Pipeline connector

A technology of pipe joints and channels, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, through components, etc., can solve the problems of difficult to guarantee the quality of the connection, difficult to guarantee the quality, unusable thermal connection, etc. Convenient, fast and leak-free connection, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

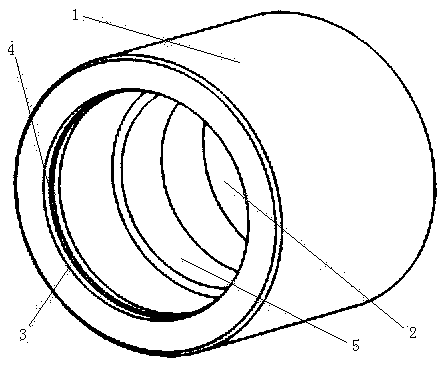

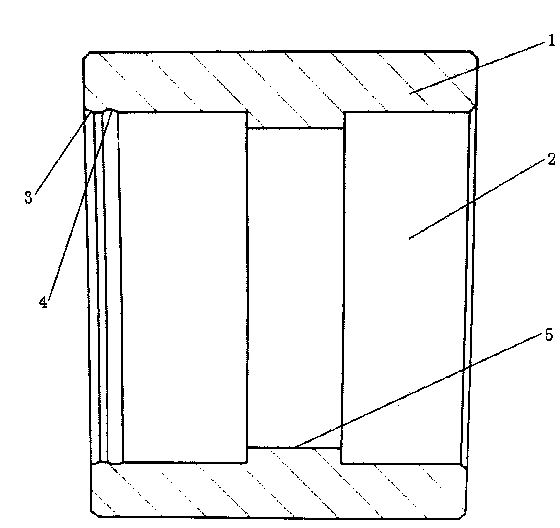

[0022] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0023] Such as figure 1 and figure 2 As shown, a pipe joint includes a joint body 1, and the middle part of the joint body 1 is a through channel 2; the inner wall of the channel at one side of the joint body 1 is provided with a sealing engaging part, and the sealing engaging part The part includes an outer convex ring 3 and an inner concave ring 4 whose cross sections are sequentially formed by an outer convex arc and an inner concave arc; Positioning ring 5, said limiting ring 5 is an outer convex ring whose cross section is a rectangular boss.

[0024] Compared with the prior art, the beneficial effect of the present invention is that the arrangement of the outer convex ring 3 and the inner concave ring 4 ensures the smoothness of the sealing engaging part, facilitates the placement of sealing parts such as sealing gaskets, and the sealing after the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com