Plate friction introduction mechanism

A technology of inserting plates and friction wheels, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as difficult installation and maintenance, low construction efficiency, broken chains and broken ropes, and reduce equipment and construction costs. The effect of reducing the weight of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

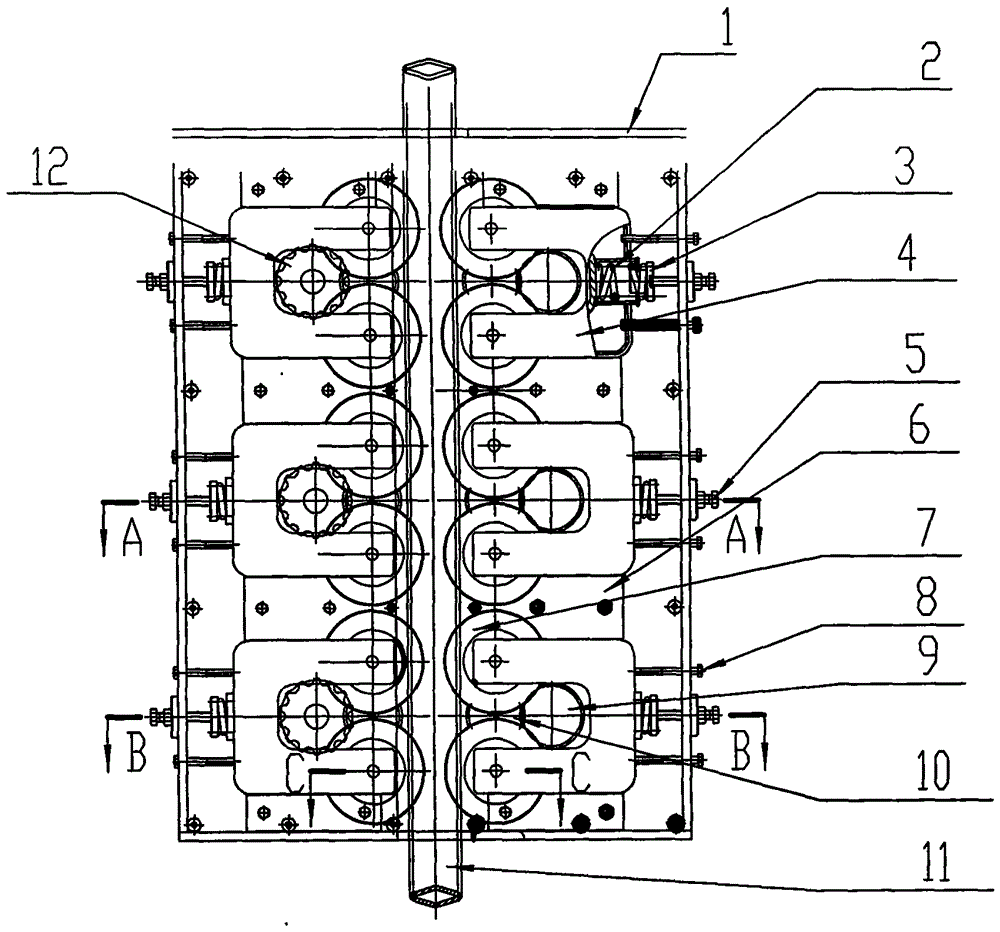

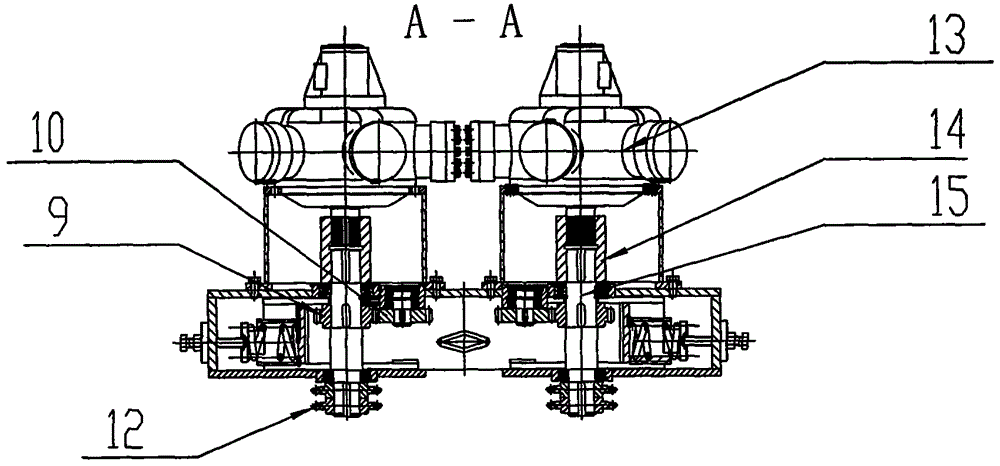

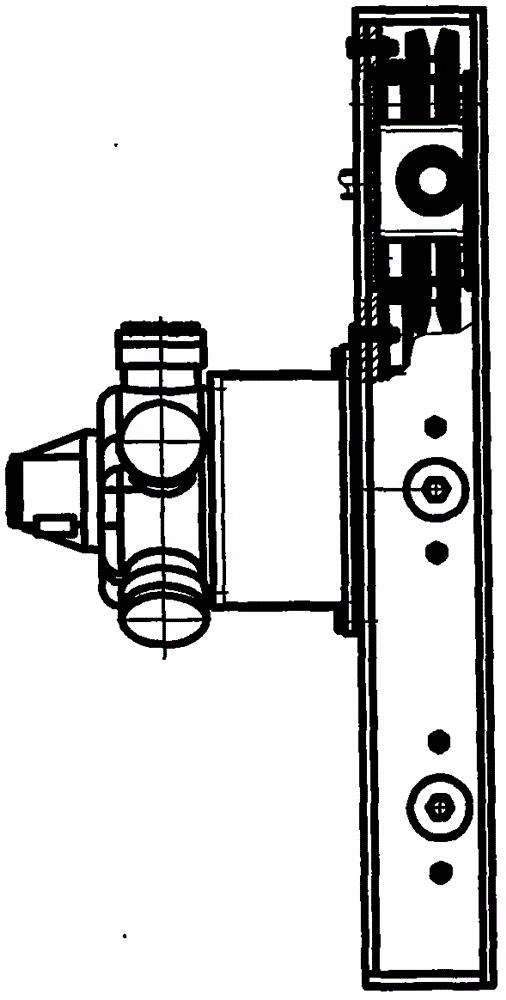

[0023] Reference Figure 1 to 5 , The sliding plate friction introduction mechanism includes a box body 1 and a hydraulic motor 13. The box body 1 is equipped with a pressure spring 2, a friction wheel seat body 4 and a driving gear 9, and the box body 1 is connected to the friction wheel seat through the pressure spring 2. Body 4, the friction wheel seat body 4 is equipped with one or two groups of friction wheels 7, the hydraulic motor 13 drives the driving gear 9, and the driving gear 9 drives the one or two groups of friction wheels 7 to rotate in the same direction.

[0024] As a further preferred embodiment, the box body 1 is provided with the hydraulic motor 13, the pressure spring 2, the friction wheel seat body 4, the friction wheel 7 and the driving gear 9 symmetrically to each other.

[0025] Further as a preferred embodiment, the friction wheel seat body 4 symmetrically arranged opposite to each other is provided with two or more than two groups, the driving gear 9 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com