Process for producing hardened bodies from hydraulically setting compositions

A composition and hydraulic technology, which is used in the field of preparing hardened bodies from hydraulic compositions, can solve problems such as huge energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

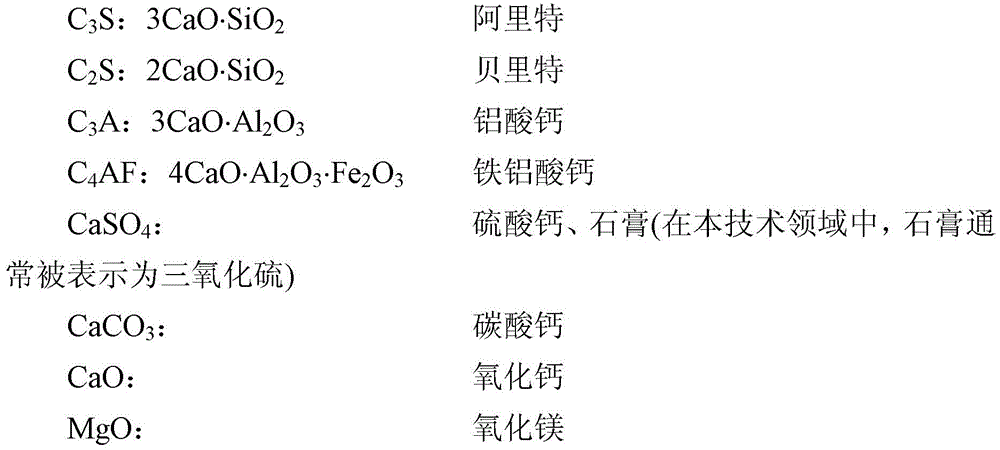

[0020] The present invention includes an embodiment of a method for preparing a hardened body of a hydraulically setting composition comprising:

[0021] Step 1 of preparing a hydraulic composition by mixing glycerin, a binder, and water, using raw materials of a hydraulic composition containing a substance containing sulfate ions such that the molar ratio of sulfate ions to glycerin, i.e., sulfate ions / glycerin, is 5.0 to 20, and the content of sulfate ions is 3.0 to 15 parts by weight relative to 100 parts by weight of the cement; and

[0022] Step 2 of curing and hardening the hydraulic composition obtained in step 1.

[0023] In the present invention, the hydraulic composition contains sulfate ions. Sulfate ions can be mixed with cement and water. Sulfate ions may be included in the cement and additional sulfate may optionally be added in step 1 . The raw material for the hydraulically setting composition obtained in step 1 may contain glycerin, binder and water, and th...

Embodiment 1 and comparative example 1

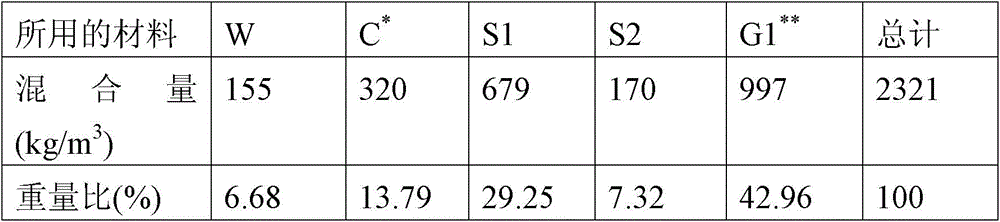

[0209] Concrete was prepared using cement (C1) as raw material and tested (Tables 1, 2 and 2B).

Embodiment 2 and comparative example 2

[0211] Concrete was prepared using cement (C2) as raw material and tested (Tables 1 and 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com