Air conditioner and control method for the air conditioner

A technology for air conditioners and control valves, applied in heating and ventilation control systems, refrigerators, heating methods, etc., can solve the problems of large heat exchange area of indoor heat exchangers and accumulation of refrigerants in indoor heat exchangers, so as to avoid suction and other problems. The gas specific volume rises, avoids the reduction of exhaust pressure and return gas pressure, and solves the effect of excessive heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

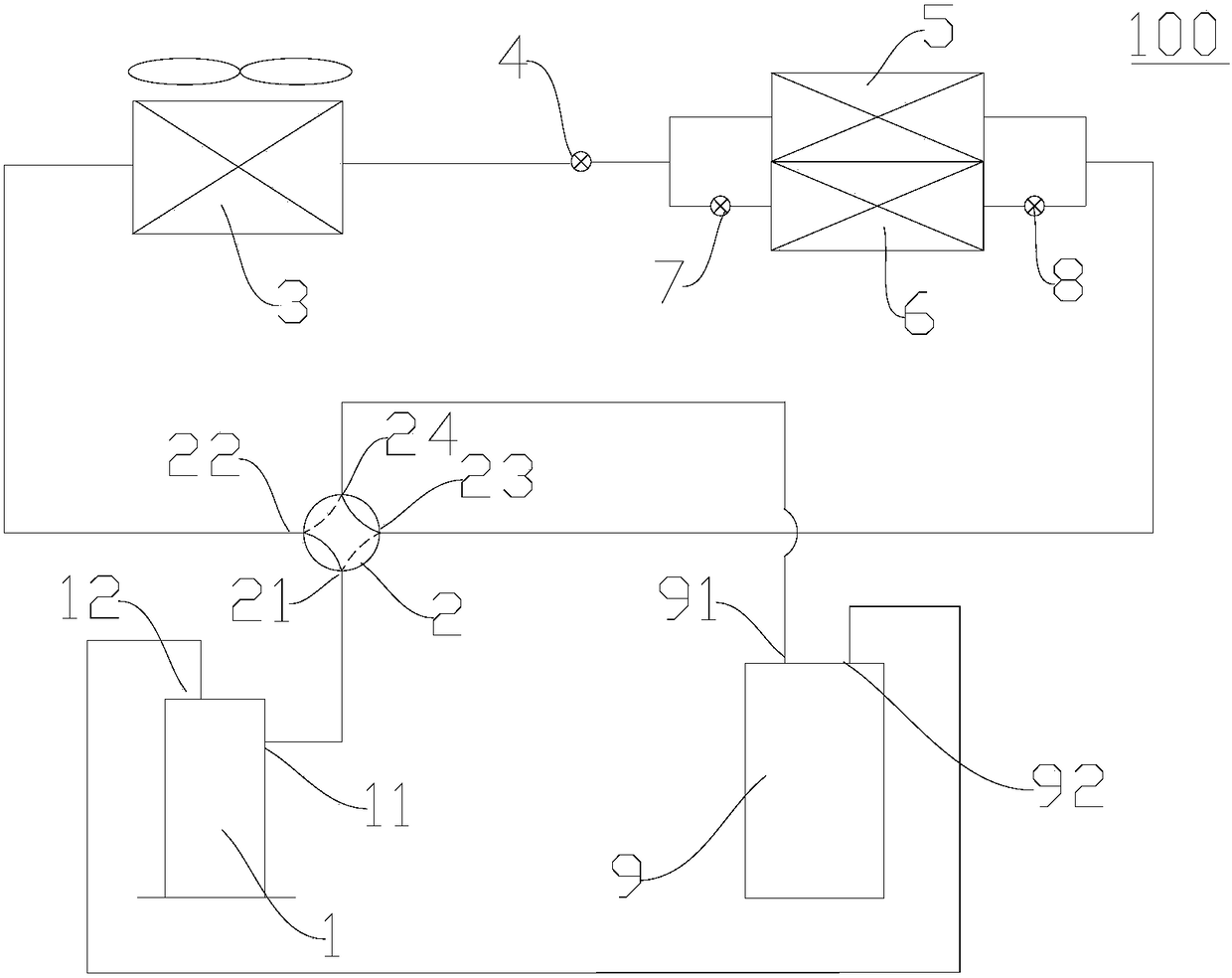

[0054] Such as figure 1 As shown, the air conditioner 100 in this embodiment includes a compressor 1, a reversing assembly 2, an outdoor heat exchanger 3, a throttling element 4, and a first indoor heat exchanger connected in parallel in the same indoor unit 5 and the second indoor heat exchanger 6, the first control valve 7 and the second control valve 8. Among them, the first control valve 7 and the second control valve 8 are both solenoid valves. The throttle element 4 is an electronic expansion valve.

