Transfer car for grains

A transfer vehicle and grain technology, applied in the field of transport vehicles, can solve the problems of limited manual physical strength, bulky loading conveyor, and low loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

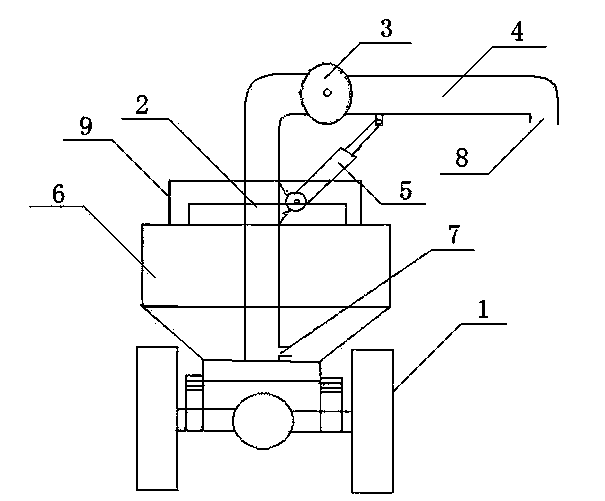

[0013] Such as figure 1 A kind of grain transit car shown, comprises car body 1 and the conveying mechanism that is installed on the car body, hydraulic mechanism, and described conveying mechanism includes the vertical auger conveying device 2 that connects in sequence, universal coupling shaft 3, horizontal auger The conveying device 4; the hydraulic mechanism includes a hydraulic control device and a hydraulic rod 5, and the hydraulic rod 5 is connected between the vertical auger conveying device 2 and the horizontal auger conveying device 4; the vertical auger conveying device 2 and the compartment 6 of the car body The bottom is connected in rotation, and the vertical auger conveying device 2 is provided with a grain inlet 7 near the bottom of the compartment 6, and the grain outlet 8 is set at the other end of the horizontal auger conveying device 4 and the universal joint shaft 3 connection end.

[0014] The grain outlet 8 is vertically connected with the horizontal aug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap