A reverse digging and penetration blasting method that does not damage the existing shaft when the shaft is extended

A back-drilling and non-damaging technology, which is applied in blasting and other directions, can solve the problems of wellbore facilities, wellbore and wellbore damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

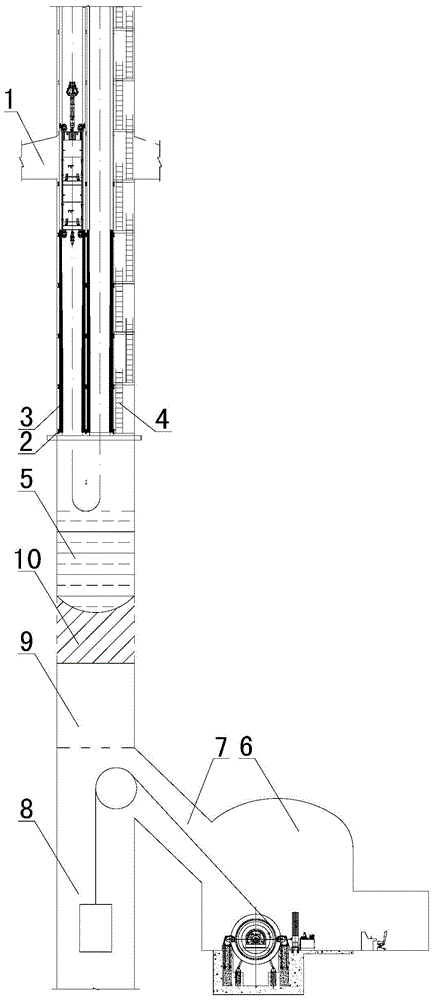

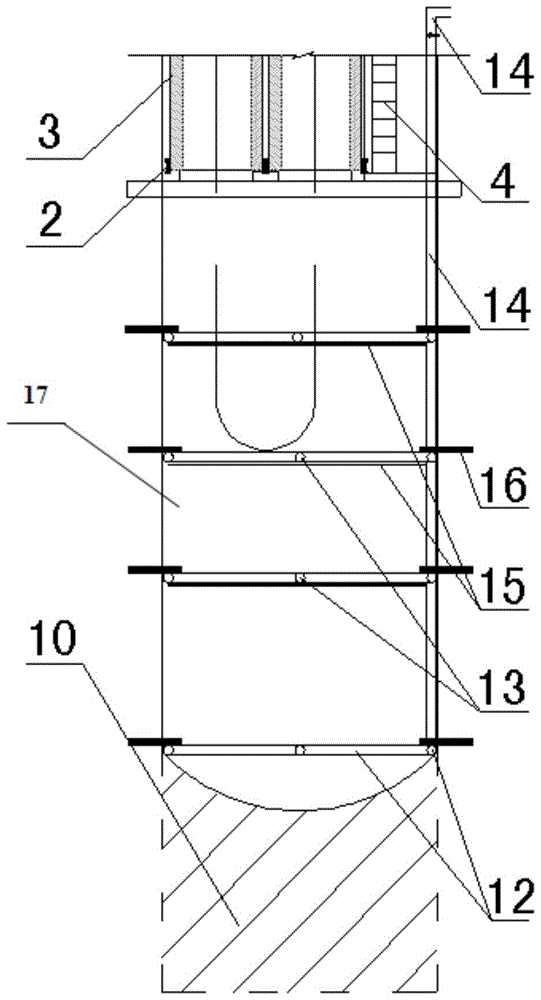

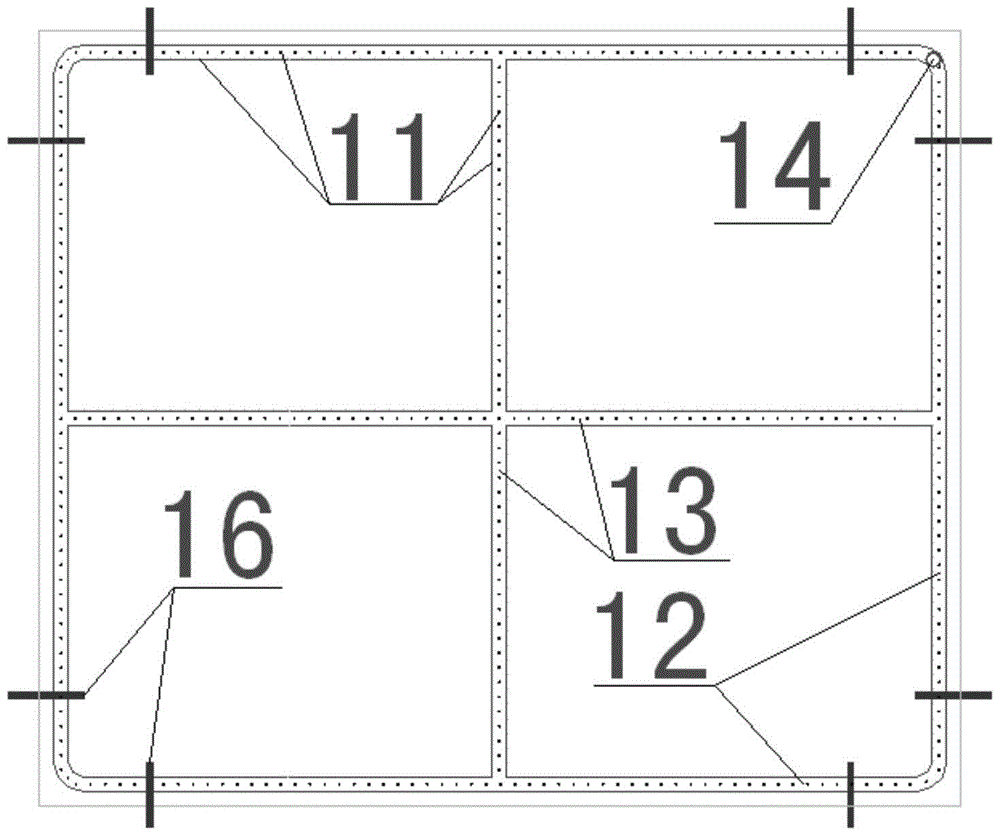

[0038] Below in conjunction with the accompanying drawings, a back-cutting and penetration blasting method of the present invention that does not damage the existing wellbore when the shaft is extended will be further described in detail.

[0039] Depend on figure 1As shown in the schematic diagram of the system of a reverse digging and penetration blasting method that does not damage the existing wellbore when the shaft is extended, it can be seen that the bottom part of the existing shaft includes the lowest middle section of the roadway 1, the existing shaft tank beam 2, the existing There are shaft tanks 3, existing shaft ladders 4, and existing shaft bottom water nests 5. When the wellbore is extended, generally during the normal production period of the existing wellbore 17, the extended well digging hoist chamber 6 and the extended well digging ropeway 7 are excavated normally, and then the extended wellbore 8 is dug; , finally carry out back excavation and penetration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com