[0055] Specifically, the compressor 1 has an exhaust port 11 and a return port 12. The reversing assembly 2 includes a first valve port 21 to a fourth valve port 24. When the air conditioner 100 is cooled, the first valve port 21 and the second valve port 22 The third valve port 23 is in communication with the fourth valve port 24. When the air conditioner 100 is heating, the first valve port 21 is in communication with the third valve port 23 and the second valve port 22 and...

Embodiment 2

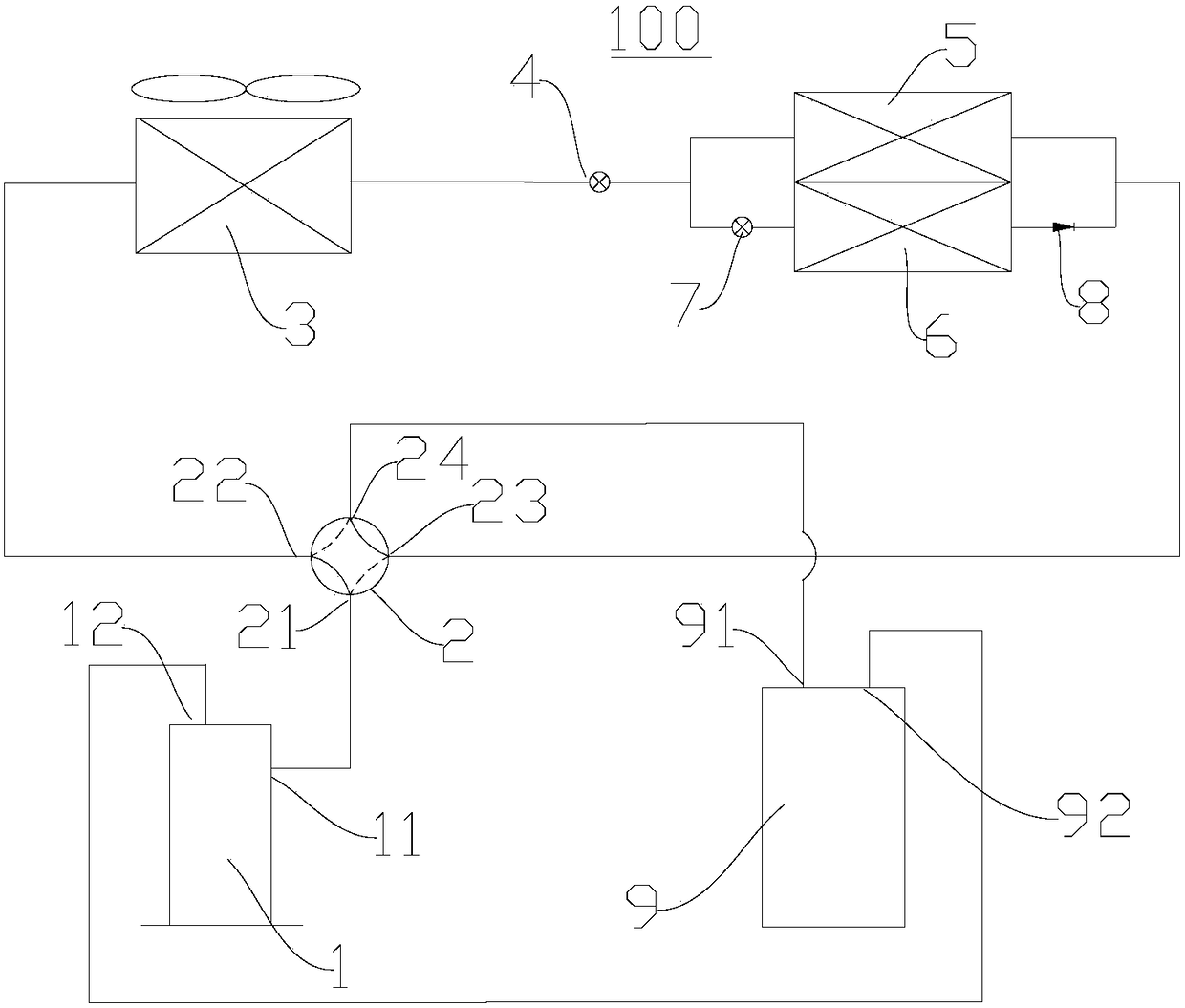

[0066] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the second control valve 8 is a one-way valve that communicates unidirectionally in the direction from the second indoor heat exchanger 6 to the third valve port 23. The working principle of the air conditioner 100 in the cooling mode in this embodiment is the same as that in Embodiment 1 above.

[0067] It is understandable that when the air conditioner 100 is in the heating mode, since the second control valve 8 is a one-way valve, there is always no refrigerant flow in the direction from the third valve port 23 to the second indoor heat exchanger 6 The second indoor heat exchanger 6, that is, the second indoor heat exchanger 6 is always in a shielded state. Specifically, when the air conditioner 100 needs to turn on the heating mode, first switch the operation mode of the air conditioner 100 to the cooling mode, and close the first control valve 7 to prevent the refrigerant from ...

Embodiment 3

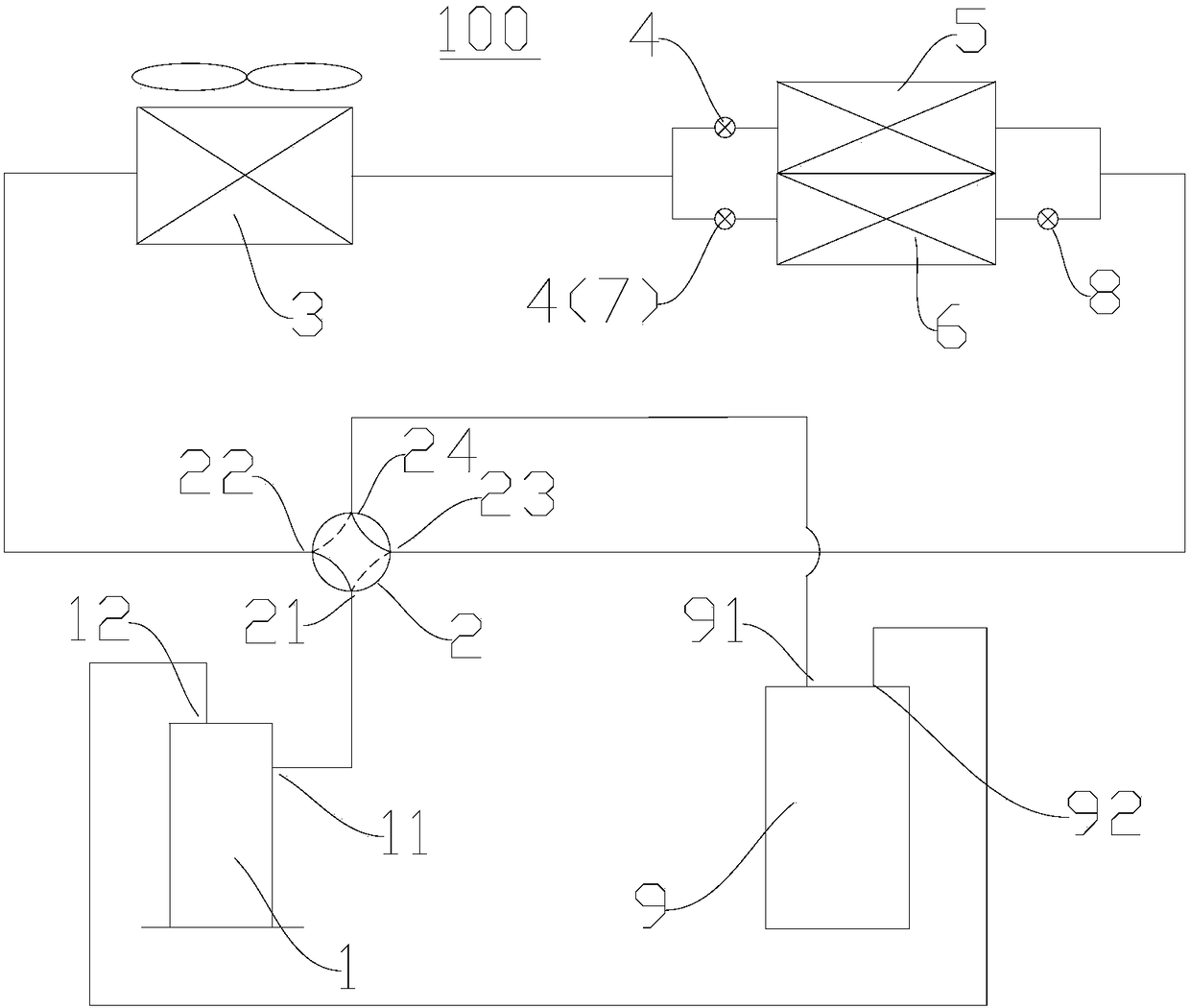

[0069] Such as image 3 As shown, the air conditioner 100 in this embodiment includes a compressor 1, a reversing assembly 2, an outdoor heat exchanger 3, two throttling elements 4, and a first indoor heat exchange unit connected in parallel in the same indoor unit. The device 5 and the second indoor heat exchanger 6, the first control valve 7 and the second control valve 8. The second control valve 8 is a solenoid valve.

[0070] Specifically, the compressor 1 has an exhaust port 11 and a return port 12. The reversing assembly 2 includes a first valve port 21 to a fourth valve port 24. When the air conditioner 100 is cooled, the first valve port 21 and the second valve port 22 The third valve port 23 is in communication with the fourth valve port 24. When the air conditioner 100 is heating, the first valve port 21 is in communication with the third valve port 23 and the second valve port 22 and the fourth valve port 24 are in communication. The first valve port 21 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com