A split type two-stage garbage compressor compression head and compressor

A garbage compactor, compression head technology, applied in the direction of presses, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

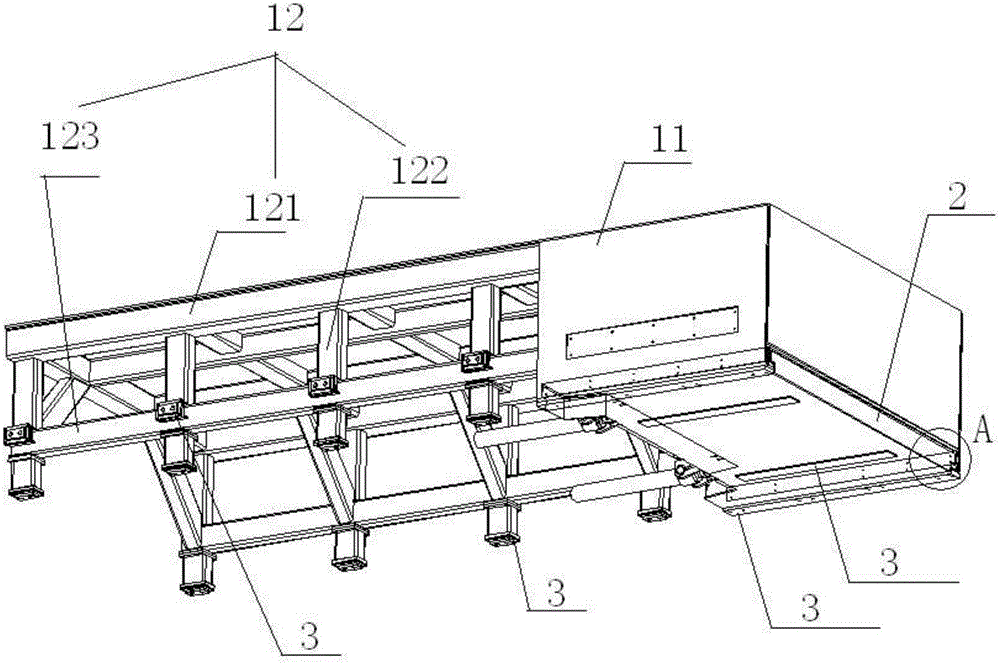

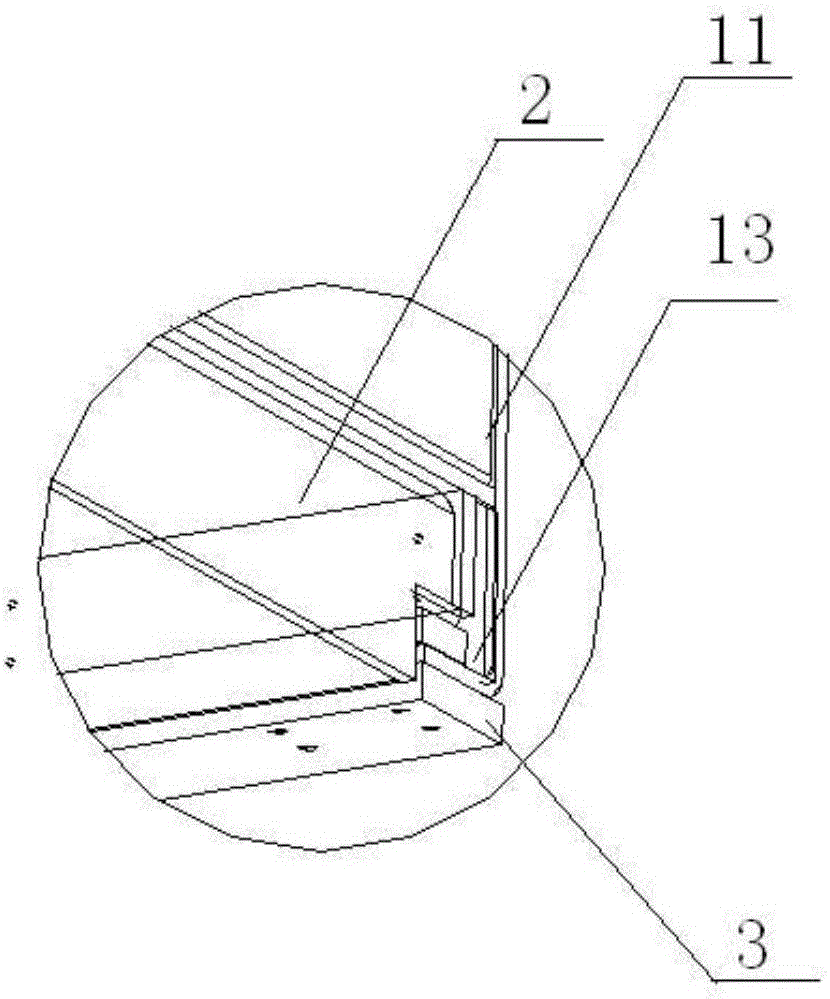

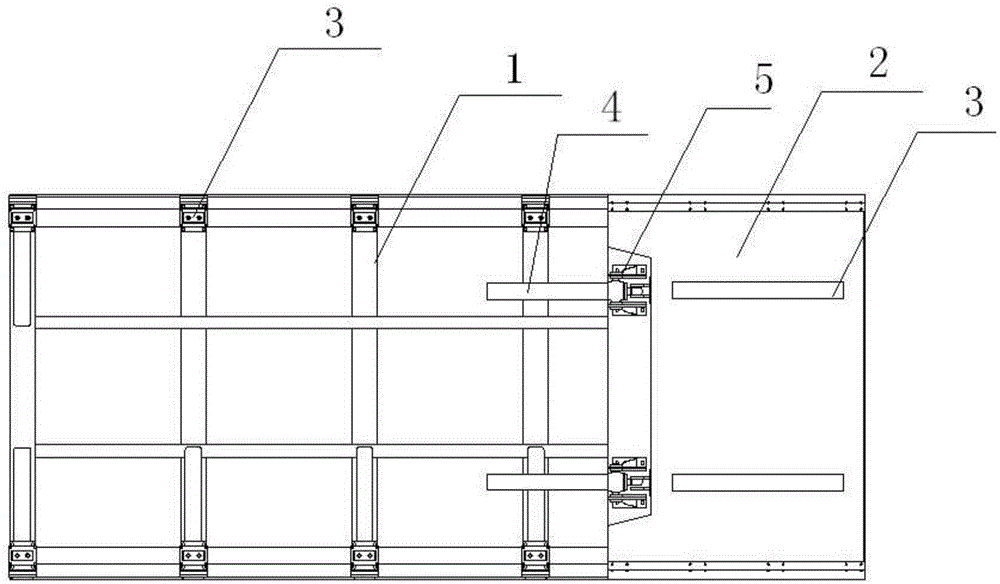

[0037] Such as Figure 1-7 Shown: the split type two-stage garbage compressor compression head of the present invention is composed of main compression head 1, auxiliary compression head 2, sliding friction pair 3, oil cylinder 4, oil cylinder mounting bracket 5 and other components.

[0038] The auxiliary compression head 2 is located below the main compression head 1 and forms a double-layer compression head with the main compression head 1 . In design, the main compression head 1 and the auxiliary compression head can be selected to be completely separated, and then each is controlled by a telescopic device to advance synchronously or independently. In this embodiment, the main and auxiliary compression heads 1 and 2 are designed as one, that is, the extension and retraction of the main compression head 1 and the auxiliary compression head 2 can be controlled by the telescoping device of the main compression head 1 . Control secondary compression head 2 to stretch out sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com