Dynamic seal for fuel injector needle check

A fuel injector and check valve technology, which is applied to fuel injection devices, special fuel injection devices, engine components, etc., can solve problems such as understanding or solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

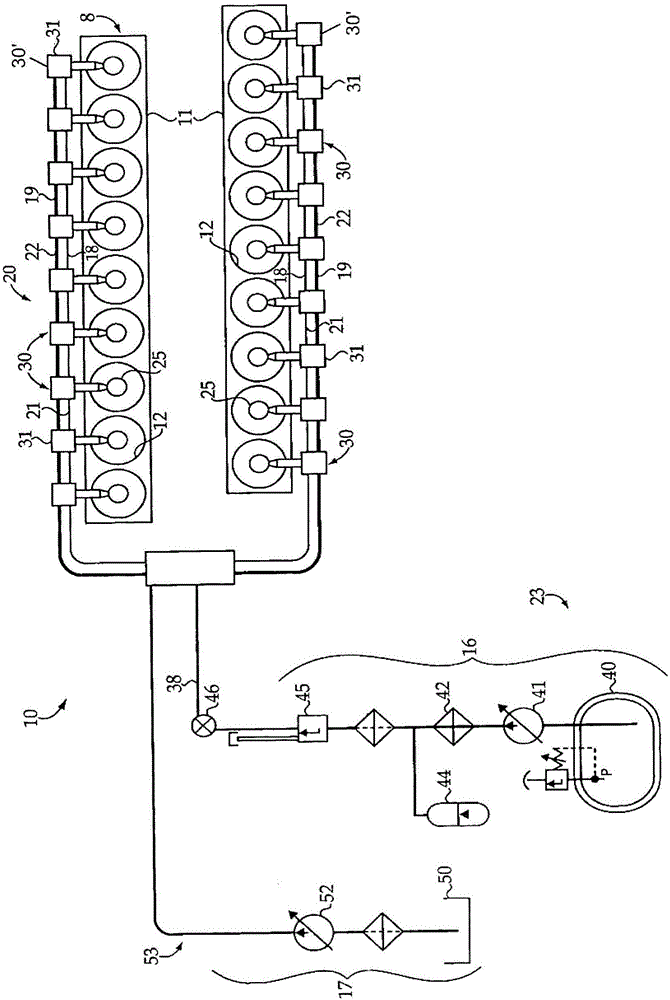

[0021] Aspects of the invention will now be described with reference to the drawings, wherein like reference numerals refer to like elements throughout, unless otherwise indicated.

[0022] Figure 1-3 Engine 8 and dual fuel engine system 10 are shown. Engine 8 may include an engine housing 11 which may define a plurality of engine cylinders 12 . Dual fuel engine system 10 may include dual fuel system 20 mounted to engine housing 11 of engine 8 . Dual fuel system 20 may include at least one fuel injector 25 positioned to inject directly into at least one cylinder of plurality of engine cylinders 12 . Gaseous fuel common rail 21 and liquid fuel common rail 22 may be fluidly connected to each of at least one fuel injector 25 and are part of gaseous fuel subsystem 23 and liquid fuel subsystem 53 , respectively, of dual fuel system 20 . Liquid fuels may include distillate diesel fuel, biodiesel, dimethyl ether, gasoline, ethanol, liquefied natural gas, liquefied propane, combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com