Fuel injector sealing ring reliability testing device and method

A test device and fuel injector technology, which is applied in the direction of measuring device, machine/structural component test, mechanical component test, etc., can solve the problems of single environment, low test accuracy and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

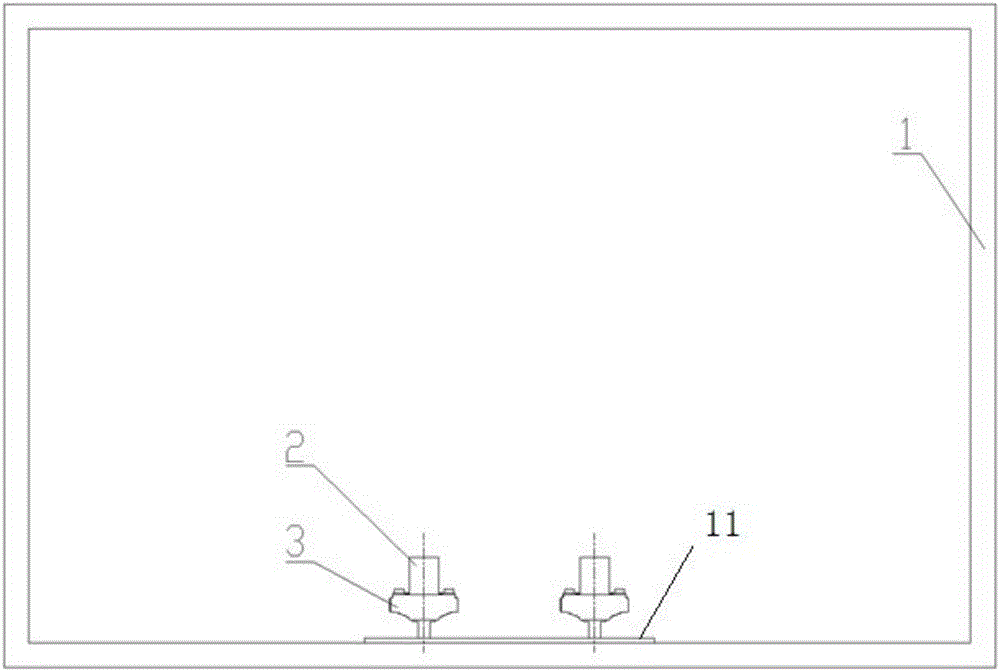

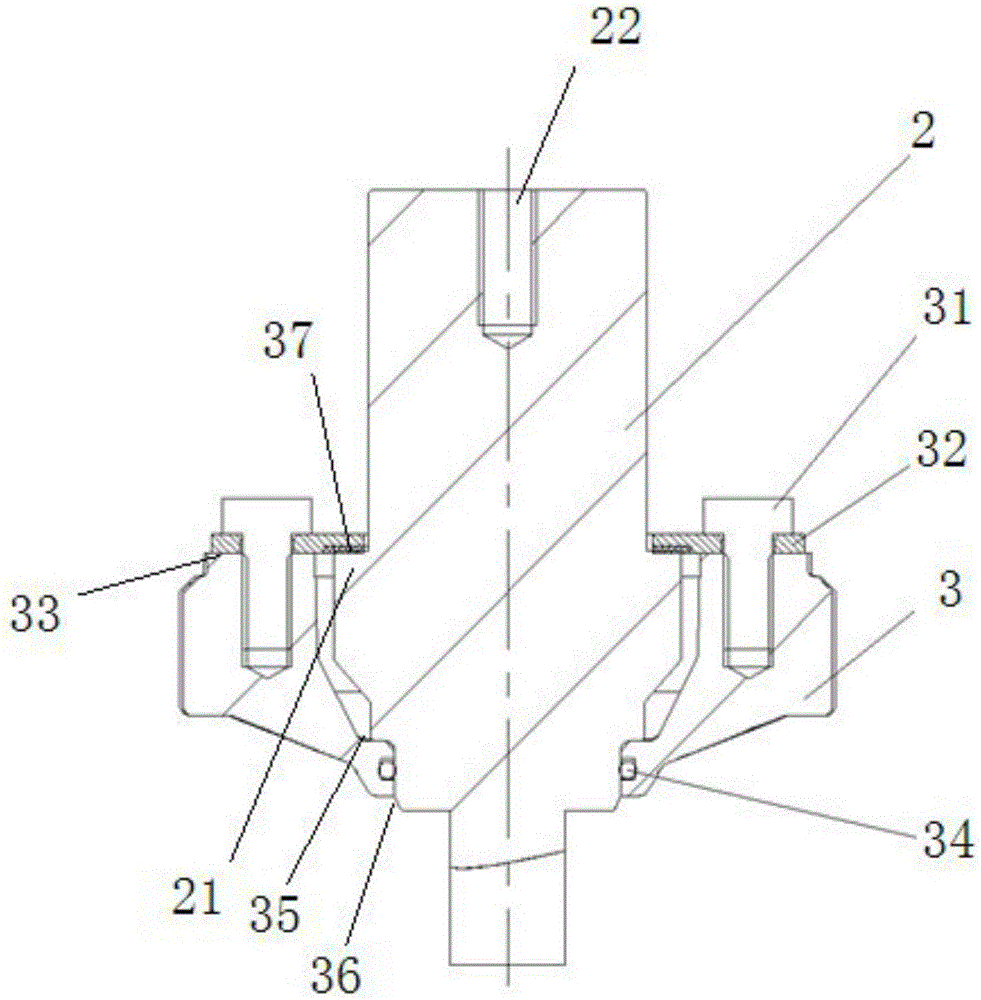

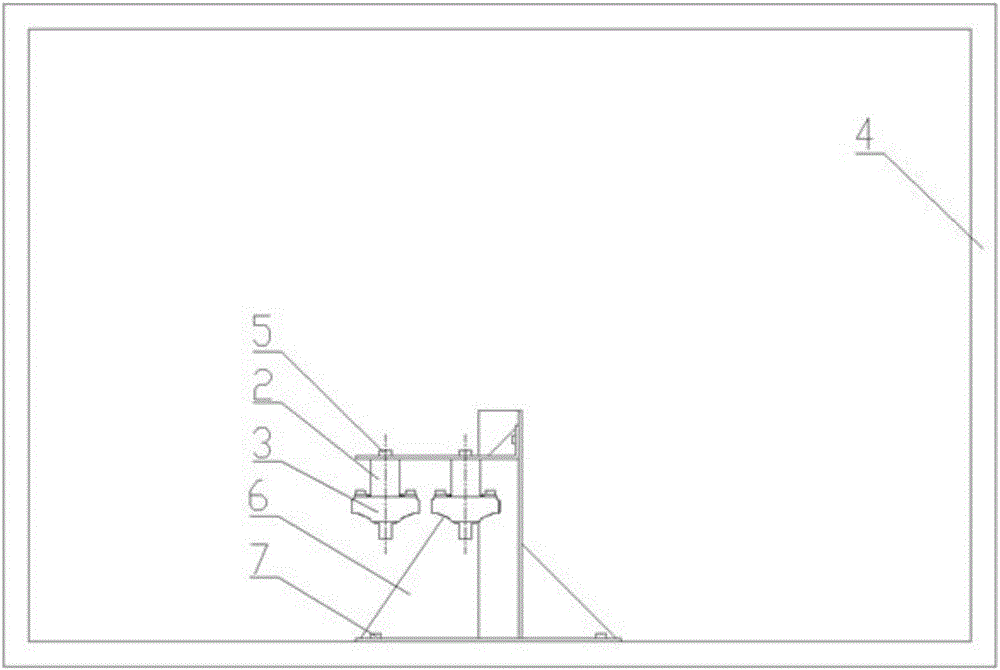

[0013] Embodiment: A reliability test device for a fuel injector sealing ring according to the present invention, comprising a pair of pressure plates 32, a fuel injector simulation part 2 provided with a shaft shoulder 21, and a stepped mounting surface 33, a thrust surface 35 and a mounting hole 36 seal ring 3, characterized in that: the fuel injector simulation part 2 is located in the installation hole 36, one end of the pressure plate 32 is fixed on the stepped installation surface 33 by the pressure plate bolt 31, and the other end of the pressure plate 32 is connected to the The upper end surface of the shaft shoulder 21 is attached, the thrust surface 35 is attached to the lower end surface of the shaft shoulder 21, and a single-sided vulcanized rubber layer 37 is provided between the other end of the pressure plate 32 and the upper end surface of the shaft shoulder 21. The inner wall of the installation hole 36 is provided with a sealing ring 34 matching with the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com