Vehicle-mounted type sunscreen thermal-insulation hood

A technology for sun protection, heat insulation, and car cover, which is applied to vehicle parts, removable outer sheaths, transportation and packaging, etc. It can solve the problems of affecting the speed of sewing processing, bulky size, and increasing the difficulty of sewing processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

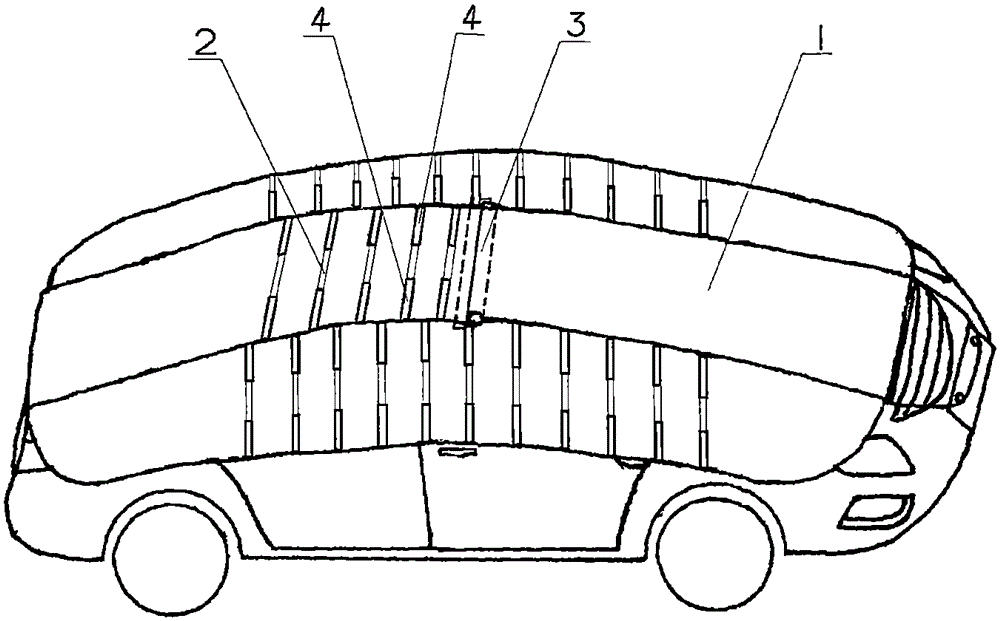

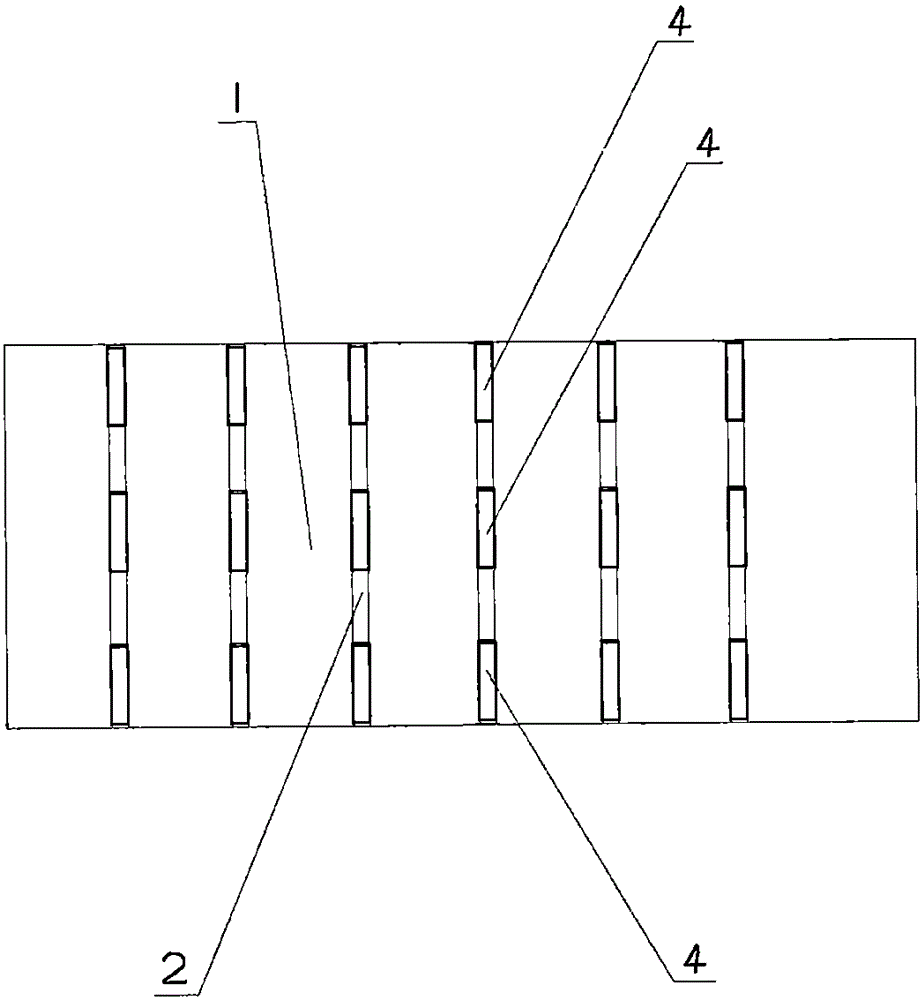

[0008] refer to figure 1 , a vehicle-mounted sun-proof and heat-insulating car roof provided by the present invention includes a car sunshade cloth body 1, a cloth body support strip 2, and a cloth body winding mechanism 3. The car sunshade cloth body 1 is provided with mutually parallel and spaced Strip cloth cover 4, the cloth body support bar 2 is installed in the strip cloth cover 4, the automobile sunshade cloth body 1 on both sides can be turned over and folded on the automobile sunshade cloth body 1 in the middle, and the automobile sunshade body after folding The cloth body 1 can be wound on the cloth body winding mechanism 3 .

[0009] refer to figure 1 , the strip-shaped cloth cover 4 is intermittently distributed on the automobile sunshade cloth body 1 along the direction of the strip-shaped length, and each intermittently distributed strip-shaped cloth cover 4 is left to allow the cloth body support strip 2 to be inserted The opening of the cloth body support str...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap