Swivel Pin Mechanism

A technology of slanted pins and slanted pin seats, applied in the field of rotatable slanted pin mechanisms, can solve problems such as undercut 11 cannot be formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

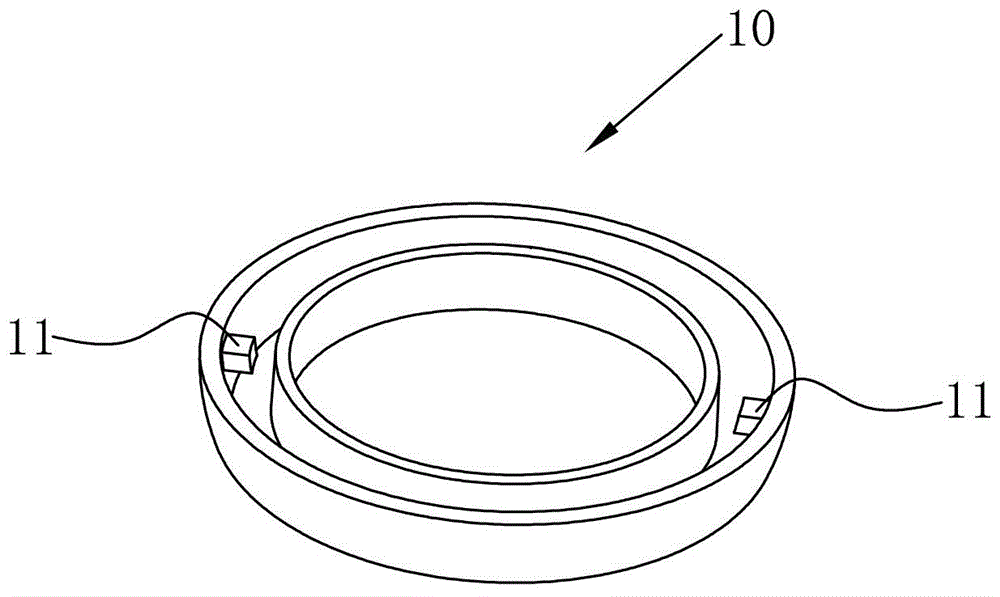

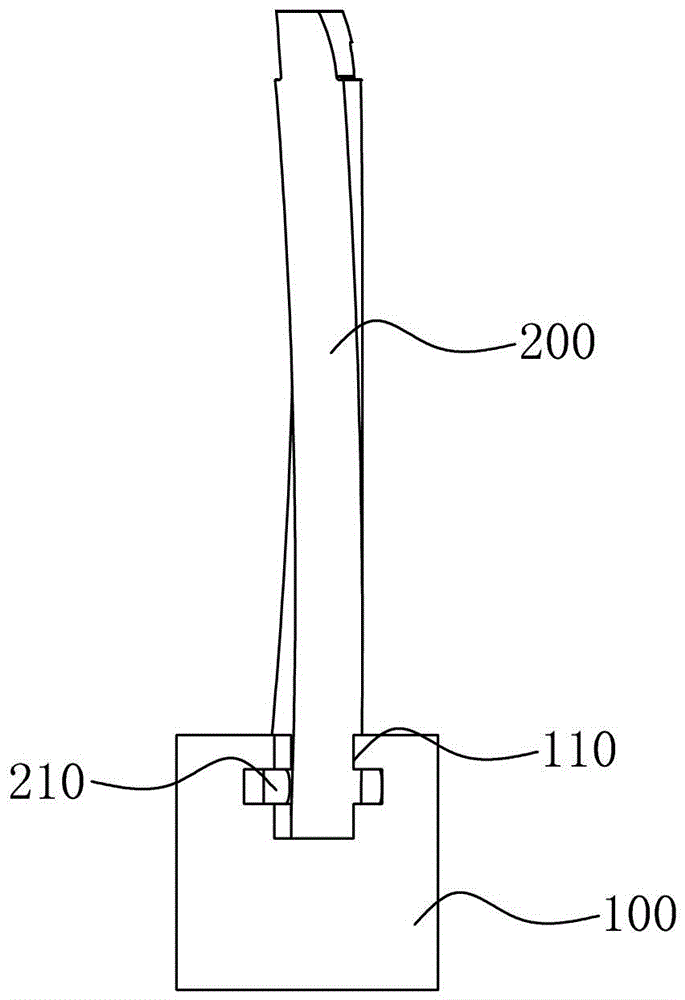

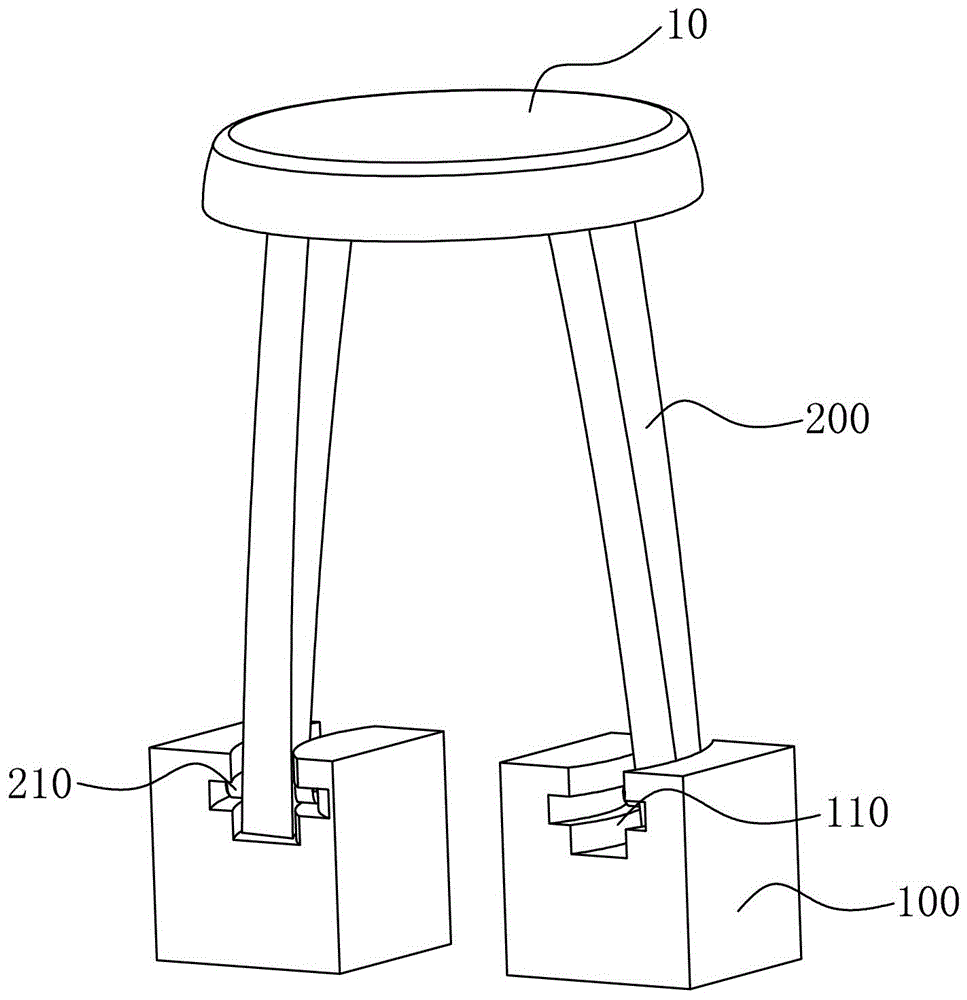

[0022] see figure 2 , image 3 and Figure 4 As shown, they respectively depict the structural schematic diagram of the swivel pin mechanism of the present invention, the schematic diagram of one angle when the product is formed by the swivel pin mechanism of the present invention, and the schematic diagram of another angle when the product is formed by the swivel pin mechanism of the present invention.

[0023] The rotary oblique pin mechanism of the present invention is applied in a mold. In this embodiment, the annular product 10 is provided with two barbs 11. Therefore, two sets of rotary oblique pin mechanisms are provided when forming the barbs 11. The swivel pin mechanism consists of:

[0024] The oblique pin seat 100, the oblique pin seat 100 is arranged on the ejection plate of the mould, and the oblique pin seat 100 is provided with an arc-shaped slot 110, the section of which is cross-shaped. When the cross-shaped arc-shaped slot 110 is used, the T-shaped arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com