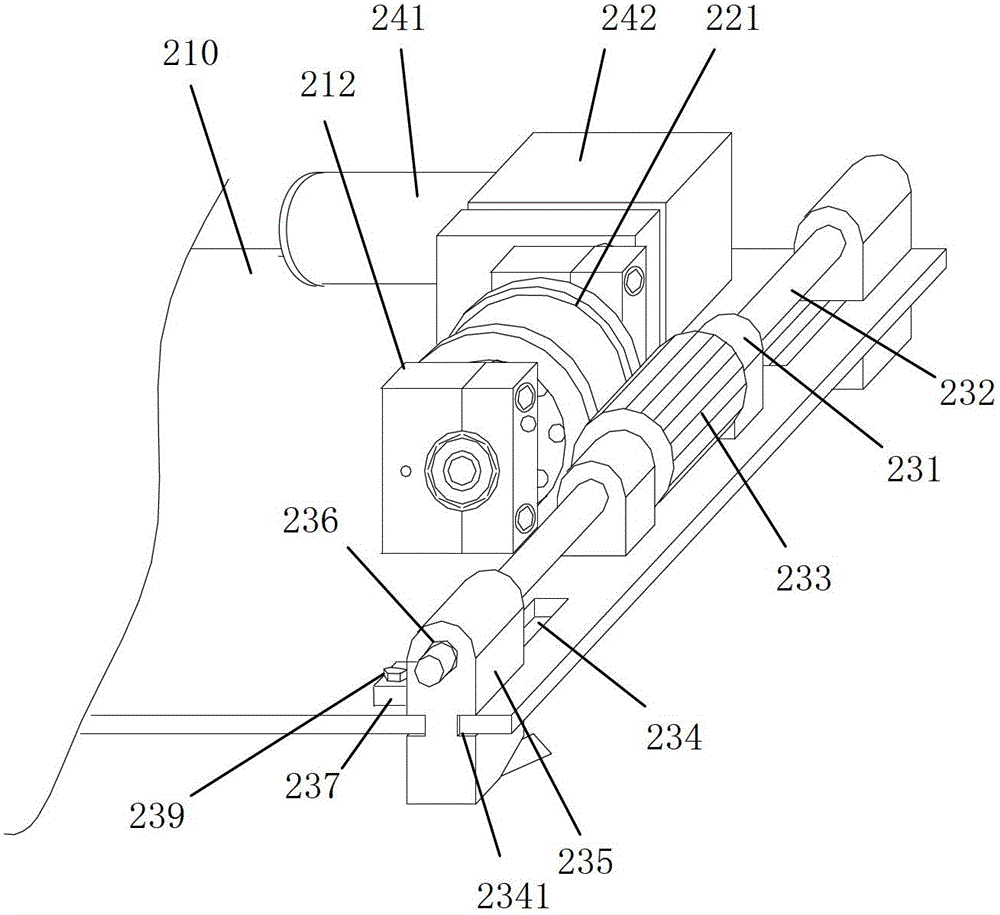

[0026] like figure 1 and figure 2 As shown, the trolley 200 includes a bottom plate 210 , two surface wheels, four side guide wheels 230 , and a driving device 240 .

[0027] The bottom plate 210 has a rectangular shape. Bottom plate 210 has a hole in the middle position of the front part and the rear part (for convenience of description, take the left part of the dolly 200 as shown in the figure as the laser emitting device as the front part, and the right part of the car 200 as shown in the figure is the rear part of the laser emitting device), in the hole Both sides are provided with bearing seats 212, while the two surface road wheels are located above the bottom plate and in the opening, and are supported by the bearings in the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com